Flaman Rentals Blog

RSS feed

Categories

Recent activity

- What's it like being a Flaman Rental Dealer?

- A Brief History of the Newest Flaman Store in Swift Current

- Disney's NEW Leadership Excellence Training Course

- Disney's Approach To Quality Service

- Disney's Approach To Quality Service

- Trailering 'Rules of the Road' Updated

- 10th Annual Frank J. Flaman Foundation Gala 2016

- Why Frank Cares

Authors

Archive

Three Phase Electricity for Grain Handling

Posted by Jeff Brown Nov 06, 2023

Three-Phrase Grain Handling Power. Doable. Valuable.

More acres seeded might mean more bushels brought into your bin yard. But it doesn't have to mean more work and expense. As farming grows, new technologies emerge to boost your grain operation's speed and efficiency.

Technology Boosts Productivity.

Grain Dryers like our AGI NECO and Oakland models are designed to run continuously and safely. There's no need for you to spend your time or hire a hand to supervise them. And with remote monitoring systems, you can spend more time working in the field.

The same goes for the Walinga Blower System. Its airflow can move dried grain to your dry bins at rates of up to 2,000 bushels an hour. Achieving those higher volumes depends on the size of your piping and your motor's horsepower. The latter can be a sticking point for many farmers.

Amping Up Your Operation

Most farming operations are still wired for single-phase power. The high-volume systems mentioned above require three-phase power, which hits its peak amplitude three times as often as single-phase for three times the power output. It’s the optimum circuit for power generation. Higher-phase systems prove too complicated and expensive to be worth pursuing.

Despite its benefits, Farmers aren't often eager to rewire their farms to facilitate three-phase. Fortunately, they don't have to.

How to Convert from Single to Three-Phase Power Safely and Affordably

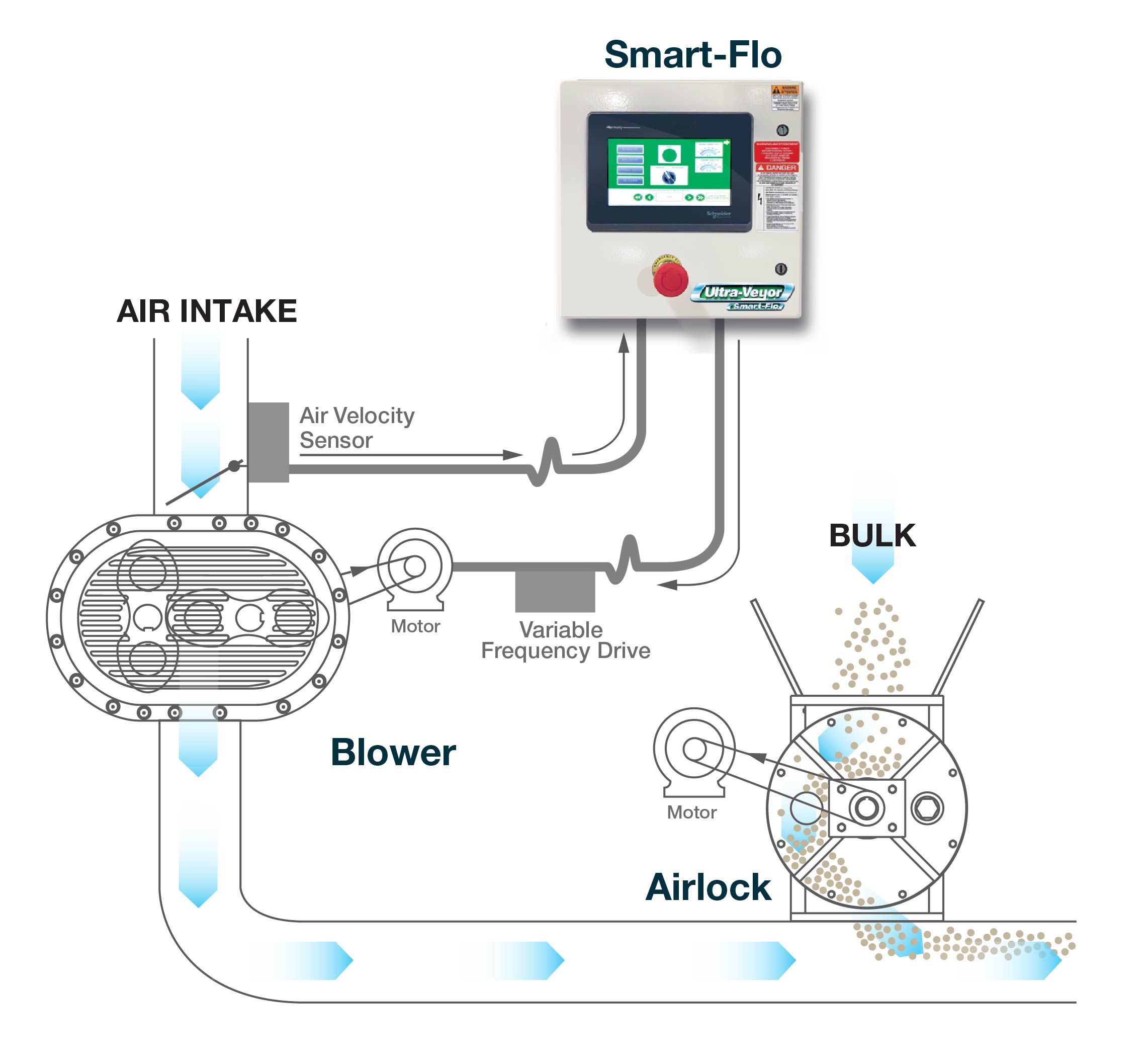

Walinga Blower Systems and AGI NECO and Oakland grain dryers all employ VFD technology. Variable Feed Drives have two outstanding features. First, they allow your motor to slow down and speed up, limiting energy consumption to reduce your power bill.

Walinga's Variable Frequency Drive Systems monitor and automatically adjust motor speeds

Walinga's Variable Frequency Drive Systems monitor and automatically adjust motor speeds

More importantly, they can be set up to draw current from your existing single-phase power source and convert it to three-phase electricity. So, you don't have to change your farm's entire power supply to run one or two bigger machines.

It's worth noting that not every variable frequency drive motor can deliver these results, but AGI, Oakland, and Walinga have engineered their motors with the farmer's single-phase/three-phase dilemma in mind.

Savings and Convenience to Help You Get Growing

There’s a big benefit to this small-scale phase shift. It removes a giant obstacle to building up your bin yard. Instead of waiting until you’ve saved up for a big change, you can increase your grain handling capacity in stages. More high-quality grain in your bin allows you to purchase more components down the road.

Ready to Lower Grain Handling Electricity Costs and Boost Production?

Get in touch with your local Flaman dealer and ask our bin yard experts how you can convert single-phase to three-phase power, add valuable components, and get your bin yard humming.

Posted in Product Information | Tagged with grain handling three phase power walinga neco oakland | More articles by Jeff Brown

Locations

Locations