Flaman Rentals Blog

RSS feed

Categories

Recent activity

- What's it like being a Flaman Rental Dealer?

- A Brief History of the Newest Flaman Store in Swift Current

- Disney's NEW Leadership Excellence Training Course

- Disney's Approach To Quality Service

- Disney's Approach To Quality Service

- Trailering 'Rules of the Road' Updated

- 10th Annual Frank J. Flaman Foundation Gala 2016

- Why Frank Cares

Authors

Archive

U-Drain Narrows Down Your Search for Ideal Floor Drainage

Posted by Jeff Brown May 18, 2023

Nothing says, "hope this will last" like cementing something into your floor. Fortunately, U-Drain pre-engineered floor drains were designed by carefully studying what drainage systems should do - and what they've failed to do in the past.U-Drain engineers examined the drawbacks of previous systems and came up with several unique improvements.

- edit low.jpg)

Grate-Free Floor Drainage

Over time grates tend to buckle and bend after being removed and replaced for cleaning, eventually ruining the level, low profile of your floor. U-Drain uses no floor grates. Instead, it replaces them with a slotted design engineered to stay in place for decades of service. There's no need to remove or replace anything.

copy web.jpg)

So Many Options!

U-Drain includes many features to make both homeowners and business operators happy.

Residential and commercial U-Drain installation examples

The slotted surface track is narrow and stays level with your floor, never sticking out from the moment you finish your concrete pour. As a result, homeowners and other property owners can now protect their garage floors, pools, driveways, and walkways without sacrificing style. U-Drain looks good and stays looking good.

Because larger commercial buildings may require more than one drain, U-Drain offers commercial customers several accessories for their specific drainage needs. Commercial packages are built to handle heavy-duty workplace drainage from fire halls to animal shelters. Our team will help you choose the accessories that best suit your unique business needs.

Long Lasting

Unlike other systems that can show up damaged before you even use them, U-drain is made galvanized and stainless-steel construction. The zinc galvanizing process will provide decades of protection against bacteria, rust, and corrosion.

copy web.jpg)

Easy to Install

U-Drain's pre-engineered design makes installation simple. Sections bolt tightly together, lined up perfectly with laser-cut markings. The commercial sections measure 10' in length, unlike the usual 3 to 5' of other drainage systems. That means not only quicker and easier assembly, but also a straighter line going out. Special anchors are welded firmly onto the sections and sump corners, allowing you to secure them directly to your rebar grid.

Structural Integrity

Unlike grate systems that can start buckling from the weight of equipment rolling over them, the slim U-Drain track channels the weight into the surrounding concrete. That's why its residential and commercial safe live load capacity exceeds 10,000 lbs.

Easy to Clean

U-Drain provides a very simple cleaning alternative to removing and replacing grates. A specially designed cleaning paddle inserts easily into your drain slot. You can walk the full length of your drainage slot, sweeping debris into your sump for convenient disposal. Excess water drains out of 4" commercial and 2" residential outlet pipes running from your sump.

Learn More about U-Drain at Flaman

Flaman always takes pride in giving our customers one less thing to worry about, so we'll be happy to talk with you about how a U-Drain system can help make your home, workshop, or business tidier and more productive. We'll have your coffee and plenty of advice on options, benefits, and installation.

You can find U-Drain at any of the 11 Flaman dealerships across the prairies. In Alberta, you can find us in Nisku (just south of Edmonton), Lethbridge, Medicine Hat, and Fairview. Saskatchewan has six locations: Moosomin, Prince Albert, Saskatoon, Southey, Swift Current, and Yorkton. We also serve Manitoba, through our Swan River location.

Posted in Product Information | Tagged with U-drain floor drain drainage systems | More articles by Jeff Brown

AGI Batco UCX3 Conveyor. U-Trough Convenience. All Commodities.

Posted by Jeff Brown May 08, 2023

We could speak volumes about the volumes the all-commodity AGI Batco UCX3 U-Trough Belt Conveyor can process. It’s powerful, high-capacity, and fast. In ideal conditions, it can move up to 12,500 bushels (about 340 tons) of canola in a single hour.

At that rate, it’s not sheer fantasy to imagine loading a Super B in 10 minutes. Even heavier crops like wheat and peas still whistle through at about 10,000 BPH.

Fast as that ride might be, the cereals, pulses, oilseeds, or fertilizers you put through it come out hardly the worse for wear. Gentle handling is the beauty of a U-trough system – especially one with the UCX3’s problem-solving design. It focuses on eliminating points where spillage, crushing, and other damage can occur, from intake to spout.

Advanced Leakage Protection

That starts with the redesigned collapsible hopper. It’s built low, so you can be sure it will fit easily under any bin. The new, reinforced design also maximizes grain flow by minimizing potential leakage and grinding along its sides.

A double-lip sealed edge keeps your commodities tightly in place as they travel up the conveyor’s 15” Direct X belt. It’s a U-trough-ready update of the chevron pattern used in the successful AGI Batco BCX3 tube conveyor.

Sticking With What Works

The BCX3 design worked so well that many of its features have been incorporated into, or adapted to, the UCX3. These include:

Turbo clean wash system, two belt scrapers, and belt brush. Working together in one remarkably easy clean-out process, they keep your belt debris-free and oilseed-friendly.

Redesigned S-Drive. Easily adjusted with normal tools, this feature keeps your belt running straight and true without the risk of overtightening your pinch-roller bearings.

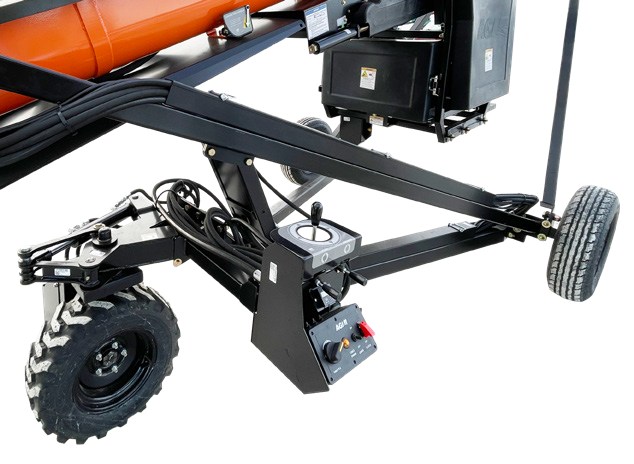

IBEX Mover Kit. Redesigned with a built-in braking system and a 160° turning radius, the IBEX is powerful and easy to maneuver whether you’re on a flat, dry surface or navigating deep muck. Two features provide the outstanding traction you’ll need to get you through a rain or snow-drenched day in your bin yard: Skid steer-style tires for better traction and single-wheel drop-and-go convenience and balance.

More Power to U.

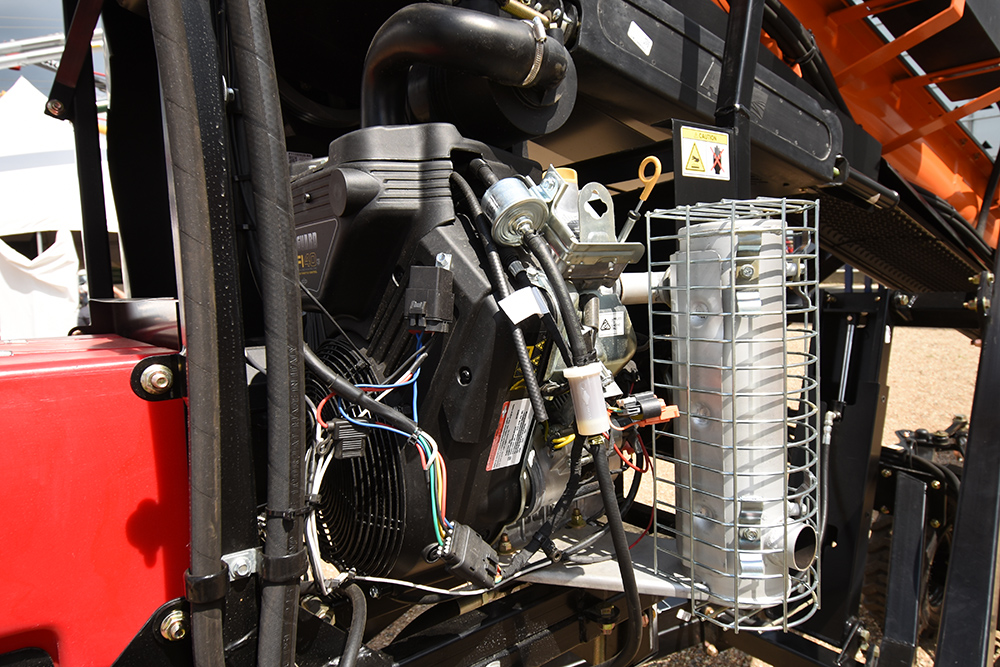

One notable difference between the U-Trough Conveyor and the BCX3 is the size of their engines. The BCX3 offers a choice of two gasoline engines – the 32HP Kohler or the 33HP EFI Vanguard. The UCX3 bumps the power up with a 40HP EFI Vanguard motor and upgraded drive components to further increase hydraulic performance and longevity.

Learn what the UCX3 can do for you at Flaman.

Want to know more about the AGI Batco UCX3 U-Trough Conveyor? You can find expert advice at 11 Flaman dealers across Manitoba, Saskatchewan, and Alberta. Drop by your nearest Flaman location and get an up-close look at features like the ergonomic command centre, IBEX Mover Kit, and spillage control.

Ask our knowledgeable sales staff how the UCX3 or any of our other equipment can help your farming operation.

Posted in Product Information | Tagged with agi batco u-trough conveyor belt oilseed | More articles by Jeff Brown

What's it like being a Flaman Rental Dealer?

Posted by Jeff Brown Jan 17, 2023

We could explain how we support our dealers and how our Rentals division reflects Flaman’s history and community culture (which we will). However, to provide a clear picture of the actual dealership experience, it’s best to let our dealers speak for themselves.

Today, we are sharing the experience of current rental dealers with you.

An Unforeseen Advantage: Brian Headon

We recently talked with Brian from Headon Rentals in Lloydminster. He shared his insightful perspective on how becoming a Flaman dealer added to their existing livestock farm.

We decided to become a Flaman Rental Dealer because it complements our farm. We have a year-round livestock operation and don’t have the same seasonal demands as grain producers. Flaman Rentals just made sense as a cash-flow business. Now that rental income has morphed into its own enterprise in the 11 years since we’ve partnered with Flaman.

There’s an unforeseen advantage in creating this massive relationship with the community. You really don’t know what other producers are doing. We sort of became this hub, and we get to see how innovative other growers have become.

Our success in the first year happened because of the early support from Flaman Rentals. Whenever we had a question or concern, we could count on Flaman, and the local farming community could count on us.

—Brian Headon, Headon Rentals, Lloydminster, AB.

The Roots of Flaman Rentals

The national company you now know as Flaman began in 1959 with Frank Flaman and a baler and swather. You could say that custom baling and harvesting in the Southey, Sask area was Frank’s first rental venture. The commodities were his equipment and his manpower. This was the seed that would grow to become Flaman Rentals in 1993. It was nurtured by Frank’s desire to reduce the financial pressure on farmers and help make a difference in his community.

Over 80 Flaman Dealerships exist across Western Canada and the U.S., supported by management, administrative, IT and marketing teams in our head office. We’ve expanded the range of products offered by our rental services to meet our client’s ever-changing needs. Even though many things have changed, one thing that remains the same is Flaman’s commitment to the customer.

With the success of our existing Flaman Rental dealers, we expect to see many new ones sprout up. Many people share our vision of making a difference by helping local farmers succeed in today’s climate.

The greatest thing about being a Flaman Dealer: Chad Cissell

Chad Cissell of Darkside Rentals shares a story similar to Brian’s. He took over an existing Flaman dealer five years ago.

Flaman support was top-notch as we were first getting started. And even through the years, if you have a question, our Territory Manager will have an answer. We are one of the larger dealers with loads of experience, and we pass on our expertise to other Flaman Dealers.

We serve lots of smaller farms that can’t just buy high-dollar equipment – ones that need quality implements in the short term to remain competitive. We offer that option at a fraction of the cost.

Being part of the dealer network is the greatest thing about being a Flaman Dealer. We share tips and tricks, stories from the field, and help each other grow. There is still that competitive spirit amongst the dealers but… it just makes everyone better. That network is valuable.

For those considering becoming a dealer, it’s very different day to day. Especially when you’re working with 100-plus customers over the year. You're used to seeing them at the grain market or auction house on occasion. It’s different when you become hands-on with them and understand what they need.

Being a Flaman Rental Dealer is a challenging experience and I enjoy every minute of it!

—Chad Cassel, Darkside Rentals, Ponoka, AB.

Big Commitment. Ample Rewards.

As you can see, a lot goes into becoming a Flaman Rental Dealer, but it comes with ample rewards. If you operate a farm or an agriculture-related business like delivering fuel or fertilizer, it's a great way to supplement your income. Dealership candidates with a solid understanding of the needs of farmers, farming communities, and agri-business go to the front of the line. We look for people like Brian and Chad who realize that maintaining that level of involvement is a reward.

At Flaman, we pride ourselves on being supportive; If you think you’re the kind of person who’d enjoy this kind of opportunity, join our team, you can count on our help finding the right equipment for your location. Flaman helps you succeed so you can continue to be the center of the community - meeting everyone in the surrounding area and being part of an invaluable and coherent dealer network.

If you are interested in joining this mutually supportive network of dealers, We invite you to learn more about the Flaman Rental opportunity.

Posted in Testimonials | Tagged with Rentals Ag news | More articles by Jeff Brown

6 Reasons to Use a Riteway 7-Bar Harrow This Year

Posted by Mitch Flaman May 06, 2022

When it’s time to get your fields prepped for seeding, there are a few different equipment options to choose from.

For many years, harrows have been used to prepare fields in different capacities. Whether you are levelling off ruts, busting up hardpan, or removing trash before seeding, both the Riteway 5-bar and 7-bar harrows have a specific purpose in the tillage cycle. With low-till or zero-tillage farming practices gaining popularity in the last decade, you need a way to create ideal seedbeds for your crop.

Riteway 5-Bar Heavy Harrow in use

Heavy harrows, often known as 5-bar harrows, are very common and do a great job moving dirt, even in wet conditions. The Riteway 7-bar harrow is lighter than a traditional heavy harrow and has twice as many tines, offering you the flexibility you need to deal with excess straw post-harvest and residue management before seeding.

.jpg)

Riteway 7-Bar Harrow

We put together six reasons why you should consider using a Riteway 7-bar harrow this year.

1. Trash and Residue Removal

“At its most basic point: if you’re looking to move soil – stick with your 5-bar, but if you’re looking for trash management there’s no better way to go than the 7-bar harrow.”

Brad Grass, Territory Sales Manager at Riteway Manufacturing

Think about how you use a large fan rake to clean up all the leaves in the fall. You go over the surface of your lawn, gently collecting the leaves and removing them. When using a garden rake, you collect everything from the roots of your grass – eliminating everything that protects the soil.

7-bar harrows work much the same as a large leaf rake, cleaning up and breaking down straw residue, while leaving the soil mildly agitated. Featuring twice as many tines as a heavy harrow, the 7-bar’s ½” tines provide better agitation as the harrow floats over the field – allowing for greater trash removal and distribution.

.jpg) 24" long 1/2" tines on the Riteway 7-Bar Harrow

24" long 1/2" tines on the Riteway 7-Bar Harrow

2. Moisture Retention

The smaller diameter tines on the 7-bar harrow provide greater agitation while disturbing less ground. By only mixing up the top layer of the soil, it allows the moisture to stay in the ground. The goal is to remove extra trash on the surface, not dry out the soil.

3. Less Soil Compaction

The 82’ Riteway 7-bar harrow weighs 19,900 lbs and is the heaviest and strongest 7-bar in its class. Despite its weight, the 7-bar won’t compact the soil down as much as a heavy harrow because it floats over the topsoil instead of digging down. Less compaction, combined with better moisture retention, creates a better environment for plant development.

Riteway 7-Bar Harrow in use

4. Seed Bed Prep

Remove all the trash and debris left from harvest and prepare your seedbeds without removing soil. This allows the seed drills to move easily through the field with less straw build-up around the knife. After using a 7-bar harrow, you’ll end up with a nice, clean surface for a fresh start in the spring.

Riteway 7-Bar Harrow field demo

5. Herbicide Application

As some weeds become resistant to certain herbicides, older chemicals are making a comeback. Because granular herbicide mixes well with topsoil, the 7-bar harrow can effectively protect your crops from invasive weeds. The 7-bar helps introduce the granular chemical into the soil just enough so that it can be evenly distributed throughout the field.

6. Mechanical Weed Removal

The 7-bar’s lightweight spring tines help manage weeds that start to thrive in your field after harvest. By damaging these weeds enough so they stop growing, your crops have less competition for nutrients in the soil.

.jpg) Spring Pressure Kit on the Riteway 7-Bar Harrow

Spring Pressure Kit on the Riteway 7-Bar Harrow

As you can see, there are many advantages to using a Riteway 7-bar harrow to prepare your fields for seeding and manage the crop residue after harvest.

Brad, Riteway Manufacturing, walks through the features on the 7-Bar Harrow

------

If you have any questions about our Riteway 7-Bar, Heavy, or Rotary Harrows, or any of our other tillage equipment, contact us or visit your nearest Flaman location.

Posted in Product Information | Tagged with Riteway harrow 7-bar heavy harrow tillage field prep seeding | More articles by Mitch Flaman

Increase efficiency & reduce downtime during spraying this year

Posted by Mitch Flaman Mar 05, 2021

What started in the fall of 2020 as an idea to build an innovative sprayer trailer designed with functionality and convenience at the top of mind has resulted in the ST series of agriculture sprayer tender trailers from Flaman.

Model ST-9100

With safety, speed, and ease of use as the three pillars of design, these trailers were created to efficiently mix different batches of chemicals and quickly fill your sprayer – all with minimal downtime.

Now that all the planning and engineering has been completed, we are excited to have these units rolling through our production lines and hitting the market for the spring 2021 and 2022 seasons.

“We listened to our customers and put together all their best ideas into these all-new, all-encompassing sprayer tailers. Giving the customer all the features that they have always wanted to have – all in one unit. Flaman is proud to bring this product offering out to the marketplace just in time for the busy spring farming season.”

Bret Watson, Engineer

The Flaman ST-9100 and ST-9200 are tender-style trailers, built around a 53’ Behnke tri-axle trailer with a heavy-duty air ride suspension and 22.5” tires. They have an 80,000 lb GVWR, cross members on 12” centres, powder-coated paint, and Apitong hardwood decking. These trailers feature a 48” heavy-duty undermount toolbox for additional storage, mud flaps, and dual 2-speed jacks. The most notable difference of the ST-9100 and ST-9200 from other units on the market is the custom-designed 11’ upper kick compared to traditional 10’ upper kicks. This allows for a heavy-duty, low-profile 3,200 US gallon tank to clamp securely to the top deck with heavy-duty deck pins.

Chem Handler III

These ag sprayer trailers are completely outfitted with 3” hose and pipe for speed when filling and emptying the 4,500 US gallon (17,000L) tank on the back and the 3,200 US gallon (8300L) tank on the front. They are fastened directly to the trailer deck with heavy-duty steel mounting pins for safety instead of ratchet straps or chains. The entire system is controlled and mixed with a heavy-duty 3” Chem Handler III, a chemical handler that is fast, safe, and easy to use. The 3” steel piping is mounted under the trailer to keep the deck clean and eliminate the potential for tripping. The fill station is versatile and can feed either each tank individually or at the same time.

Features that make the ST-9100 and ST-9200 stand out include:

Stowable Fill Arm

The stowable fill arm has been engineered with 5” HSS tubing to manage the hose when filling the sprayer. This versatile fill arm takes care of the weight of the 3” hose when it’s full of product, and it swings out when filling the sprayer and easily folds back in when you are done. Your back will thank you!

The stowable stairs give safe and easy access to the deck when managing the Chem Handler III. In a matter of seconds, the safety pins can be pulled out and the stairs can be folded down – no more hopping up and down from the deck like you are training for a Spartan Race! The textured grate steps provide additional traction and reduce the potential for unnecessary slips and falls.

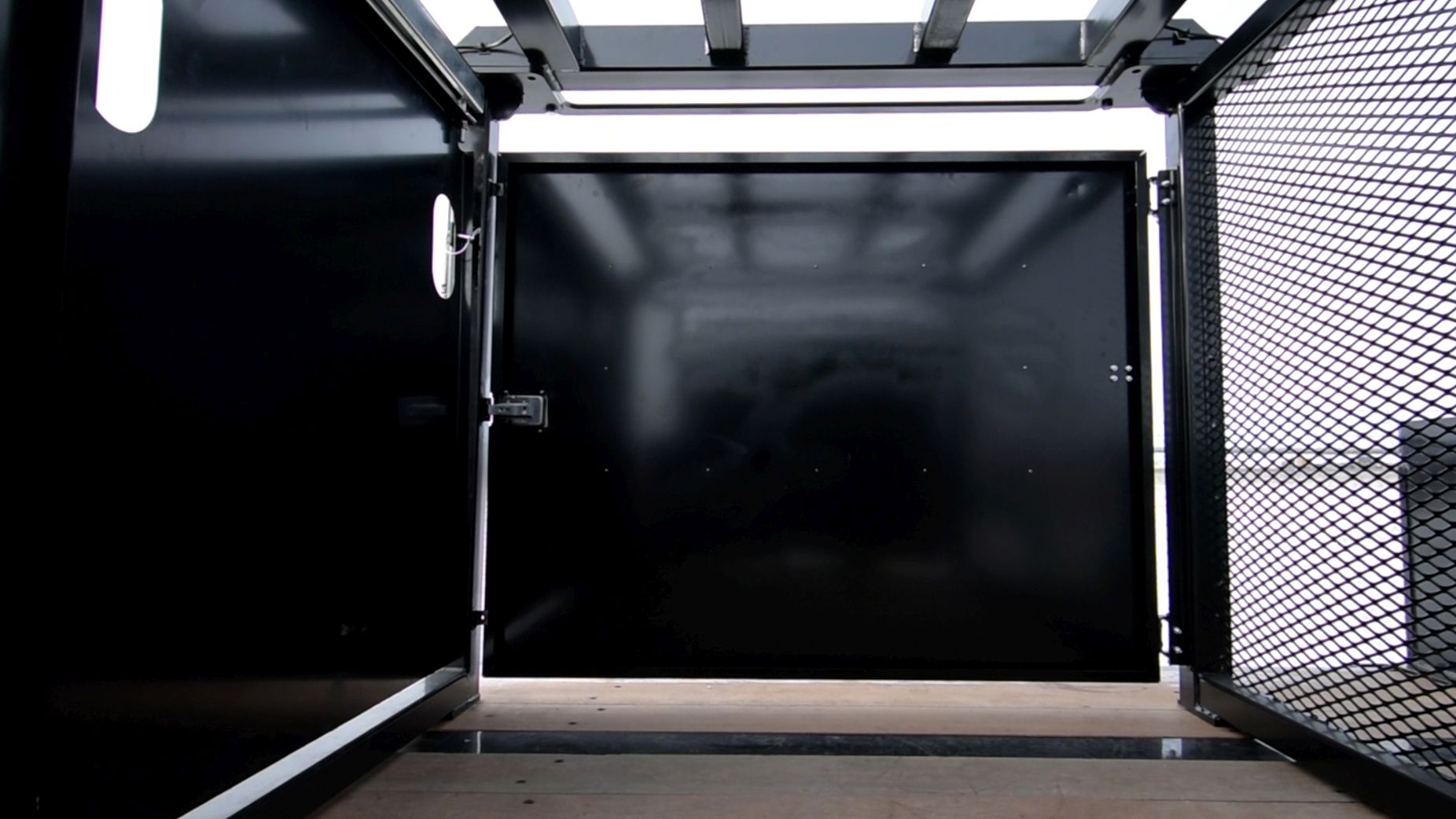

The tote storage is loaded with innovative features and has been engineered to safely store two chemical totes on top with secure ratchet strap tie-downs. It is easily accessible from both sides of the trailer, as well as from on top of the deck. It can be used to store extra fuel, additional hose and couplings, chemical jugs and treatments, tools, extra parts or sprayer nozzles, and safety equipment. It has strategically been offset towards the passenger side of the trailer to allow for additional walking room on the driver side and access the upper kick with an integrated safety handrail.

Both tanks have built-in sight tubes for easy water level readings.

LED Light Kit

The trailer comes standard with four LED lights to increase safety and reduce the chances of an accident after the sun goes down. There is a convenient light switch located on the passenger side of the tote cage and in easy reach from the ground or deck. All wires are run inside of the frame and are powered by the 7-pin trailer plug.

The ST-9200 includes an additional 1680-gallon (6400L) Chembine Hot Tank. Designed to reduce wait times and increase efficiency, the Hot Tank can mix and agitate the next batch of treatment while the sprayer is out in the field. When the sprayer is ready for another fill, the Hot Tank can quickly unload the next batch of chemicals that have already been already prepared. This feature can be added to any ST-9100.

-----

For more information on the Flaman ST Series Sprayer Trailers, talk to one our ag & trailer specialists at your nearest Flaman location.

Posted in New Products | Tagged with spraying sprayer trailer ag trailer Flaman ST-9100 ST-9200 | More articles by Mitch Flaman

After 50 years, Kello-Bilt discs remain innovative, family-manufactured, and built to stand up

Posted by Mitch Flaman Feb 03, 2021

When buying a field disc, you need the confidence to know that it is going to work the way you expect when you need it and not break down, leaving you stranded with work to be done. This is why Flaman chose to team up with Kello-Bilt products over 40 years ago. Like Flaman, Kello-Bilt remains a family-owned business that keeps quality and reputation top of mind. A field disc is meant to be put through tough conditions. Continued innovation is what has kept Kello-Bilt tillage equipment ahead of the curve and outlasting its competitors.

Kello-Bilt Tandem Disc - Model 225TSW

For over 50 years, Kello-Bilt discs have been Canadian-made to “be better”. They’re built heavy and designed to last in the toughest conditions. The company has continued to evolve with experience and improve the things that “didn’t work” or simply didn’t stand up to other discs in the tough Canadian environment. This is how the idea for the self-lubricating oil-bath bearing was born. The self-lubricating oil-bath bearing proved to be superior to traditional greaseable ball bearings.

Today, regardless of price, Kello-Bilt discs are still manufactured to the highest standard with Canadian and North American steel. They are constructed with high-strength steel tubing, heavy gussets, and powder-coated components to ensure best-in-class quality and performance. This ensures the longevity of your purchase for years to come. The oil-bath bearings and boron steel blades are designed and sourced from Brazil and Argentina specifically for Kello-Bilt. Boron steel blades are less brittle than traditional carbon steel blades.

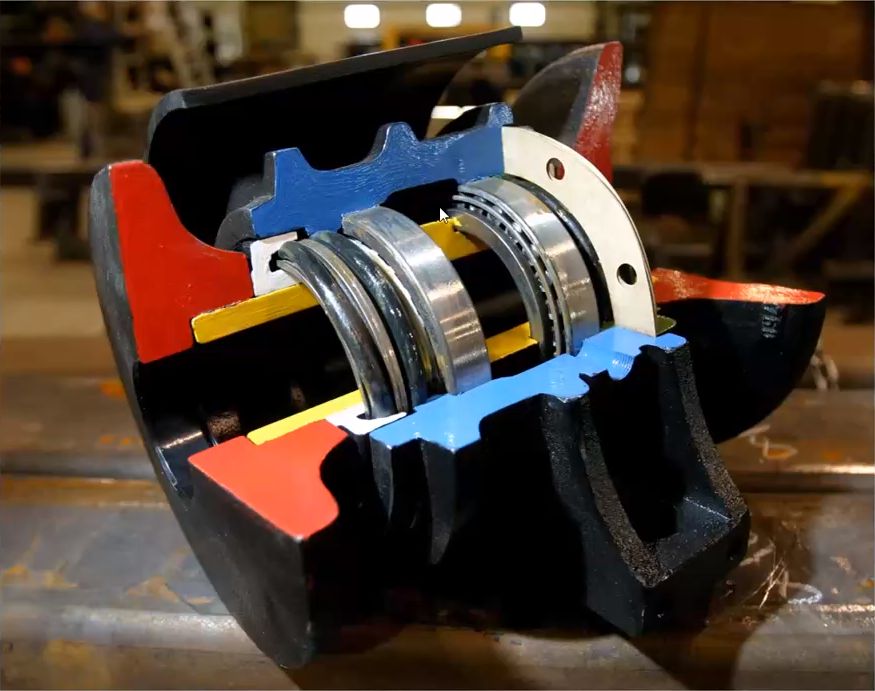

Oil-Bath Bearing Interior

Oil-Bath Bearing InteriorThe oil-bath bearing uses two tapered roller bearings mounted in a cast housing. The dual-cone seal constantly lubricates the bearing. They sit on the interior axle, which is never in contact with the actual gang shaft. Tapered roller bearings are ideal for a disc application because they are designed for side thrust. Most of the pressure a disc blade faces is side pressure, NOT radial pressure. Ball bearings are designed for radial pressure. Oil-bath bearings are extremely low maintenance. Testimonials show Kello-Bilt discs from the 1980s are still operating with their original bearings after over five or more sets of replacement blades. The beauty of the oil-bath bearing is that they’re rebuildable. As long as you make sure not to run the blades too loose, as it will put pressure on the housing and cause leakage, the bearings can last for decades.

Kello-Bilt Offset Disc - Model 275

If you’re serious about purchasing a quality field disc, contact your local Flaman dealer today. A Kello-Bilt disc with oil-bath bearings might be as serious as you are.

Posted in New Products | Tagged with Kello-Bilt disc field disc tillage | More articles by Mitch Flaman

Grain Bag Storage Maintenance Tips

Posted by Calla Simpson Oct 07, 2020

When dealing with a high volume crop, you may decide that short term storage is best to maintain the quality of your harvest. Grain bag storage is a flexible, cost-effective solution for short term storage of bumper yields, provided certain quality control steps are taken. Site preparation, site maintenance, and machine servicing all need to be done properly and timely to ensure your grain holds its quality and value.Below you’ll find tips on the preparation and maintenance steps required to ensure that grain bagging is a successful storage option for your operation.

Site preparation makes for easier maintenance

Selecting the right site for your grain and production is key. It’s best to select a site that is accessible even when the weather is wet, and located in the open to help deter animals. Once an appropriate site has been found, preparing the site is the first step required to set yourself up for easier maintenance.

First, remove any debris such as sticks or sharp objects, then grade the site and ensure the ground is firmly rolled to prevent the grain bags from sinking or water pooling around them. If possible, spray the site with a rodent deterrent to prevent mice and vermin from burrowing under the bags once laid. If proper preparation is not completed, then the bag may not be impervious to air or liquid and can lead to grain spoiling.

Site maintenance once bags are laid and full

The biggest threat to the filled grain bags is animals, especially during the winter months. Snow can create drifts for deer to climb onto the bags, however, using pallets at the ends can deter them. An electric fence, or any sturdy fence, can be used to keep bears and deer away. Year-round, mice pose the biggest risk to the bags as they are known to burrow under, weakening the soil and allowing water to pool, and also chewing through the bag material causing wastage and grain spoilage.

Regular inspections of the bags are needed to ensure no damage from animals, weather, or insects. During wet weather, if the number of mice and vermin are up, then daily bag checks may be required to ensure they stay unharmed. In normal weather conditions, check weekly at a minimum. If there are any punctures, rips, or other damage visible, patching these will prevent moisture from spoiling the grain.

Machine servicing and maintenance

Regular maintenance of Grain Baggers and Grain Extractors helps ensure minimal downtime. Reading and following the manufacturer’s manual is key to keeping these machines in top condition. The manuals describe in detail the following mechanisms and their respective maintenance – the driveline, shear bolts, drive chain tension, and alignment along with the following items needing servicing – fluids and lubricants, auger wear plates, greasing, and servicing intervals. There is also a section on troubleshooting typical issues that can arise such as augers not running, the machine doesn’t move or low unloading capacity.

-----

Discounts available on bulk grain bag orders. For more information, talk to one of our agriculture specialists at your nearest Flaman location.

Posted in Product Information | Tagged with Pro Grain grain bags grain bagging grain baggers grain storage harvest | More articles by Calla Simpson

Move your grain with the all-new AGI Hutchinson Double Run Chain Conveyor

Posted by Paul Boechler Sep 14, 2020

The AGI Hutchinson Double Run Chain Conveyor is a brand new product to the Flaman lineup. It is built in Western Canada with the prairie farmer in mind. Manufactured at AGI’s plant in Swift Current, SK, it is designed to handle delicate crops grown on the prairies, like pulses, far more gently than an auger would.

The UHMW plastic paddles gently convey grain

Maneuverable in Tight Spaces:

Modeled after the clean grain elevator on your combine, its UHMW plastic paddles convey crops to your bin in a gentle manner. A huge benefit of this is the ability to operate at full capacity from nearly any angle, fitting into tighter spaces.

Another feature of the Double Run is the easy to use swivel arc kit, which makes the unit highly portable around the yard. You can move it from bin to bin or dryer, by simply swapping a few pins.

The swivel arc kit allows for easy maneuverability

Low Power Requirements:

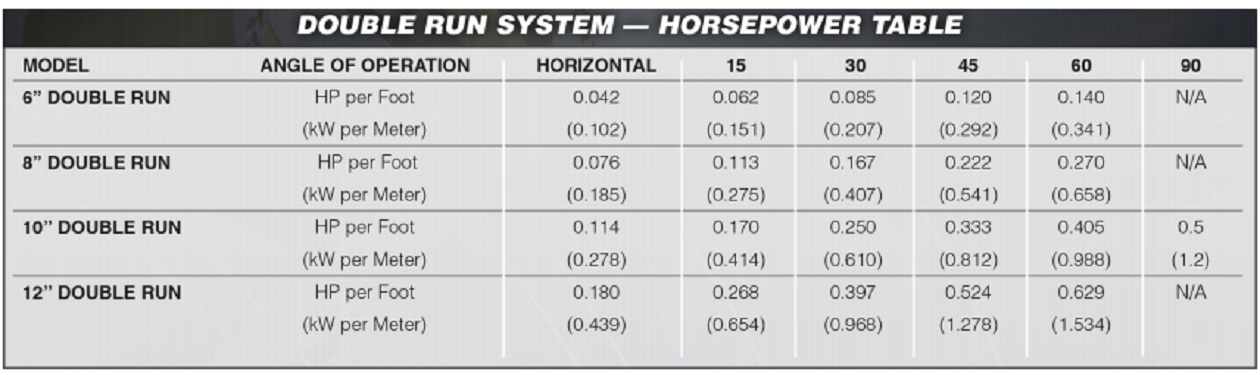

While the Double Run is powerful in getting your grain into the bin, it has a low horsepower requirement compared to alternative grain handling equipment. As an example, 8” model with a length of 82’ requires just 18 HP at a 45° angle (see chart below). These units are available with an electric motor or PTO drive, giving you plenty of power options.

Proven Reliability & Longevity:

We all know an unreliable auger can be a huge problem for your operation at harvest time. The Double Run was designed as a solution to this problem. The chain conveyor requires less maintenance and has more longevity than your typical auger. Keep the chain running straight and tensioned properly, and these units will just run. And run. And run.

Travis Frey of AGI walks us through exactly what makes this unit different:

The Double run comes in lengths of up to 82’ on the 8” and 10” models, with up to 4,000 BPH capacity on the 8” and 6,000 BPH on the 10”. It is also available in a 12” model, which has a 10,000 BPH capacity and lengths up to 130’.

Stop by your local Flaman Ag store or give us a call for more information on this unit.

Posted in New Products | Tagged with AGI Hutchinson Double Run chain conveyor grain handling grain systems Flaman | More articles by Paul Boechler

Beat the Weather with Grain Bagging

Posted by Calla Simpson Sep 11, 2020

The benefits of grain bagging are far and wide, chief among them being the ability to use the weather to your advantage. Since the weather can always turn and change on a dime, it’s important to work around it whenever possible, which is where grain bagging comes in. The airtight, controlled environment inside of a grain bag allows you to store grain and plentiful harvest in a dry space, even when the weather outside is less than ideal. By extending the storage life of your grain, allowing you to store more at once and giving you more flexibility in the way you do so, grain bagging gives people the option to have more options.

Pro Grain Equipment is most passionate about keeping operations running in all weather and situations, saving customers time and money. By grain bagging, you can get your crops off of the field by planning around severe weather to improve efficiency on all sides. The Pro Grain lineup of baggers and extractors work so you can work less, with impressive specs, heavy-duty designs, and improved ease and efficiency for your harvest.

Tip 1: Don’t push the limits of your grain.

Grain bagging allows for safer storage of grain, even during periods of severe weather and freezing temperatures. However, patience is key here. When loading the bags, the weather outside needs to be cool, and the bags should be sealed immediately to ensure that your grain isn’t sitting at a higher temperature than the outside environment. For grain with higher moisture levels, it needs to be dried as soon as possible after the winter season is over. Grain with a lower moisture content can stay in the bags a little bit longer. However, regular temperature monitoring is paramount to making sure that your grain stays in good condition.

Tip 2: Be smart about storage.

Severe weather comes with the territory when farming, and simply when doing anything related to the outside weather. Choosing a storage space that makes sense for your grain is of the utmost importance. When storing grain, look for a place that is highly elevated and away from any sort of drainage that could seep into your bags. You won’t want to store your grain in any manner that could allow natural drainage to affect it, especially during severe storms or periods of melting ice. Before choosing the storage spot for your grain, it should be examined closely to ensure a lack of flooding before severe storms and bad weather. Even though grain bags provide a dry environment for your grain, they can be more susceptible to bad weather — especially if you’re not strategic about placement. You may also want to look into the possibility of grain armor for your grain storage, which gives an extra layer of protection against both weather and wildlife.

Tip 3: Keep a watchful eye on the grain in severe weather.

Grain should be checked periodically, at least once a week, for punctures from severe weather or issues that can arise because of the outside environment. From cosmetic damage that could severely affect the quality of the grain inside to keeping a watchful eye on the temperature of the grain, it’s important to use the weather outside as a gauge for what’s inside your grain bags. By placing the bags in a north to south manner when storing them, the sun will heat the bags evenly for a more consistent environment inside the bags, regardless of the weather.

Tip 4: Be strategic about your timing for a better crop.

One of the biggest benefits of grain bagging is the added ability to increase efficiency by bagging grain right in the field. When you’re expecting severe weather around harvest, grain bagging allows you to control when the crop is loaded into the bags and the condition of the grain. Since grain bagging is a quicker alternative to more traditional means, it allows you to get to your crop before the weather does. Once the grain is in the bag, it’s essentially going to stay the same moisture as when you put it in. By being careful and strategic about your timing, you’ll be able to better store your crop and do so around bad weather.

A Pro Grain bagger in action during Harvest 2019

To learn more about grain bagging and to see which grain bagging products could improve your harvest capabilities, get in touch with us. We would be happy to walk you through everything you require for your grain bagging needs and answer any questions you might have.

-----

Now offering discounted pallet pricing when you buy four or more pallets of grain bags. For more information, talk to one of our agriculture specialists at your nearest Flaman location.

Posted in Product Information | Tagged with Pro Grain grain bags grain bagging grain baggers grain storage harvest | More articles by Calla Simpson

How to Address Farming Challenges with the Right Equipment

Posted by Calla Simpson Aug 20, 2020

With grain bagging at your side, farming challenges won’t loom over your head.

As we begin to enter the new days of the upcoming farming season, there’s one constant: the harvest challenges that will lie ahead. A huge part of being in the farming business is being able to anticipate challenges and to pivot to them, and every good farmer understands that. However, every good farmer also desires to rise above the challenges presented to them, which is where the right equipment and the right mindset come into play.

In the 2019 harvest season, we saw challenges ranging from supply chain management issues and an excess of labour costs to late harvest starts, inclement fall weather, the prediction of lowered storage availability, and an abundance of leftover crops. As the 2020 season begins to come to shape overhead, it’s our job as farmers to think ahead and problem solve the best way we know how.

A great way to pivot and stay on top of things is through the use of grain bags, which have been a huge help to farmers looking for ways to minimize cost along with improving harvest efficiency.

Challenges farmers are facing in 2020

The 2020 harvest season is a unique one as the COVID-19 pandemic hit the globe and affected each and every farm operation. As farmers, the job is always to continue harvesting and providing for others — which can sometimes prove to be a hard thing. As we enter a new season, the issues facing farmers are:

Storage: there is a struggle to find adequate storage space for grain and harvest amid the pandemic.

Supply Chain Issues: stemming from a lowered labour force and leftover grain.

Inventory: confusion in inventory forecasting.

Physical Distancing: the need for physical distancing and increased health measures among labour forces on farms.

How can grain bags help farming challenges?

Flexibility is everything when it comes to farming, whether it be through finding new storage methods or by looking for new ways to cut costs. By using grain bags in your farming operation, you’ll be able to deal with many of the common farm operation challenges that harvesters are facing in 2020.

You’re also able to maximize space and minimizing risk (both financially and personally). The addition of grain bagging equipment and grain bags leads to optimized space on your farm, as well as a lowered need for labour, grain transportation, and grain storage. Here’s how:

Flexible Storage: grain bags allow you to store your harvest directly on your land, completely eliminating the need for extra labour to transport and store grain externally.

Reduced Costs: grain bags simply cost less than other grain storage methods — up to 2/3 less — making them a no-brainer when it comes to downsizing costs in your farming operation.

Increased Productivity: grain bags allow for better time management in your harvesting operation, from less downtime on the combines to more productivity from the workforce at hand.

Harvest Faster: grain bags are helpful when it comes to supply chain issues and excess crops, as they’ll keep your harvest safe from wildlife, spoilage, and weather while you wait.

Increased Efficiency: grain bags help to deal with varied demand, as they offer both efficiency and storage to assist with your needs.

When it comes to challenges, farmers are no stranger to making it work. Farmers are more able to pivot than any other profession in the world, whether it be from weather, cost, or even global pandemics. With grain bags, you’ll be able to take some pressure off of your shoulders when it comes to incoming farming challenges.

-----

Now offering discounted pallet pricing when you buy four or more pallets of grain bags. For more information, talk to one of our agriculture specialists at your nearest Flaman location.

Posted in Ag news | Tagged with Pro Grain grain bags grain bagging grain baggers grain storage harvest | More articles by Calla Simpson

The Top 10 Reasons to Use Grain Bags

Posted by Calla Simpson Aug 04, 2020

Grain bagging has been gaining acclaim and popularity among farmers for being a resourceful, flexible, and time and money-saving grain storage option. The benefits are many, and farmers appreciate the efficiency of this innovative storage technique.

If you bag grain, you can expect to experience the following 10 benefits during your harvest season:

1. Saves the farmer's time.

When you bag grain, you reduce time loading grain into trucks and transporting it to grain bins or elevators. You can harvest the grain and store it right there in the field, which drastically cuts down on work time by eliminating so much back and forth to older, more traditional storage containers.

2. Increases harvest efficiency.

Grain bagging is easily the most flexible and efficient method for storing grain. You can store the bags anywhere that’s convenient (field, farm, or other lots), you have unlimited capacity, you have fewer labour constraints, you can move grain faster, and you can segregate grain variety easily into different storage bags. Overall, the processes during harvest are completely streamlined and made as productive as possible with grain bagging.

3. Improves commodity marketing.

Grain bagging preserves grain due to the ideal environment for grain within the bags themselves. When the bags are sealed, they are airtight, which eliminates the need for preservative chemicals and retains the grain quality. If commodity prices are low, and where storage constraints exist, bagging provides flexible unlimited storage. This allows farmers to control and plan the right time to market the crop for top dollar.

4. Reduces labour problems.

Because fewer trucks are required with grain bagging, your labour inefficiencies and costs will naturally reduce. Grain can be stored in the field where it’s bagged, which lowers the need for additional labourers.

5. Provides a storage solution for rented land.

For farmers who rent additional land and either don’t have their own storage bins, don’t have room in storage bins, or don’t want to deal with the cost and inconvenience of using the elevators, grain bagging allows easy storage for those rented land crops. There are virtually endless amounts of storage when you bag your grain.

6. Allows for unlimited storage capacity.

Even if you don’t rent land, if you have a bumper crop, or if your previous year’s crops are taking up storage space, you can utilize grain storage bags to safely and effectively store unlimited amounts of grain directly in the field.

7. Is a cost-efficient storage option.

You can store your grain in bags for about 7 cents per bushel (or less, in some cases). Alternatively, traditional grain bin storage can range anywhere from 14 cents to 37 cents per bushel, a massive expenditure in comparison to grain bagging.

8. Reliable and easily transportable.

After grain bags are sealed, oxygen levels decrease and carbon dioxide increases. This change in the environment can eliminate several strains of fungal diseases and insects without having to use harsh chemicals. Plus, when you are ready to market and sell the crops, you can unload them after harvest when it’s a more convenient time, more labour is available and truck costs are more sensible.

9. Expands the harvest window.

Farmers can start harvest operations earlier in the season and run later into fall by bagging grain that is higher than average moisture. You can unload the grain and dry it at a later time to lower the chance of bottlenecks at a grain dryer.

10. Improves the ability to avoid weather-related harvest issues.

Because your harvest operation will be moving faster and more efficiently, if there are weather delays or setbacks, you’ll be able to easily pivot and adjust your timeline. Your larger window for harvest also allows greater flexibility in dealing with weather restraints.

To learn more about grain bagging and to see which grain bagging products could improve your harvest capabilities, get in touch with us. We would be happy to walk you through everything you require for your grain bagging needs and answer any questions you might have.

-----

Now offering discounted pallet pricing when you buy four or more pallets of grain bags. For more information, talk to one of our agriculture specialists at your nearest Flaman location.

Posted in Product Information | Tagged with Pro Grain grain bags grain bagging grain baggers grain storage harvest | More articles by Calla Simpson

A Brief History of the Newest Flaman Store in Swift Current

Posted by Jennifer Thompson Jul 07, 2020

Flaman Group of Companies started on the farm over 60 years ago, when founder Frank Flaman saw a way to help other farmers by buying bins in bulk. That spirit of “making things better” for the farming community continues on today, so when Flaman had the opportunity to partner with an innovative, farm-focused company like Gatco Manufacturing, known for its quality products designed for farmers, the choice was easy.

The Flaman Swift Current and Gatco location

Products Designed by a Farmer, For Farmers

Gatco was started by a Saskatoon area farmer, Gary Schreiner. Schreiner had a problem: he was losing canola bins to overheating and needed a solution for remote bin yards that had no power. He began trying different combinations of perforated tubes in an effort to create a venting system inside the grain bin. This led to the creation of the GrainAir Tube powerless aeration system. The GrainAir tube allows heat and moisture to escape the bin quickly, by letting heat collect in the central tube and relying on convection to remove heat from the bin without any fans.

A couple year’s later, Schreiner was moving his load out auger and plastic hopper in his yard and slipped while maneuvering the plastic hopper. He knew there had to be a safer way to do this, and so the Auger Hog Hopper was born. This adjustable, detachable grain auger hopper attaches and detaches in seconds with a single mount pin, stays on your auger between bins, and adjusts from 12" to 29" in height merely by moving the handle. Due to the Auger Hog’s u-trough design, it also increases the average augers speed by 20-25% and prevents any product loss.

The Auger Hog

With the GrainAir tube working well, Schreiner felt there had to be a way to make a more efficient aeration system. While researching grain dryers, he found that air moved through grain easier horizontally, so he developed louvered wall columns that were pressurized with a common aeration fan. The air would leave the wall columns and travel horizontally to the central GrainAir tube and be released out through the bin lid quickly and easily. This CrossFlow system is far more efficient than traditional air systems, as the air travels less distance and moisture and heat is removed from the bin much faster.

“Gary came up with these unique solutions to help make farming easier,” says Bret Watson, Gatco division manager, who’s worked for the company since 2013.

Bret Watson (Gatco Division Manager & Flaman Operations Manager)

Bret Watson (Gatco Division Manager & Flaman Operations Manager)A Natural Partnership in Swift Current

It was that line of innovative, farmer-proven products that made Gatco a natural fit to join the Flaman team, says Watson, who is also the operations manager for Flaman’s Swift Current location. Gatco was purchased by Flaman Sales in 2018, when Schreiner decided he wanted to devote more time to his farming operation. “The companies are both family-owned and started on the farm,” says Watson. “We were selling to the same customers and trying to provide that same level of service. It was a nice, natural fit.”

With that purchase, Flaman Sales started their 7th store in Saskatchewan. The Swift Current location began as one-person business with Watson, but since February 2020 has added 5 more staff in sales, administration and yard staff, along with acquiring a second, 4-acre yard to expand on-hand inventory and provide better sales and service.

Mellissa Paxman (Administration), Bruce Deg (Ag Sales), Brittany Fiddler (Logistics Coordinator), and Rick Spanier (Yard & Support)

The Swift Current store is a full-service Flaman Agriculture equipment dealership, offering a wide range of in-stock grain-handling equipment such as augers, conveyors, post pounders, grain vacs, grain carts, grain bins, grain dryers, grain monitoring, and water and fertilizer tanks. Customers can also order products from the Flaman catalogue like discs, mowers, chem handlers, pumps, and more.

Bob Schafer (Ag Sales)

Bob Schafer (Ag Sales)“We’re proud to offer equipment options to the local community,” says Watson. “Farmers don’t have to drive to Saskatoon or Southey anymore. This location allows Flaman to serve customers all over southwest Saskatchewan.”

-----

Want to learn more? You can view some products in inventory or contact our Swift Current location.

Posted in Division News | Tagged with agriculture Swift Current Flaman new store local shop local southwest Saskatchewan | More articles by Jennifer Thompson

Flaman Dragon Slayers Rip Up the River!

Posted by Flaman Aug 22, 2014

Posted in Local News | Tagged with dragon boating Flaman Dragon Slayers Edmonton Dragon Boating Festival 2014 Rip up the River paddling | More articles by Flaman

Why built in Canada still matters

Posted by Steve Whittington Jul 25, 2014

.jpg) It was a Friday. I was at our Nisku location and I was leaving the dealership walking through the lot headed home for the weekend. I walked past a Trailtech TD 210 that had a few modified options on it. I looked the trailer over as I always do when walk past any unit in our yard. As I walked along the length of the unit from taillights to hitch I noted the features, fit and finish, quality of build, overall appearance, etc, etc, etc…when I reached the hitch I saw this trailer had just gone through our pre-delivery inspection process (as the sticker slapped on the front of the gooseneck indicated). I then stopped and looked back down the length of the trailer.

It was a Friday. I was at our Nisku location and I was leaving the dealership walking through the lot headed home for the weekend. I walked past a Trailtech TD 210 that had a few modified options on it. I looked the trailer over as I always do when walk past any unit in our yard. As I walked along the length of the unit from taillights to hitch I noted the features, fit and finish, quality of build, overall appearance, etc, etc, etc…when I reached the hitch I saw this trailer had just gone through our pre-delivery inspection process (as the sticker slapped on the front of the gooseneck indicated). I then stopped and looked back down the length of the trailer.

“This is a damn fine trailer” I thought to myself. So I took a closer look at the welds and the convenience features on the unit (some installed by us). I started to really critic the unit looking at the decking for cracks and other imperfections; I looked under the frame at the paint coverage; I followed the wiring harness (note I wrote wiring harness not strand wiring) along the frame paying attention to how it was secured and protected. Everything on this trailer was perfect. No matter how hard I looked I could not find any problems with the trailer. Quite honestly, this is not an exception to the rule, it is the rule: Trailtech product has outstanding consistent quality.

Call me bias (Trailtech is Canadian built, and a brand FGC has a longstanding history with) but I believe the quality that goes into to trailers built in Canada, for Canadian conditions is underappreciated. To address this I decided to give you reasons as a Canadian consumer why you should buy a Canadian built Trailtech.

1) Quality of Build. As in many products there are a good, better and best for light industrial trailers. At Flaman Group of Companies we sell products that fit into all three categories in order to meet the various needs of various customers. These categories are differentiated by features and quality which ultimately means different pricing. Trailtech as a brand offers a good, better and best models for each category. Where I believe they really shine (and customers have been voting this way with their dollars) is in the best category. The Premier and Industrial series generally have no equal in the market place. If you need a reliable trailer as a tool for your business, to me it makes sense to invest in a Trailtech that will always do what you need and last the test of time.

2) Canadian weather and road conditions. They are awful, both our roads and our weather and many trailer brands are built for the warm flat highways of the southern states as opposed to the gravel and pitted frozen highways of the Canadian north. For these conditions you need paint that can absorb some of the mechanical impact of road rocks at -40 and a RV plug that will not shatter when you fight to plug it into your tow vehicle. Trailtech based in Gravelburg SK lives in and understands these conditions. A Trailtech trailer is made to deal with this weather without fuss.

3) Warranty: We sell thousands of Trailtech products every year. They get horribly abused by some customers (another story) and yet we rarely hear of any issues. That said no company is perfect. The product is built by people and people make mistakes (as we all do). What defines a product and company is what they do when that happens. It has been my experience that between Trailtech and Flaman when a mistake happens that affects the customer, the Trailtech and Flaman people always make it right.

Lastly Americans market buy American all the time to support American companies and American workers. Let me be shameless and proudly yell the same thing: Buy Canadian! Yes I am a hypocrite as we sell many American brands across many of our divisions( including the Trailer Division). Being a leader in retail we need to provide the leading products in their appropriate categories in order to provide the best customer experience to our customers. That said, there are Canadian products that we sell that are the best in their categories (Trailtech is one of them)…Buy Canadian and support Canadians.

Posted in Product Information | Tagged with Trailtech Flatdeck Canadian built Trailers dump trailers ag transport | More articles by Steve Whittington

B & B Podcast

Posted by Steve Whittington Jun 03, 2014

Jim Behnke from Behnke Enterprises talks to Steve about Ag Transports and changes he has seen in his 27 year career in the Trailer Industry. Behnke Enterprises is a truly world class and worldwide brand with distribution in many countries and continents. Behnke Enterprises manufacturers a diverse product line of Ag Transport equipment and industrial trailers that allows evolving. Listen, learn, and enjoy the podcast.

Jim Behnke from Behnke Enterprises talks to Steve about Ag Transports and changes he has seen in his 27 year career in the Trailer Industry. Behnke Enterprises is a truly world class and worldwide brand with distribution in many countries and continents. Behnke Enterprises manufacturers a diverse product line of Ag Transport equipment and industrial trailers that allows evolving. Listen, learn, and enjoy the podcast.

Posted in Podcasts | Tagged with Podcast Flaman Trailers Steve Whittington Behnke Enterprises Ag Transport Industrial Trailers | More articles by Steve Whittington

Truck Boss Podcast

Posted by Steve Whittington Aug 19, 2013

Aidan Thygessen and Kent Natrass, joined me on a call to explain truck decks, the evolution of truck decks and how the Marathon Truckboss is the pinnacle of that evolution. Marathon has been building Truck Decks for 17 years there have been a lot of changes along the way. Today the Truckboss is much more than just a truck deck, have a listen and learn why the truck boss is shipped and used all over the world.

Aidan Thygessen and Kent Natrass, joined me on a call to explain truck decks, the evolution of truck decks and how the Marathon Truckboss is the pinnacle of that evolution. Marathon has been building Truck Decks for 17 years there have been a lot of changes along the way. Today the Truckboss is much more than just a truck deck, have a listen and learn why the truck boss is shipped and used all over the world.

Posted in Podcasts | Tagged with Trailer Talk Podcast Truck Boss Aidan Thygessen Kent Natrass Marathon sled deck sleddeck truck deck truckdeck truck cargo management system | More articles by Steve Whittington

Medicine Hat celebrates its Grand Opening

Posted by Adam Diakow May 17, 2013

On Wednesday May 8 Flaman Group of Companies in Medicine Hat held its grand opening to celebrate its new, larger location. We couldn’t have asked for a better day weather-wise, although this meant that most farmers were in the field and unable to attend.

We held a free BBQ lunch and had a great turn out. The official ribbon cutting was done at 12:30 p.m. by the Medicine Hat Chamber of Commerce and also in attendance was the mayor of Medicine Hat Norm Boucher.

To top off the day the Frank Flaman Foundation donated $7,000 to the Medicine Hat Women’s Shelter, which is the largest donation they had received to date.

The day couldn’t have gone better for everyone. Thanks to everyone who attended.

For more photos of the event, please visit our Facebook page here

Posted in Local News | Tagged with new store trailers fitness agriculture rentals Medicine Hat grand opening | More articles by Adam Diakow

Flaman Rentals introduces new Damage Waiver Fee

Posted by Flaman Apr 19, 2013

As of May 1, 2013, all Flaman Rentals stores and agriculture rental dealers across the prairies will be introducing a new damage waiver fee for all of our equipment rental customers. This new fee is designed to help our customers offset the high cost of equipment repairs if they accidentally damage any rental equipment while in their possession.

By paying this small fee, our customers can now feel good knowing they have coverage for any accidental damage to tools or equipment they rent from Flaman. This coverage could save them hundreds of dollars in repairs.

It’s just one more way Flaman is helping our customers have a positive rental experience, knowing that those expensive pieces of rental equipment are covered while in their possession.

Please stop in or call your nearest Flaman rental store for full details.

Flaman Rentals in Moosomin, Yorkton and Swan River currently offer a similar fee and this will remain unchanged.

Posted in Product Information | Tagged with Flaman Rentals rental renting equipment trailers damage waiver fee protection | More articles by Flaman

Third Time's A Charm

Posted by Jennifer Thompson Jun 26, 2012

For the third year in a row, Flaman Rentals in Saskatoon has been named a Consumer Choice Award Winner. This division of Flaman rents out enclosed and flat deck trailers, along with agricultural equipment like discs, land rollers or mowers.

I recently attended the Consumer Choice Award ceremony with our marketing VP Steve Whittington at the beautiful Delta Bessborough in Saskatoon. We got to sip champagne and rub elbows with a lot of great business owners in the city, and of course, celebrate our own success!

This award is special because the winners are picked by our customers. It means a lot to us that people recognize our efforts to offer great customer service. We were also very pleased to win a Consumer Choice Award three years in a row. This means our team is consistent taking care of our customers’ needs. And we’re proud of that!

What’s great is that the Consumer Choice Award is becoming a trusted name in the Saskatoon area. Looking at the other winners gathered in the room that night, we knew we were in good company amongst other top businesses in Saskatoon.

A big “thank you!” is due to our rental team in Saskatoon for all their efforts and hard work every day and to our customers for continuing to choose Flaman Rentals.

Steve Whittington (middle) receiving our award from Saskatoon Mayor Don Atchison and Consumer Choice Award President Marcel Sbrollini

Jennifer Thompson arriving at the awards ceremony.

Posted in Division News | Tagged with Consumer Choice Award Flaman Rentals trailer rentals agricultural equipment rentals customer service Saskatoon | More articles by Jennifer Thompson

New Rental flyer is out now

Posted by Flaman Mar 30, 2012

Flaman Rentals has just finished producing and distributing the new Rental Rate Flyer for our eastern Saskatchewan and western Manitoba rental stores. It contains details and safety information as well as rental rates on all of our most popular equipment.

Posted in Division News | Tagged with rentals equipment Flaman rates flyer construction agriculture trailers | More articles by Flaman

New website, new dealers for summer 2011

Posted by Barrett Prokopie Jul 05, 2011

This spring has been a very different one for many producers in the prairies, from near disastrous flooding in the southern parts of Saskatchewan and Manitoba, to drought in northern Alberta and B.C. It seems that nothing is predictable in the agricultural sector anymore (if it ever was).

Posted in Division News | Tagged with rentals new website dealers ag equipment trailers Saskatchewan Alberta | More articles by Barrett Prokopie

Locations

Locations