Flaman Rentals Blog

RSS feed

Categories

Recent activity

- What's it like being a Flaman Rental Dealer?

- A Brief History of the Newest Flaman Store in Swift Current

- Disney's NEW Leadership Excellence Training Course

- Disney's Approach To Quality Service

- Disney's Approach To Quality Service

- Trailering 'Rules of the Road' Updated

- 10th Annual Frank J. Flaman Foundation Gala 2016

- Why Frank Cares

Authors

Archive

Grain Cart Unloading Done Just Right

Posted by Jeff Brown Jun 16, 2022

It really does matter how you look at it. Watching those harvest bushels pour out of your auger may do your heart good, but your back and neck don’t fare so well.

That’s because traditional grain carts unload on the left-hand side, causing you to turn away from your tractor controls. Meanwhile, anyone in your buddy seat has to do his own contortions to stay out of your way while you try to accurately offload grain. All that straining and stretching to see what’s happening makes for a long, unpleasant day - and a sore, sleepless night.

Thankfully, one simple common-sense improvement gives you a clear view of your auger without the aches and pains.

Right-side augers change everything!

J&M Manufacturing’s right-side auger grain cart makes the most of your tractor’s cab layout. Easy access to controls and unobstructed visibility allow you to effortlessly aim your auger right into the semi-trailers. The increased comfort makes grain handling more operator-friendly— with fewer visits to the chiropractor.

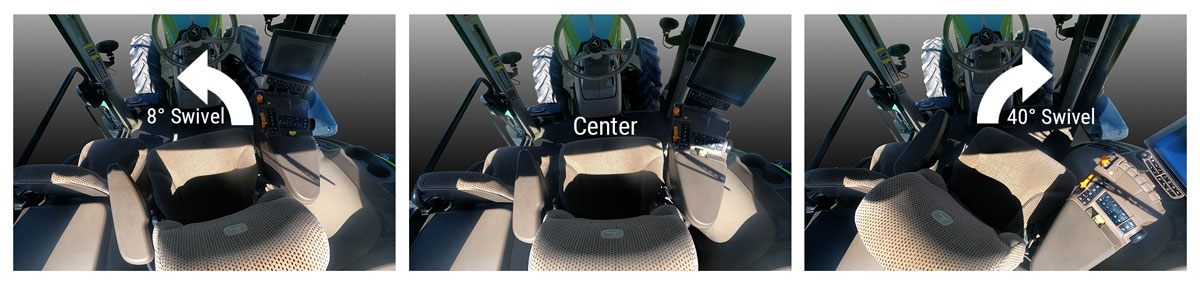

It works with the extended right-hand swivel of most tractor seats and provides a consistently clear view of your controls and monitors. No more groping around, hitting the wrong button, and spilling your valuable grain.

Farmer Approved

Operators have noted the left-to-right change left them less fatigued at the end of the day.

“It's hard to look to your left when your controls are on the right. It’s just a piece of cake.”

Bill Carter, Carter Farms

Different Side. Same Great Quality.

J&M builds their right-side auger model to the same high-quality standards as the rest of their grain cart line. All components and wearable parts remain as durable, dependable, and available as ever. Only the auger position has changed, and it's just one of this cart’s outstanding features.

Speed, Accuracy, and Convenience

The X-tended reach straight auger enables you to transfer 1400 bushels of grain in 2.5 minutes. Meanwhile, J&M’s patented telescoping hydraulic flow control spout sharpens your offloading aim – reducing the amount of grain that spills on the ground.

A 3-position auger system offers a 'storage' position to reduce machine width during transport and parking. The 'field' position limits stress on the auger and keeps the auger clean of any mud. The auger quickly extends to the 'unload' position to drop grain off.

J&M Grain Carts at Flaman

Flaman carries the J&M 1412 grain cart with single 32” wide wheels or a 36” V4 Track to reduce soil compaction. Other heavy-duty standard components include:

- V-Truss axles designed for strength, preventing twisting or bending

- Oversized 6” spindles

- 10-bolt and 20-bolt hubs available

- Computer-balanced bullet auger flighting for quick unload speed and durability

All of our 1412 X-tended reach right-side auger grain carts will be wrapped with special edition Canadian decals, and will feature an iFarm scale, rolling tarp, and 1 ¾" PTO drive.

------

Numbers are limited for 2022. Contact your nearest Flaman Ag expert and reserve your new J&M right-side auger grain cart today!

Posted in New Products | Tagged with J&M grain carts right side auger x-tended reach grain handling harvest | More articles by Jeff Brown

Grain Bag Storage Maintenance Tips

Posted by Calla Simpson Oct 07, 2020

When dealing with a high volume crop, you may decide that short term storage is best to maintain the quality of your harvest. Grain bag storage is a flexible, cost-effective solution for short term storage of bumper yields, provided certain quality control steps are taken. Site preparation, site maintenance, and machine servicing all need to be done properly and timely to ensure your grain holds its quality and value.Below you’ll find tips on the preparation and maintenance steps required to ensure that grain bagging is a successful storage option for your operation.

Site preparation makes for easier maintenance

Selecting the right site for your grain and production is key. It’s best to select a site that is accessible even when the weather is wet, and located in the open to help deter animals. Once an appropriate site has been found, preparing the site is the first step required to set yourself up for easier maintenance.

First, remove any debris such as sticks or sharp objects, then grade the site and ensure the ground is firmly rolled to prevent the grain bags from sinking or water pooling around them. If possible, spray the site with a rodent deterrent to prevent mice and vermin from burrowing under the bags once laid. If proper preparation is not completed, then the bag may not be impervious to air or liquid and can lead to grain spoiling.

Site maintenance once bags are laid and full

The biggest threat to the filled grain bags is animals, especially during the winter months. Snow can create drifts for deer to climb onto the bags, however, using pallets at the ends can deter them. An electric fence, or any sturdy fence, can be used to keep bears and deer away. Year-round, mice pose the biggest risk to the bags as they are known to burrow under, weakening the soil and allowing water to pool, and also chewing through the bag material causing wastage and grain spoilage.

Regular inspections of the bags are needed to ensure no damage from animals, weather, or insects. During wet weather, if the number of mice and vermin are up, then daily bag checks may be required to ensure they stay unharmed. In normal weather conditions, check weekly at a minimum. If there are any punctures, rips, or other damage visible, patching these will prevent moisture from spoiling the grain.

Machine servicing and maintenance

Regular maintenance of Grain Baggers and Grain Extractors helps ensure minimal downtime. Reading and following the manufacturer’s manual is key to keeping these machines in top condition. The manuals describe in detail the following mechanisms and their respective maintenance – the driveline, shear bolts, drive chain tension, and alignment along with the following items needing servicing – fluids and lubricants, auger wear plates, greasing, and servicing intervals. There is also a section on troubleshooting typical issues that can arise such as augers not running, the machine doesn’t move or low unloading capacity.

-----

Discounts available on bulk grain bag orders. For more information, talk to one of our agriculture specialists at your nearest Flaman location.

Posted in Product Information | Tagged with Pro Grain grain bags grain bagging grain baggers grain storage harvest | More articles by Calla Simpson

Beat the Weather with Grain Bagging

Posted by Calla Simpson Sep 11, 2020

The benefits of grain bagging are far and wide, chief among them being the ability to use the weather to your advantage. Since the weather can always turn and change on a dime, it’s important to work around it whenever possible, which is where grain bagging comes in. The airtight, controlled environment inside of a grain bag allows you to store grain and plentiful harvest in a dry space, even when the weather outside is less than ideal. By extending the storage life of your grain, allowing you to store more at once and giving you more flexibility in the way you do so, grain bagging gives people the option to have more options.

Pro Grain Equipment is most passionate about keeping operations running in all weather and situations, saving customers time and money. By grain bagging, you can get your crops off of the field by planning around severe weather to improve efficiency on all sides. The Pro Grain lineup of baggers and extractors work so you can work less, with impressive specs, heavy-duty designs, and improved ease and efficiency for your harvest.

Tip 1: Don’t push the limits of your grain.

Grain bagging allows for safer storage of grain, even during periods of severe weather and freezing temperatures. However, patience is key here. When loading the bags, the weather outside needs to be cool, and the bags should be sealed immediately to ensure that your grain isn’t sitting at a higher temperature than the outside environment. For grain with higher moisture levels, it needs to be dried as soon as possible after the winter season is over. Grain with a lower moisture content can stay in the bags a little bit longer. However, regular temperature monitoring is paramount to making sure that your grain stays in good condition.

Tip 2: Be smart about storage.

Severe weather comes with the territory when farming, and simply when doing anything related to the outside weather. Choosing a storage space that makes sense for your grain is of the utmost importance. When storing grain, look for a place that is highly elevated and away from any sort of drainage that could seep into your bags. You won’t want to store your grain in any manner that could allow natural drainage to affect it, especially during severe storms or periods of melting ice. Before choosing the storage spot for your grain, it should be examined closely to ensure a lack of flooding before severe storms and bad weather. Even though grain bags provide a dry environment for your grain, they can be more susceptible to bad weather — especially if you’re not strategic about placement. You may also want to look into the possibility of grain armor for your grain storage, which gives an extra layer of protection against both weather and wildlife.

Tip 3: Keep a watchful eye on the grain in severe weather.

Grain should be checked periodically, at least once a week, for punctures from severe weather or issues that can arise because of the outside environment. From cosmetic damage that could severely affect the quality of the grain inside to keeping a watchful eye on the temperature of the grain, it’s important to use the weather outside as a gauge for what’s inside your grain bags. By placing the bags in a north to south manner when storing them, the sun will heat the bags evenly for a more consistent environment inside the bags, regardless of the weather.

Tip 4: Be strategic about your timing for a better crop.

One of the biggest benefits of grain bagging is the added ability to increase efficiency by bagging grain right in the field. When you’re expecting severe weather around harvest, grain bagging allows you to control when the crop is loaded into the bags and the condition of the grain. Since grain bagging is a quicker alternative to more traditional means, it allows you to get to your crop before the weather does. Once the grain is in the bag, it’s essentially going to stay the same moisture as when you put it in. By being careful and strategic about your timing, you’ll be able to better store your crop and do so around bad weather.

A Pro Grain bagger in action during Harvest 2019

To learn more about grain bagging and to see which grain bagging products could improve your harvest capabilities, get in touch with us. We would be happy to walk you through everything you require for your grain bagging needs and answer any questions you might have.

-----

Now offering discounted pallet pricing when you buy four or more pallets of grain bags. For more information, talk to one of our agriculture specialists at your nearest Flaman location.

Posted in Product Information | Tagged with Pro Grain grain bags grain bagging grain baggers grain storage harvest | More articles by Calla Simpson

How to Address Farming Challenges with the Right Equipment

Posted by Calla Simpson Aug 20, 2020

With grain bagging at your side, farming challenges won’t loom over your head.

As we begin to enter the new days of the upcoming farming season, there’s one constant: the harvest challenges that will lie ahead. A huge part of being in the farming business is being able to anticipate challenges and to pivot to them, and every good farmer understands that. However, every good farmer also desires to rise above the challenges presented to them, which is where the right equipment and the right mindset come into play.

In the 2019 harvest season, we saw challenges ranging from supply chain management issues and an excess of labour costs to late harvest starts, inclement fall weather, the prediction of lowered storage availability, and an abundance of leftover crops. As the 2020 season begins to come to shape overhead, it’s our job as farmers to think ahead and problem solve the best way we know how.

A great way to pivot and stay on top of things is through the use of grain bags, which have been a huge help to farmers looking for ways to minimize cost along with improving harvest efficiency.

Challenges farmers are facing in 2020

The 2020 harvest season is a unique one as the COVID-19 pandemic hit the globe and affected each and every farm operation. As farmers, the job is always to continue harvesting and providing for others — which can sometimes prove to be a hard thing. As we enter a new season, the issues facing farmers are:

Storage: there is a struggle to find adequate storage space for grain and harvest amid the pandemic.

Supply Chain Issues: stemming from a lowered labour force and leftover grain.

Inventory: confusion in inventory forecasting.

Physical Distancing: the need for physical distancing and increased health measures among labour forces on farms.

How can grain bags help farming challenges?

Flexibility is everything when it comes to farming, whether it be through finding new storage methods or by looking for new ways to cut costs. By using grain bags in your farming operation, you’ll be able to deal with many of the common farm operation challenges that harvesters are facing in 2020.

You’re also able to maximize space and minimizing risk (both financially and personally). The addition of grain bagging equipment and grain bags leads to optimized space on your farm, as well as a lowered need for labour, grain transportation, and grain storage. Here’s how:

Flexible Storage: grain bags allow you to store your harvest directly on your land, completely eliminating the need for extra labour to transport and store grain externally.

Reduced Costs: grain bags simply cost less than other grain storage methods — up to 2/3 less — making them a no-brainer when it comes to downsizing costs in your farming operation.

Increased Productivity: grain bags allow for better time management in your harvesting operation, from less downtime on the combines to more productivity from the workforce at hand.

Harvest Faster: grain bags are helpful when it comes to supply chain issues and excess crops, as they’ll keep your harvest safe from wildlife, spoilage, and weather while you wait.

Increased Efficiency: grain bags help to deal with varied demand, as they offer both efficiency and storage to assist with your needs.

When it comes to challenges, farmers are no stranger to making it work. Farmers are more able to pivot than any other profession in the world, whether it be from weather, cost, or even global pandemics. With grain bags, you’ll be able to take some pressure off of your shoulders when it comes to incoming farming challenges.

-----

Now offering discounted pallet pricing when you buy four or more pallets of grain bags. For more information, talk to one of our agriculture specialists at your nearest Flaman location.

Posted in Ag news | Tagged with Pro Grain grain bags grain bagging grain baggers grain storage harvest | More articles by Calla Simpson

Tips and Resources for a Safe Harvest

Posted by Jennifer Thompson Aug 17, 2020

As harvest begins to start in many parts of Western Canada, Flaman is here to provide the tools and equipment you need to get your crop off quickly and safely. Along with our wide variety of Harvest Helpers to aid you in your work, we’ve collected some important and useful safety tips for harvest time. We want to make sure all our customers return safely from the field and have the resources to support their employees and family members on the farm.

This post will look at 4 main types of safety:

- Grain bin entrapment

- Fire safety and prevention

- Machinery and power lines

- COVID-19 safety

Grain Bin Entrapment

Tough grain is one of the leading causes for producers to enter a bin. Many studies have shown that entering a bin to break up spoiled grain while operating unloading equipment is the leading cause of grain entrapment. A person could become completely covered within 20 seconds. Across Canada, there’s an average of six fatalities every year from grain entrapment or engulfment.

If you need to enter a bin to asses grain, there is a Grain Bin Assessment chart from the Canadian Agricultural Safety Association you can use to assess if it’s safe to enter the bin.

This fact sheet from the Canadian Centre for Health and Safety in Agriculture also has some helpful information about how grain entrapment occurs, as well as preventative and safety measures.

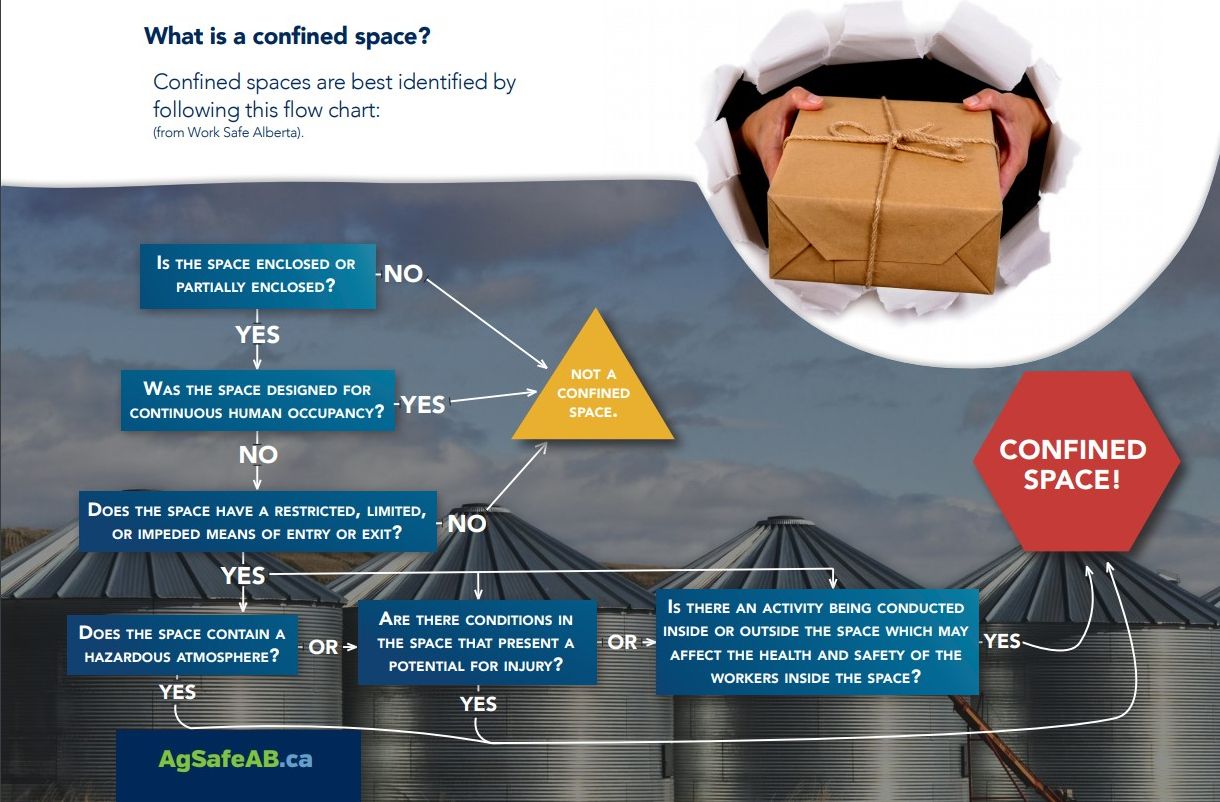

And finally, if you wish to create a Confined Space Management Program for your farm, this quick start guide from Ag Safe Alberta is a useful tool. Along with grain bins, confined spaces also include sumps, wells, feed bins, attics and even some equipment.

Fire Safety and Prevention

Fires in the field can happen all too suddenly when working with dry, flammable material and hot mufflers and electrical wiring. There are some simple pre-cautionary measures you can take to help avoid the risk of injury or loss of equipment due to fire.

- Have working fire extinguishers mounted on equipment, ideally one in the cab and one accessible from the ground. Alberta Agriculture recommends a 10 pound dry chemical, multi-purpose ABC extinguisher and a 2.5 gallon pressurized water extinguisher on combines.

- Remove crop residue, dust, debris, dirt and excess lubricant around all heat sources regularly. Check for a buildup of combustible crop residue around engines and exhaust systems, concealed drive belts and pulleys that can overheat due to friction.

- Be careful when using low clearance vehicles in fields, as exhaust pipes and catalytic converters can ignite dry grass or stubble.

- Check exposed wiring and fuel/hydraulic lines for damage, wear and deterioration.

- Allow engines to cool before refueling.

And for added safety, Flaman carries a variety of firefighting pump and tank units, such as the BE Fire kit or the Fire Skids, to allow you to quickly put out any fires in the field while harvesting.

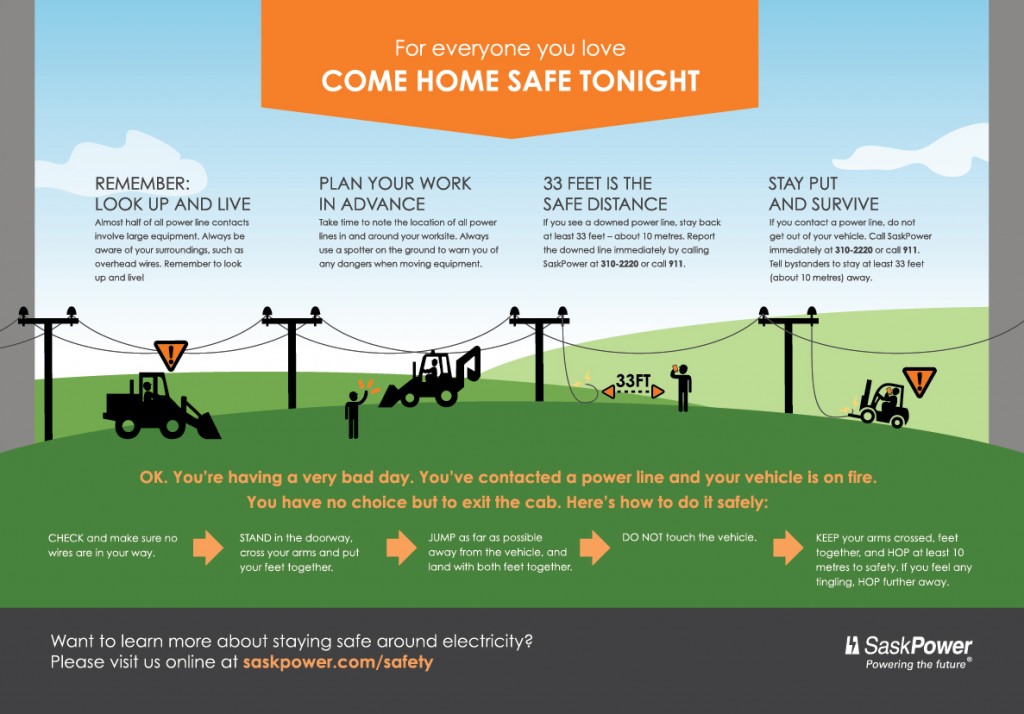

Machinery and Power Lines

Electrical safety is another important area to be aware of when working with large machinery on a farm. More than 40% of agricultural workers in Canada have reported direct hits or near misses with power lines. In 2019, there were 326 farm safety incidents reported to Sask Power. The most common causes of electrocutions on the farm are portable grain augers, large combines, high clearance sprayers and other tall equipment that can come into contact with overhead power lines.

There are two types of electrical injury that can occur:

- Electric shock, when electric current passes through the body causing injury or death.

- Arc flashes: a blast of energy caused by an electric arc, which can produce sounds waves, extreme heat, shrapnel and more, This can lead to lung injuries, ruptured ear drums, burns, blindness or death.

This guide “Electrical Safety on Saskatchewan Farms" from Sask Power talks about potential risks and hazards and offers safety tips, guides and checklists to make sure you and your workers come home safe. Or you can print out this Farm Safety Checklist to make sure everyone knows how to avoid overhead lines and what to do if an accident occurs.

COVID-19 Safety

This year, farming operations will have the added tasks of protecting workers and their family from COVID-19. As an essential service, we recognize that farmers must continue to work to grow our food and feed our country.

Along with the general pre-cautions such as hand washing, physical distancing, cleaning of work attire and wearing gloves, this fact sheet from the Canadian Centre for Occupation Health and Safety offers many safety tips specifically for the agricultural industry in areas such as:

- Transportation

- Sanitation

- Group Living and Residence Recommendations

- Team and Site Management

- And much more.

For those interested in creating an overall safety plan for their operation, this workbook from Ag Safe Alberta lays out the steps to create your own Farm Safe Plan.

Posted in Ag news | Tagged with harvest safety farming grain bins electrical safety | More articles by Jennifer Thompson

The Top 10 Reasons to Use Grain Bags

Posted by Calla Simpson Aug 04, 2020

Grain bagging has been gaining acclaim and popularity among farmers for being a resourceful, flexible, and time and money-saving grain storage option. The benefits are many, and farmers appreciate the efficiency of this innovative storage technique.

If you bag grain, you can expect to experience the following 10 benefits during your harvest season:

1. Saves the farmer's time.

When you bag grain, you reduce time loading grain into trucks and transporting it to grain bins or elevators. You can harvest the grain and store it right there in the field, which drastically cuts down on work time by eliminating so much back and forth to older, more traditional storage containers.

2. Increases harvest efficiency.

Grain bagging is easily the most flexible and efficient method for storing grain. You can store the bags anywhere that’s convenient (field, farm, or other lots), you have unlimited capacity, you have fewer labour constraints, you can move grain faster, and you can segregate grain variety easily into different storage bags. Overall, the processes during harvest are completely streamlined and made as productive as possible with grain bagging.

3. Improves commodity marketing.

Grain bagging preserves grain due to the ideal environment for grain within the bags themselves. When the bags are sealed, they are airtight, which eliminates the need for preservative chemicals and retains the grain quality. If commodity prices are low, and where storage constraints exist, bagging provides flexible unlimited storage. This allows farmers to control and plan the right time to market the crop for top dollar.

4. Reduces labour problems.

Because fewer trucks are required with grain bagging, your labour inefficiencies and costs will naturally reduce. Grain can be stored in the field where it’s bagged, which lowers the need for additional labourers.

5. Provides a storage solution for rented land.

For farmers who rent additional land and either don’t have their own storage bins, don’t have room in storage bins, or don’t want to deal with the cost and inconvenience of using the elevators, grain bagging allows easy storage for those rented land crops. There are virtually endless amounts of storage when you bag your grain.

6. Allows for unlimited storage capacity.

Even if you don’t rent land, if you have a bumper crop, or if your previous year’s crops are taking up storage space, you can utilize grain storage bags to safely and effectively store unlimited amounts of grain directly in the field.

7. Is a cost-efficient storage option.

You can store your grain in bags for about 7 cents per bushel (or less, in some cases). Alternatively, traditional grain bin storage can range anywhere from 14 cents to 37 cents per bushel, a massive expenditure in comparison to grain bagging.

8. Reliable and easily transportable.

After grain bags are sealed, oxygen levels decrease and carbon dioxide increases. This change in the environment can eliminate several strains of fungal diseases and insects without having to use harsh chemicals. Plus, when you are ready to market and sell the crops, you can unload them after harvest when it’s a more convenient time, more labour is available and truck costs are more sensible.

9. Expands the harvest window.

Farmers can start harvest operations earlier in the season and run later into fall by bagging grain that is higher than average moisture. You can unload the grain and dry it at a later time to lower the chance of bottlenecks at a grain dryer.

10. Improves the ability to avoid weather-related harvest issues.

Because your harvest operation will be moving faster and more efficiently, if there are weather delays or setbacks, you’ll be able to easily pivot and adjust your timeline. Your larger window for harvest also allows greater flexibility in dealing with weather restraints.

To learn more about grain bagging and to see which grain bagging products could improve your harvest capabilities, get in touch with us. We would be happy to walk you through everything you require for your grain bagging needs and answer any questions you might have.

-----

Now offering discounted pallet pricing when you buy four or more pallets of grain bags. For more information, talk to one of our agriculture specialists at your nearest Flaman location.

Posted in Product Information | Tagged with Pro Grain grain bags grain bagging grain baggers grain storage harvest | More articles by Calla Simpson

Harvest 2019: An unconventional way to dry your grain in wet conditions

Posted by Paul Boechler Oct 09, 2019

The 2019 harvest is shaping up to be frustrating for most. It’s no secret that harvest is well behind this year, with only 34% of crops being combined in Alberta (47% 3-yr avg), 47% in Saskatchewan (75% 3-yr avg), and 71% in Manitoba (85% 3-yr avg) as of last week. Wet weather has plagued the prairies, with record rainfall in Manitoba and snowfall in southern Alberta & Saskatchewan in September. A combination of high moisture levels and widespread crop damage has contributed to diminished grade.

It’s now a race to get remaining crops off the field and although we can’t control the weather, we can help you maintain the grade of your grain by getting it dried faster and limiting spoilage. The most effective option is a NECO dryer from Flaman, which can be scaled to the size of your operation. However, dryer installs are contingent on many environmental and logistical factors and it’s far from a guarantee that a dryer purchased today would be installed before the end of harvest.

So, what does a farmer do if he or she can’t get a dryer installed in time?

Our team in Saskatchewan has heard a lot of stories from our customers who’ve resorted to unconventional methods to dry their grain. The overwhelming favourite by local farmers has been the Frost Fighter (available only at our Saskatchewan locations), which is a diesel-powered 350,000 BTU industrial heater designed to heat remote construction sites and shops. As it turns out, they are also easily adaptable to a bin aeration system and can pump heat into two bins simultaneously. It’s been a lifeline given the soggy conditions.

Kelly Stewart, the operations manager at our Flaman Moosomin location, was the man who made this idea a reality:

“I saw a video a couple years ago of an Alberta farmer using a similar method and he claimed it worked like a charm. It inspired me to try it out given how wet it’s been this year. Some local farmers put it to work and were extremely pleased with the results. It’s not a perfect solution and we know it’s not recommended by the manufacturers, but desperate times have forced us to think outside the box.

With a little extra work, moving your grain around and monitoring your moisture levels closely, we’ve heard from many happy customers that have seen up to 30,000 BU dried in a week. Obviously, the best way to dry your grain is with a dryer but given how wet it’s been and with more precipitation in the forecast, this has been a great makeshift way to salvage what has been a tough harvest.”

Interested in learning more about grain drying? Talk to one of our agriculture specialists at your nearest Flaman location.

Posted in Ag news | Tagged with grain drying frost fighter neco dryer flaman harvest crops aeration | More articles by Paul Boechler

Locations

Locations