Flaman Rentals Blog

RSS feed

Categories

Recent activity

- What's it like being a Flaman Rental Dealer?

- A Brief History of the Newest Flaman Store in Swift Current

- Disney's NEW Leadership Excellence Training Course

- Disney's Approach To Quality Service

- Disney's Approach To Quality Service

- Trailering 'Rules of the Road' Updated

- 10th Annual Frank J. Flaman Foundation Gala 2016

- Why Frank Cares

Authors

Archive

How a Bench Custom Grain Cleaner More Than Pays for Itself

Posted by Jeff Brown Nov 19, 2024

It’s a scene that’s played out on farm after farm across Canada. Flaman Sales Specialist James Vanbeselaere positions your input and output augers, sets four levelling jacks, flips a switch on the central electric panel, and another farmer is in business.

If you’ve read our other Bench Custom Grain Cleaners Blog, you know that the business of on-farm grain cleaning makes good long-term economic sense. That blog discussed the savings you could bank, potentially over decades. With James’s help, this one details the ease, versatility, and benefits of operating your own personally customized cleaner.

Easy Start Up

“They usually reach us somewhat assembled, so we can pull it out to the customers already set up to go,” James explains. Very little time elapses between when it arrives in your yard and when it starts running - just enough to complete the wiring and the steps outlined above.

Ease of Use

The first goal of customizing a Bench cleaner is customer convenience. The central electric panel gives users quick, easy-to-reach, and unobstructed access to the Variable Frequency Drive (VFD) controls that govern their intake and output auger speeds.

Customers are also likely to admire the convenient method Bench devised for changing screens.

“The A1door latch system is unlike some cleaners that have grader shells you have to unbolt to take off,” James explains. “You wouldn’t have to do that with an Airens screen.” The Bench method is an easy slide-out, slide-back-in process, as James demonstrates in this video.

Dockage doesn’t stand a chance.

“The Bench 54 by 72-inch portable grain cleaner would probably be our most popular unit,” James says. That unit is equipped with components from another manufacturer, Premier Grain Cleaner of Minneapolis-Saint Paul, Minnesota. Like other Bench models, it does just about everything you could ask to winnow out everything but the top-quality grain you want.

Lighter material is immediately vacuumed away by the Cyclo air system pre-aspirator. Vibrating shaker shoes vibrate the scalp deck, grade deck, and sift deck. Each shoe sits above bouncing balls that help move materials to screens where they either fall through to the next layer or are taken off as dockage. That and a final round of Cyclo aspiration effectively removes everything from straw and rocks to fine chaff.

A Team of Machines

There’s even more you can do to deliver pristine commodities, thanks to Bench’s modular extensions. If you’re cleaning barley, you may want to start with a Bench de-bearder to improve your commodity’s flow-ability going into the grain cleaner - and its test weight afterward.

Once you’ve filtered the impurities out of your grain, you can take out the broken kernels using an indent screen. This screen is wrapped around a rotating drum, using centrifugal force to hold kernels of a desired length in the screen’s pockets while smaller kernels fall off the drum and are taken off as dockage. It’s a popular item, for good reason, as James explains.

“There were some grain cleaners we sold in La Crête, Alberta that had just Airens screens with indents because he’s mainly cleaning wheat. They grow a lot of wheat and canola up there.” Indent screens are ideal for longer-grain crops like wheat, which has been the commodity that creates the most demand for grain cleaning, James says.

Portable Possibilities

Wheat may be the crop most customers want to clean, but Bench provides options for a wide spectrum of cereal, oilseed, and pulse crops. Priding itself on versatility as well as portability, Bench offers cleaning equipment designed to handle barley, beans, canola, chickpeas, flax, oats, soybeans and sunflowers.

Flaman also has its own screen distribution facility in Saskatoon. Like Bench, we offer an inventory that’s carefully selected to take excellent care of the crops you put in your bins.

Kind to Your Commodities. Easy on Electricity.

“It’s a gentle feed,” James says of Bench cleaners’ easy-going stability. Those carefully set levelling jacks prevent a great deal of commodity damage by offsetting uneven terrain, but Bench took its smooth, crop-friendly operation an extra step.

“There are eccentrics underneath that provide a counterbalance,” James says, adding mention of another important benefit: “Once the shaker’s moving back and forth, little horsepower is required to move the tray, because of the momentum. So, guys don’t have to worry about having a big enough power supply to run these.”

Like to Know More about Operating Your Own Custom Grain Cleaner?

Flaman Grain Systems experts are ready to show you in-stock Bench Grain Cleaners and answer any questions you have. Call or visit your nearest Flaman location to discuss effective, economical solutions to your farm’s specific requirements.

Posted in Product Information | Tagged with Grain Cleaning | More articles by Jeff Brown

The Benefits of Customized On-Farm Grain Cleaning

Posted by Jeff Brown Nov 19, 2024

"Every farm’s going to be different,” says James Vanbeselaere. “Every area will be different, depending on what they're trying to clean.” As a Flaman Sales Specialist who’s installed and fired up a lot of customized Bench grain cleaners for enterprising customers, he should know.

What he’s showing farmers is a viable alternative to the transport distances, fuel costs, and unloading cues they can see taking their commodities to seed cleaning plants.

Grain Cleaning Comes Home

“You're just paying an expense to have the other guy clean it,” James says. “A lot of custom cleaners charge about a dollar a bushel. We have customers that clean 10 to 20,000 bushels a year. So, they're spending, you know, upwards of 20 or $30,000 just to have their own grain cleaned. So why not keep that money in your own pocket and put it towards your own system? You'll be building an asset out of it."

That’s why Flaman Grain Systems took the next logical step in the evolution of grain cleaning. It forged a partnership with Great Falls, Montana manufacturer Bench Industries to make on-farm grain cleaning a viable option for more producers.

“That relationship was already formed before I started at Flaman,” James says. “So, I guess I’ve just continued it. They fit our needs. We can sell on-farm units in the right sizes for on-farm use.”

Identifying Your Needs. Formulating Your Solutions.

Bench builds their quality grain cleaners to customer specifications, often using farmer-supplied commodity samples as a starting point. They offer a variety of mobile and mini grain cleaners, plus accessories like the popular Airens screens.

“Bench will do a lot of the customization themselves.” James explains. A customer’s specifically recommended combination could start with a portable or modular air screen machine, mini air screen machine, mid-size grain and seed cleaner, or mobile screen machine and include a vital accessory like a debearder/rethrasher, vibratory conveyor, or separator.

Long-Term Reliability

The tens of thousands of dollars farmers can save doing their own grain cleaning every year can multiply over decades. Flaman has a record of choosing grain cleaners based on their potential long-term durability – choices that have often panned out impressively.

“We’ve got a lot of cleaners that have been around for a long time,” James says. “Twenty, thirty, forty years old. They last.”

“VFD” spells power savings and convenience.

Bench custom grain cleaners feature a frequency drive (VFD) that can reduce power consumption by up to 70%. It’s connected to the electrical panel, a single central point of power connection that gives you speed control over your incoming and outgoing augers.

Nationwide Home Grain Cleaning

Wheat farmers are most likely to take up what Flaman and Bench have to offer. There is also demand for cleaning other commodities. Bench equipment can process other cereal crops like oats and barley, as well as oilseed crops like canola, flax, soybeans, and sunflowers, and pulse crops like peas, chickpeas, and beans.

With Flaman operating its own screen distribution facility in Saskatoon, the two-company partnership can help diverse farming operations across the Prairies – and beyond. We try to be coast to coast, all across Canada.” Wherever they go, these units carry their value with them.

Cost Savings, Care, and Convenience

“We’re pretty competitive in the price range,” James says. But he adds the real economic benefit is the money and time farmers can save. “They’re cleaning their own grain, so they’re not paying for it.”

That’s before a slew of design benefits that make grain cleaning a more pleasant process from the moment your unit arrives on your farm. You can read about them here.

James answers two final questions you might already be asking.

What kind of customer does Flaman believe is a good fit for a Bench custom grain cleaner? With the variety of options Bench offers and the spectrum of commodities and working conditions they can handle, there’s only one answer:

“We’re open to everyone.”

So, how do you find out if a Bench custom grain cleaner is right for you?

“Contact your local farm and sales Rep.”

You can do so by calling or visiting your nearest Flaman location. Our grain cleaning experts will be happy to introduce you to the convenience, benefits, and economy of owning your own Bench custom grain cleaning system.

Posted in Product Information | Tagged with Grain Cleaning | More articles by Jeff Brown

Kwik Kleen Grain Separators. More than Dockage Removal.

Posted by Jeff Brown Oct 07, 2024

When you’re trying to take off a crop in a limited amount of time, there are some things you just don’t want in your bin or your transport truck. Dockage and small seeds from weeds like Kochia or volunteer canola can compromise the condition of your harvest while costing you extra time and money. But there’s something you can do about it.

Removing small seeds will increase airflow, which will speed up your drying time and reduce your risk of heating. Taking out chaff, thin kernels, and other forms of dockage will increase your bushel weight and quality, lowering your transport costs.

Kwik Kleen's high-capacity five-auger 572 and seven-auger 772 grain separators handle these tasks quickly and efficiently. They also help with farming techniques that maximize your land’s productivity.

They remove what you don’t want. The Kwik Kleen system is ideal for separating large and small materials, earning it a reputation for superior dockage removal. It’s designed to separate light product with advanced features for tasks like sizing barley and taking thins out of cereals. This will increase your bushel weight, and lower transport costs, because you’re carrying only the grain you want to ship and nothing else.

They’re made for intercropping. Planting two compatible crops in the same ground at the same time can yield several nutritional benefits. When the time comes to separate them, a Kwik Kleen is well suited to separating large and small commodities like barley and canola, chickpeas and flax, and peas and canola. They’re also helpful if you’re sorting out biproducts for other uses, like dockage for livestock feed.

Cost-effective, high-capacity, and efficient Kwik Kleen grain cleaners excel at dockage separation but can be easily adjusted to perform multiple grain separating tasks.

There’s much more to the Kwik Kleen. Mitch from Flaman walks you through the electrical or hydraulic drive option, available auger sizes, and the variety of screen options available. For more information, call or visit your nearest Flaman location.

Posted in Product Information | Tagged with Kwik Kleen Grain Cleaning | More articles by Jeff Brown

Three Phase Electricity for Grain Handling

Posted by Jeff Brown Nov 06, 2023

Three-Phrase Grain Handling Power. Doable. Valuable.

More acres seeded might mean more bushels brought into your bin yard. But it doesn't have to mean more work and expense. As farming grows, new technologies emerge to boost your grain operation's speed and efficiency.

Technology Boosts Productivity.

Grain Dryers like our AGI NECO and Oakland models are designed to run continuously and safely. There's no need for you to spend your time or hire a hand to supervise them. And with remote monitoring systems, you can spend more time working in the field.

The same goes for the Walinga Blower System. Its airflow can move dried grain to your dry bins at rates of up to 2,000 bushels an hour. Achieving those higher volumes depends on the size of your piping and your motor's horsepower. The latter can be a sticking point for many farmers.

Amping Up Your Operation

Most farming operations are still wired for single-phase power. The high-volume systems mentioned above require three-phase power, which hits its peak amplitude three times as often as single-phase for three times the power output. It’s the optimum circuit for power generation. Higher-phase systems prove too complicated and expensive to be worth pursuing.

Despite its benefits, Farmers aren't often eager to rewire their farms to facilitate three-phase. Fortunately, they don't have to.

How to Convert from Single to Three-Phase Power Safely and Affordably

Walinga Blower Systems and AGI NECO and Oakland grain dryers all employ VFD technology. Variable Feed Drives have two outstanding features. First, they allow your motor to slow down and speed up, limiting energy consumption to reduce your power bill.

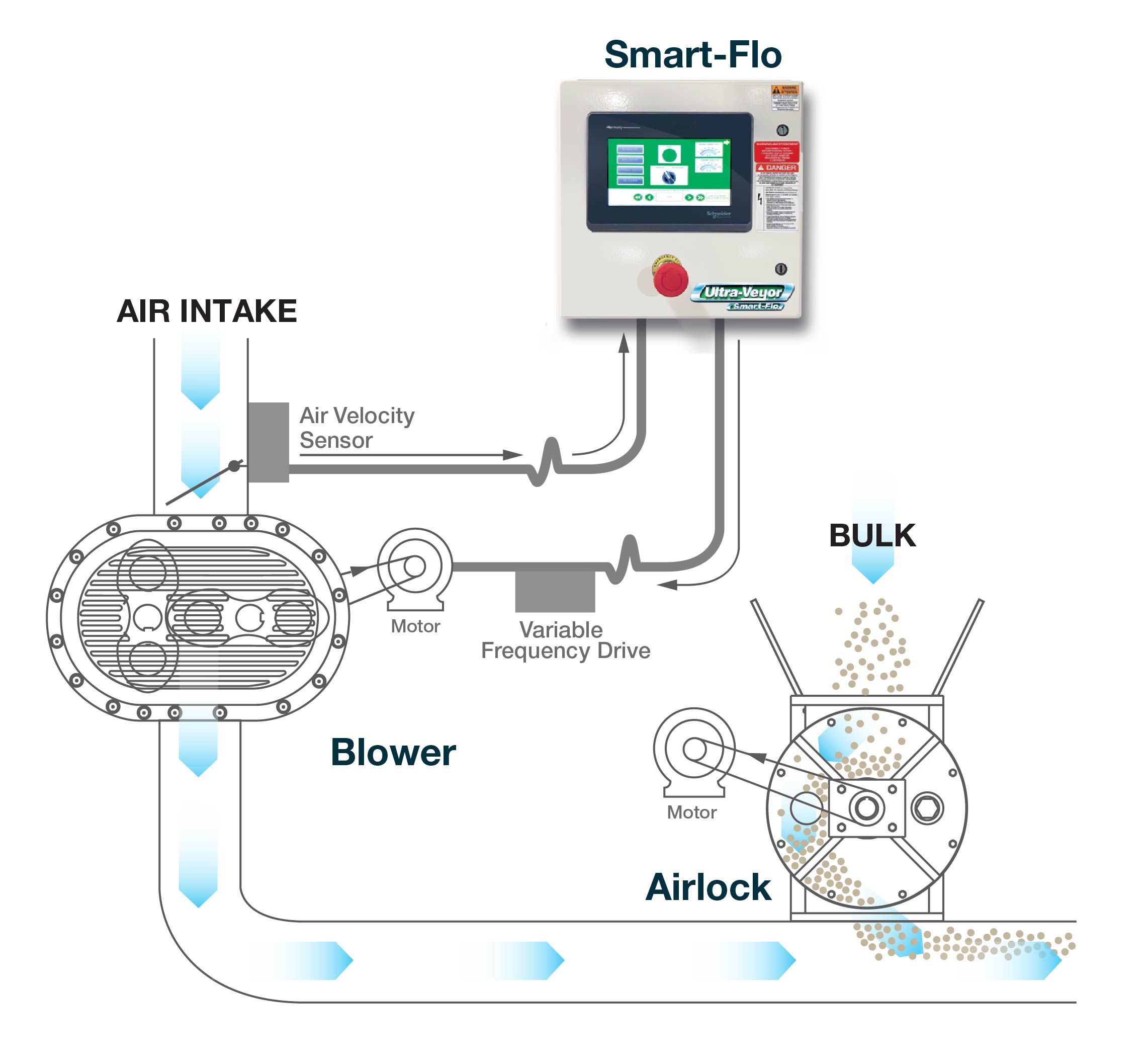

Walinga's Variable Frequency Drive Systems monitor and automatically adjust motor speeds

Walinga's Variable Frequency Drive Systems monitor and automatically adjust motor speeds

More importantly, they can be set up to draw current from your existing single-phase power source and convert it to three-phase electricity. So, you don't have to change your farm's entire power supply to run one or two bigger machines.

It's worth noting that not every variable frequency drive motor can deliver these results, but AGI, Oakland, and Walinga have engineered their motors with the farmer's single-phase/three-phase dilemma in mind.

Savings and Convenience to Help You Get Growing

There’s a big benefit to this small-scale phase shift. It removes a giant obstacle to building up your bin yard. Instead of waiting until you’ve saved up for a big change, you can increase your grain handling capacity in stages. More high-quality grain in your bin allows you to purchase more components down the road.

Ready to Lower Grain Handling Electricity Costs and Boost Production?

Get in touch with your local Flaman dealer and ask our bin yard experts how you can convert single-phase to three-phase power, add valuable components, and get your bin yard humming.

Posted in Product Information | Tagged with grain handling three phase power walinga neco oakland | More articles by Jeff Brown

Farmer-Approved Moisture Testing from Perten

Posted by Jeff Brown Jul 11, 2023

In agriculture, nothing is ever absolutely certain. However, farmers who’ve used the Perten AM 5200-Farm Moisture Meter say its instantaneous accuracy comes impressively close.

“When you have so many different people around - four different people using it - it was nice not to use the scale,” says Bruce Elke of Jansen, Saskatchewan. “Everybody puts it in and gets the same result.”

Bruce Elke shares the benefits of the Perten 5200-Farm

It’s not the first moisture tester to have its accuracy praised, not even the first one Bruce has praised. His previous tester was also bang-on, but the 5200-Farm brings something extra to the table. “I think really it was the ease of use and just taking out the possibilities of error,” he says.

“Customers like that,” observes Shaun Gettis, Vice President of Sales at Flaman. “No need to weigh or take temperature tests.”

A Simple Process

For a machine that delivers precise moisture reports for various grains, oilseeds, pulses, beans, lentils, seeds, and more the 5200-Farm is a breeze to operate.

Just select the grain type you’re analyzing from an extensive onscreen menu showing virtually every type available in North America. You can then enter ID info for your sample, saving your bin number, test date, and time for future reference.

-2 Edit B copy.jpg)

Then scoop your sample in until the 5200’s cup is full and click GO. The tester intuitively takes the prescribed weight it needs and removes the excess. After a 25-second analysis, your sample’s moisture, bushel weight, and temperature all show up on the 5200’s colour touch-screen display. Every kernel in the machine drops into a clean-out drawer for easy removal. Need to do another sample? Just hit NEXT.

“There was no chance of finding the wrong page in the book or using the wrong weight and having mistakes made,” says Bruce Elke. “That was one of the things that I really liked.”

Reliable Readings. Customer Confidence.

The moisture curve remains accurate throughout a wide range of temperatures. That’s critical for farmers drying grain or harvesting on hot days. Not surprisingly, it’s one of the benefits potential users are most curious about.

Some have seen the Perten 5200-Farm at work in their local elevator. Others have had a Flaman rep bring one out to their farm to demonstrate the tester’s advanced accuracy sampling their own grain, and the response has been positive.

Ask your local Flaman sales rep about an on-farm demo

“Farmers like that the test data is logged,” says Shaun Gettis. “The bushel weight gives them more insight into their grain.” That, along with consistent, reliable moisture testing results – even in extreme temperatures – allows producers to make their combining and grain drying decisions with confidence, which is value for money.

Experience Perten AM 5200-Farm Accuracy at Flaman

Call or visit your nearest Flaman location to discuss how the 5200 can give you confidence in your crop’s readiness. Talk to a moisture-testing expert at any of our 11 locations across Manitoba, Saskatchewan, and Alberta.

Posted in Product Information | Tagged with perten grain analysis moisture testing | More articles by Jeff Brown

Five Reasons to Upgrade Your Grain Handling

Posted by Jeff Brown Jun 20, 2023

Wish managing your bin yard was a little less complicated? A tied-in grain-handling system can make that happen. Flaman offers several innovative components that can eliminate the effort, expense, and inconvenience of getting your grain safely in your bins. Bringing them together in one place yields a bumper crop of benefits.

1. Reduce Manpower and Save on Labour Costs

Consider all the moving parts involved in traditional grain handling – augers, tractors, and semis to drive in and unload, plus the manpower to keep them moving. Setting up a grain handling system can save you the time it takes to move and operate equipment plus the expense of hiring help.

Options like belly dumping or side dumping grain into a pit that feeds a bucket elevator can be done by one person – saving you a lot of hiring, hollering, and hand signals.

2. Minimize Maintenance Costs

You’re probably all too aware of the cost of running a tractor back and forth to your grain bins. In addition to fuel, extra operating time will also mean more wear and maintenance. Your auger flighting can also wear out, suffering more metal-on-metal damage as time goes by.

A self-propelled, belt-driven bucket elevator is designed to avoid impact points, and a pit system can eliminate the need for a tractor to move or power anything.

copy.jpg)

3. Eliminate Seed and Grain Damage

Of course, if metal can damage metal, it can easily crush any seed that gets caught between an auger’s flighting and its tube. Brittle pulses like lentils and peas are particularly vulnerable to significant and costly damage.

A gentler handling option makes good economic sense. You could employ a low-cost Hutchinson Chain Loop system, operating like a sideways-mounted bucket elevator, or you could opt for the bucket elevator itself, which carries your grain in plastic buckets for minimum damage.

Walinga’s air system takes seed and grain protection even further. Its vacuum intake and blower combo gives your crop an air-cushioned ride to the bin.

4. Invest in the Future Growth of Your Operation with a Staged Expansion Approach

Not everyone can afford to set up a state-of-the-art grain handling system on day one. Fortunately, Flaman can help you structure a budget-friendly plan to expand your grain operation whenever and however you feel comfortable.

You can build up in stages over a number of years. For instance, Stage 1 might mean setting up a reliable bin-and-auger process. Your second stage might include tying all your bins together with a grated pit and bucket elevator system. In stage 3, you might add grain storage or introduce a truck scale or an overhead unload bin you can drive your truck under. Your fourth stage might see the addition of cleaning and processing equipment.

This is just an example. You could switch it up to expand your operation as you see fit. Every customer is different, and Flaman helps each one find an individual solution.

5. Increase Efficiency

Nothing saves time and money like speed and volume. Flaman offers both. Our low-maintenance grain handling equipment is proven to provide a high degree of safety for your crop and yourself. These include grain-moving options with impressive capacities of up to 20,000 bushels an hour.

From Start to Finish, We Have It Handled

If you’d like to make life on the farm more than kinda laid-back, Flaman proudly offers the best-in-class industry experts to help you do it.

You can count on our team of certified technicians. Their collective grain-handling expertise, service, and support are yours throughout the setup, optimization, and maintenance of your operation.

Get efficient this year. Talk to Flaman about the grain handling options that can start saving you money – and about the expansion you can achieve with the money you save.

Start your better bin yard conversation by calling or visiting your nearest Flaman Agriculture Location.

Posted in Product Information | Tagged with grain handling walinga bucket elevator hutchinson grain pump | More articles by Jeff Brown

Be ready for harvest 2022: Summer is the time to build your bins & install your grain handling equipment

Posted by Calla Simpson Jun 24, 2022

Now that seeding is complete and the crops are growing, you may be starting to think about the next steps in your farming operation for 2022. This likely includes thoughts of additional Grain Storage, Grain Handling, and even Grain Drying equipment.

It may seem early to plan for harvest, but summer is a great time to build your bins and install your grain handling equipment to move the crop come harvest time. Buying now will ensure your equipment is installed and ready to go in the fall – so you can have peace of mind all season long.

Lean on the Pros

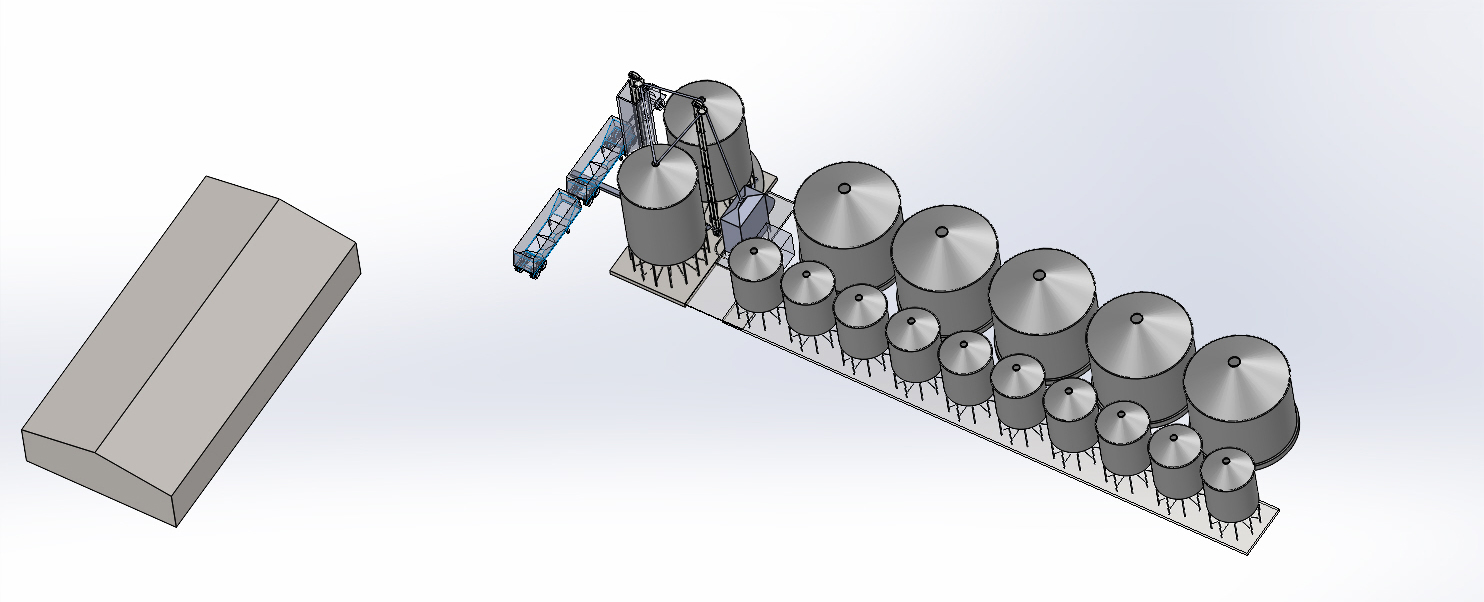

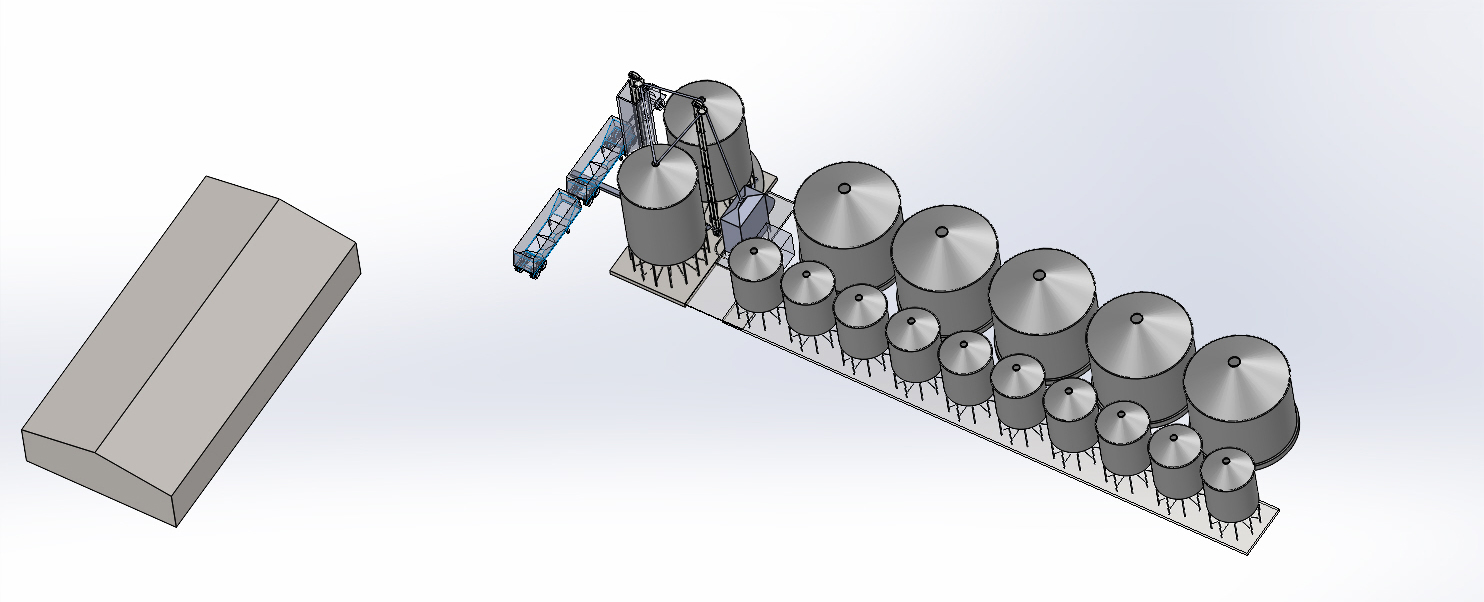

At Flaman, our Grain Systems team is equipped to work with you on developing your yard for the future. Let one of our industry experts come to your yard to measure, draw, and discuss your needs for the coming year. Our tactical approach provides you with various drawings and site layouts that can utilize your existing equipment, and plan for future expansion in a multi-phased strategy.

We can create a yard design based on your operational needs and the desired function of your site.

We specialize in full grain handling setups, including a wide range of bucket elevators and pneumatic conveyors – such as the Walinga Ultra-Veyor. Our turn-key offering also includes grain dryer systems, like the NECO Mixed Flow Dryer, as well as grain cleaning and processing facilities, automated bin sites, and producer loading sites.

Our team is here to guide the entire setup and installation process of your grain handling system and provide maintenance and service for every item that goes in and out of our doors.

Schedule your appointment today for a free, no commitment site assessment.

-----

For more information on our grain handling and grain drying solutions, talk to one of our agriculture specialists at your nearest Flaman location.

Posted in Ag news | Tagged with grain systems grain handling grain drying grain cleaning turnkey bin site NECO Walinga | More articles by Calla Simpson

Grain Cart Unloading Done Just Right

Posted by Jeff Brown Jun 16, 2022

It really does matter how you look at it. Watching those harvest bushels pour out of your auger may do your heart good, but your back and neck don’t fare so well.

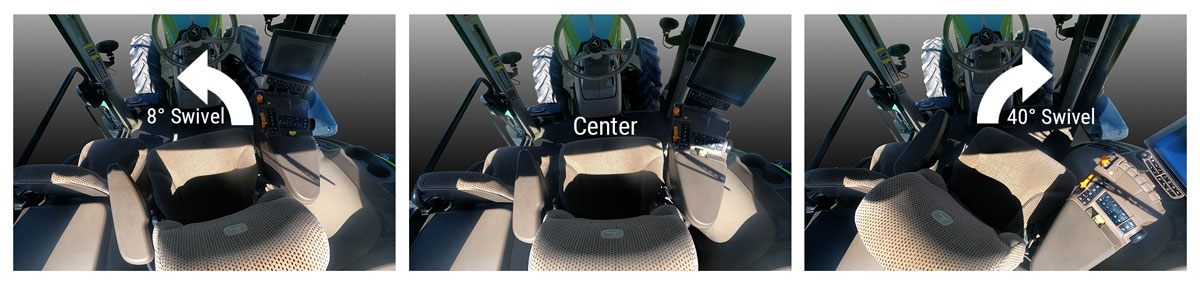

That’s because traditional grain carts unload on the left-hand side, causing you to turn away from your tractor controls. Meanwhile, anyone in your buddy seat has to do his own contortions to stay out of your way while you try to accurately offload grain. All that straining and stretching to see what’s happening makes for a long, unpleasant day - and a sore, sleepless night.

Thankfully, one simple common-sense improvement gives you a clear view of your auger without the aches and pains.

Right-side augers change everything!

J&M Manufacturing’s right-side auger grain cart makes the most of your tractor’s cab layout. Easy access to controls and unobstructed visibility allow you to effortlessly aim your auger right into the semi-trailers. The increased comfort makes grain handling more operator-friendly— with fewer visits to the chiropractor.

It works with the extended right-hand swivel of most tractor seats and provides a consistently clear view of your controls and monitors. No more groping around, hitting the wrong button, and spilling your valuable grain.

Farmer Approved

Operators have noted the left-to-right change left them less fatigued at the end of the day.

“It's hard to look to your left when your controls are on the right. It’s just a piece of cake.”

Bill Carter, Carter Farms

Different Side. Same Great Quality.

J&M builds their right-side auger model to the same high-quality standards as the rest of their grain cart line. All components and wearable parts remain as durable, dependable, and available as ever. Only the auger position has changed, and it's just one of this cart’s outstanding features.

Speed, Accuracy, and Convenience

The X-tended reach straight auger enables you to transfer 1400 bushels of grain in 2.5 minutes. Meanwhile, J&M’s patented telescoping hydraulic flow control spout sharpens your offloading aim – reducing the amount of grain that spills on the ground.

A 3-position auger system offers a 'storage' position to reduce machine width during transport and parking. The 'field' position limits stress on the auger and keeps the auger clean of any mud. The auger quickly extends to the 'unload' position to drop grain off.

J&M Grain Carts at Flaman

Flaman carries the J&M 1412 grain cart with single 32” wide wheels or a 36” V4 Track to reduce soil compaction. Other heavy-duty standard components include:

- V-Truss axles designed for strength, preventing twisting or bending

- Oversized 6” spindles

- 10-bolt and 20-bolt hubs available

- Computer-balanced bullet auger flighting for quick unload speed and durability

All of our 1412 X-tended reach right-side auger grain carts will be wrapped with special edition Canadian decals, and will feature an iFarm scale, rolling tarp, and 1 ¾" PTO drive.

------

Numbers are limited for 2022. Contact your nearest Flaman Ag expert and reserve your new J&M right-side auger grain cart today!

Posted in New Products | Tagged with J&M grain carts right side auger x-tended reach grain handling harvest | More articles by Jeff Brown

Why You Should Choose Flaman for Your Next Custom Screen Project

Posted by Calla Simpson Mar 18, 2022

Flaman Grain Systems is Western Canada’s largest custom screen manufacturer.

Not only do we stock over 50 varieties of material for any type of screen you may need, but we also have a team with over 50 years of combined experience in the Grain Systems industry.

From large terminals to small plants, we ship custom screen orders anywhere in North America – but especially throughout the prairies.

Inventory

One of the advantages of working with Flaman for your custom grain cleaning screens is our extensive inventory. We have 54 different types of screen materials in stock and on the shelf, as well as the frames to go with them.

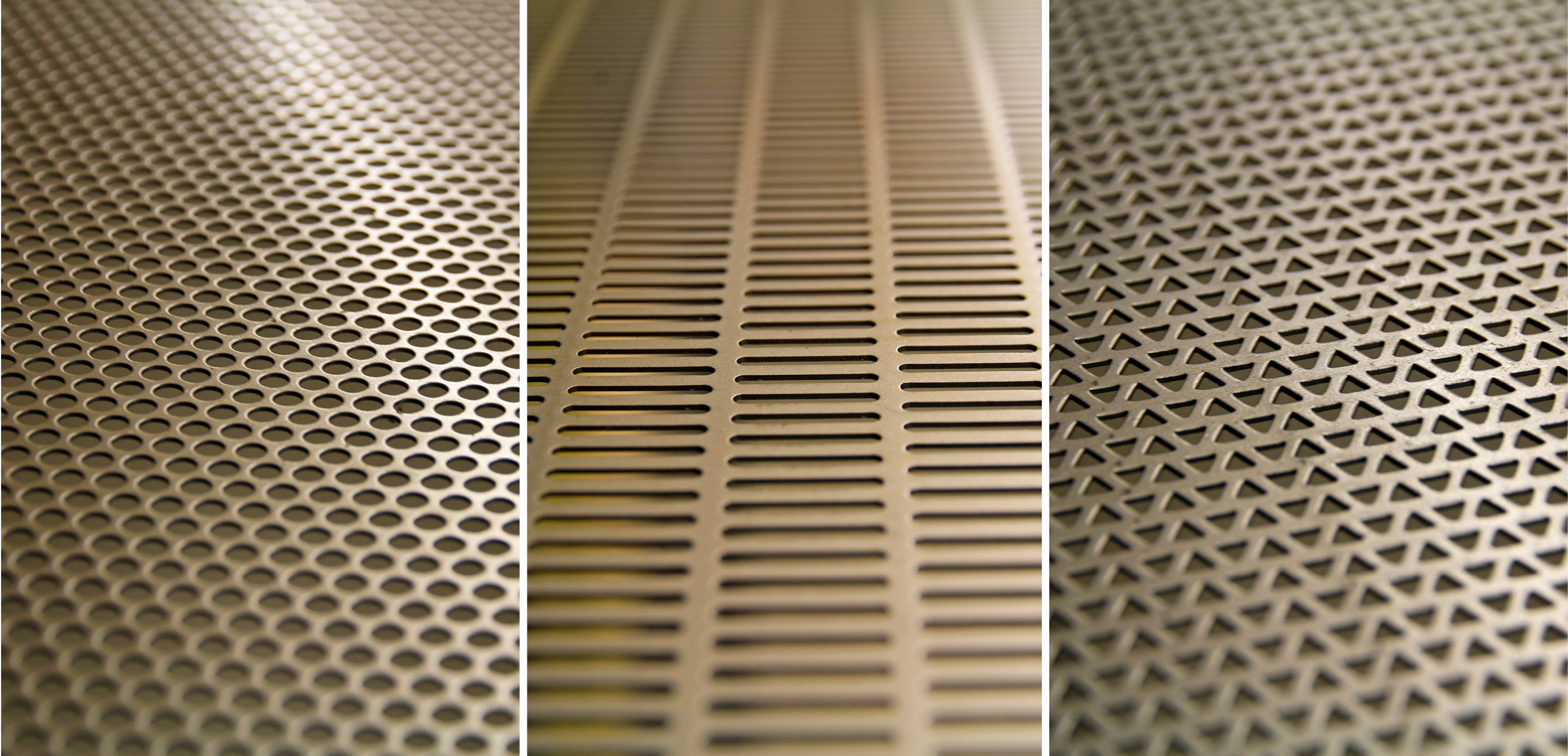

Round Hole, Slotted, and Triangular Screen Options

Round Hole, Slotted, and Triangular Screen Options

We have screens available for almost any make or model cleaner, as well as custom-built to your specifications. We offer round hole, slotted, triangular, wire mesh, and specialty perforating screens, with either wooden or aluminum frames.

Grader Shells

Grader Shells

We also carry grader shells, scalper reels, indent shells, and ball racks, along with a full supply of durable hand screens and sieves in a variety of materials and sizes. Specialty order hand screens are also available.

Hand Screens & Sieves

Hand Screens & Sieves

We begin by assessing your needs from technology to capacity, so we can accurately match you to the proper equipment for your grain cleaning operation. After we find the right machine for your farm or commercial operation, we work with you to determine the correct size and type of screen.

We hand screen grain samples for size and quality, so we can provide you with an accurate recommendation of screen sizes. Then we decide between wood or aluminum frames, wire meshes, or specialty orders, as well as any other accessories or add-ons.

All of our screens are manufactured in-house out of our Grain Systems shop in Saskatoon, Saskatchewan.

Experience

When it comes to our screen division, it is our people that really make the difference. From sales and operations to carpentry and welding, our team has long-term experience in the Grain Systems industry.

With over 20 years of experience with Flaman, Roy prides himself on getting the right equipment in front of his customers. Roy’s extensive grain cleaning knowledge and his passion for helping find solutions for his customers is the foundation of the Grain Systems team.

“My favourite part of working with this team is the people. We have a lot of fun here, too.”

Roy, Shop Manager & Grain Systems Analyst

Roy, Shop Manager & Grain Systems Analyst

With a smile, Mike keeps the sales and operations side organized and running smoothly in a busy atmosphere.

Mike, Grain Systems Sales

Mike, Grain Systems Sales

Our screen manufacturers are integral to the shop and the Grain Systems team. They are consistent, hard-working, and skilled woodworking and metal manufacturers.

Josh, Screen Manufacturer

Gerwin, Screen Manufacturer

From Start to Finish

At Flaman Grain Systems, we believe in supporting you from start to finish – from screen manufacturing and operations, right up to processing plants and turn-key grain system installations. This includes supplying, installing, and servicing various grain cleaners, bucket elevator systems, and other grain handling equipment.

copy.jpg)

With our unmatched inventory and long-term experience, Flaman is a great choice for your next custom screen project.

When you buy from us you are not just buying a product, you are gaining the ongoing support of a team with over 50 years of experience.

-----

If you have any questions about screen manufacturing, or any of our on-farm or commercial grain cleaners, grain dryers, or grain handling equipment, contact us or visit your nearest Flaman location.

Posted in Division News | Tagged with grain systems grain cleaning grain cleaners screen manufacturing perforated screens custom screens processing plants | More articles by Calla Simpson

From start to finish, the Flaman Grain Systems team is right beside you

Posted by Mitch Flaman Apr 07, 2021

At Flaman, we understand that investing in your farming operation and expanding your yard site is important for continued growth and efficiency. That’s why we believe in supporting you from start to finish.

Customers share their experiences working with the Flaman team for their drying & handling setups (above)

Our Grain Systems team are experts in grain handling, grain drying, and grain cleaning. When you buy from us you are not just buying a product, you are gaining the ongoing support of a team with over 50 years of experience.

From Start to Finish

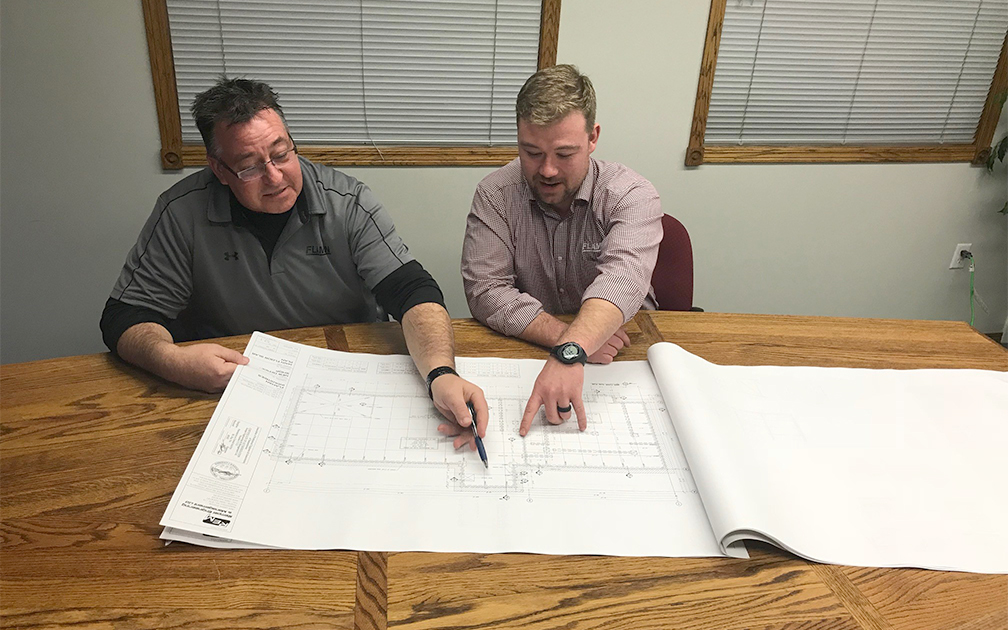

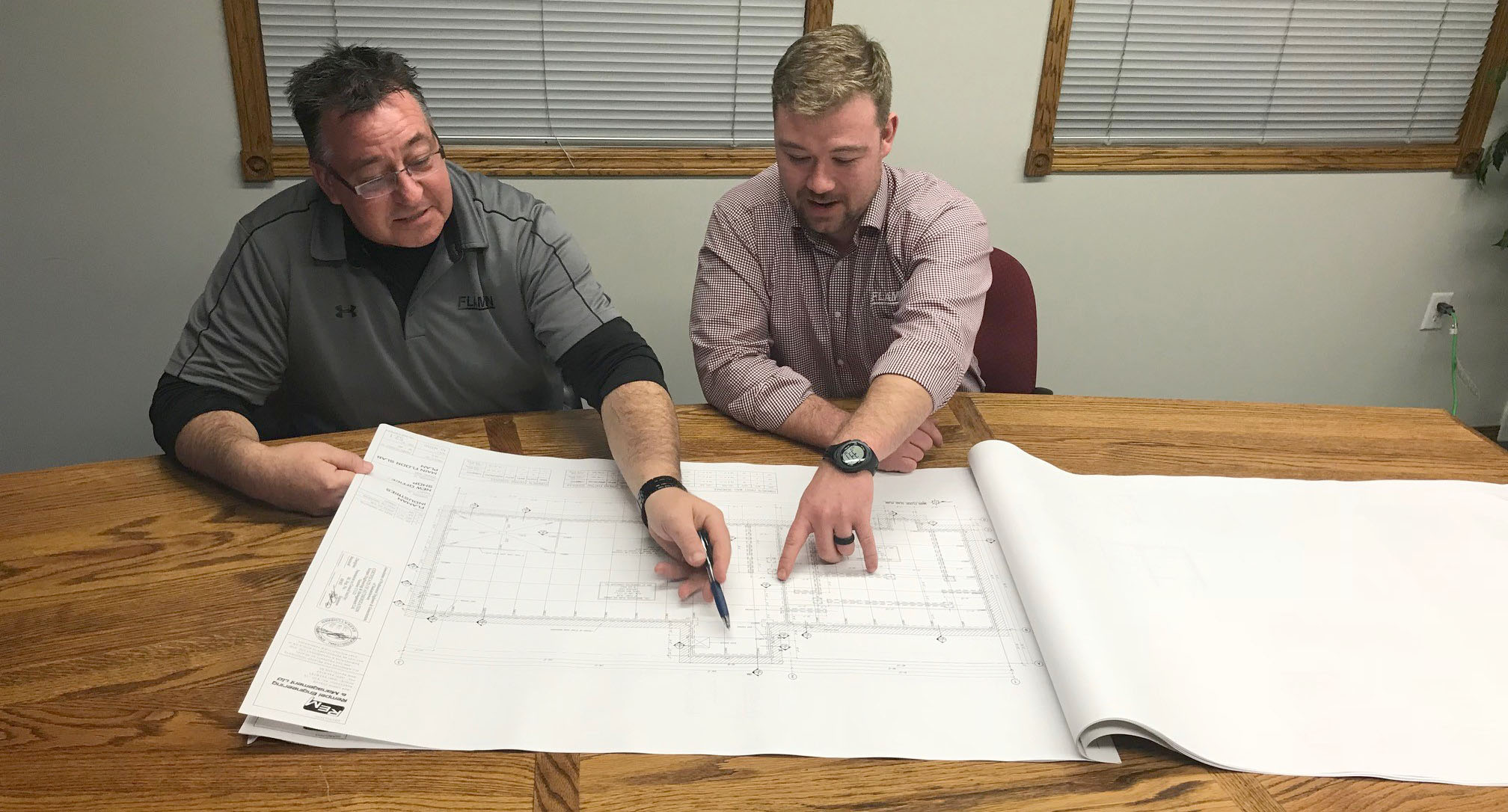

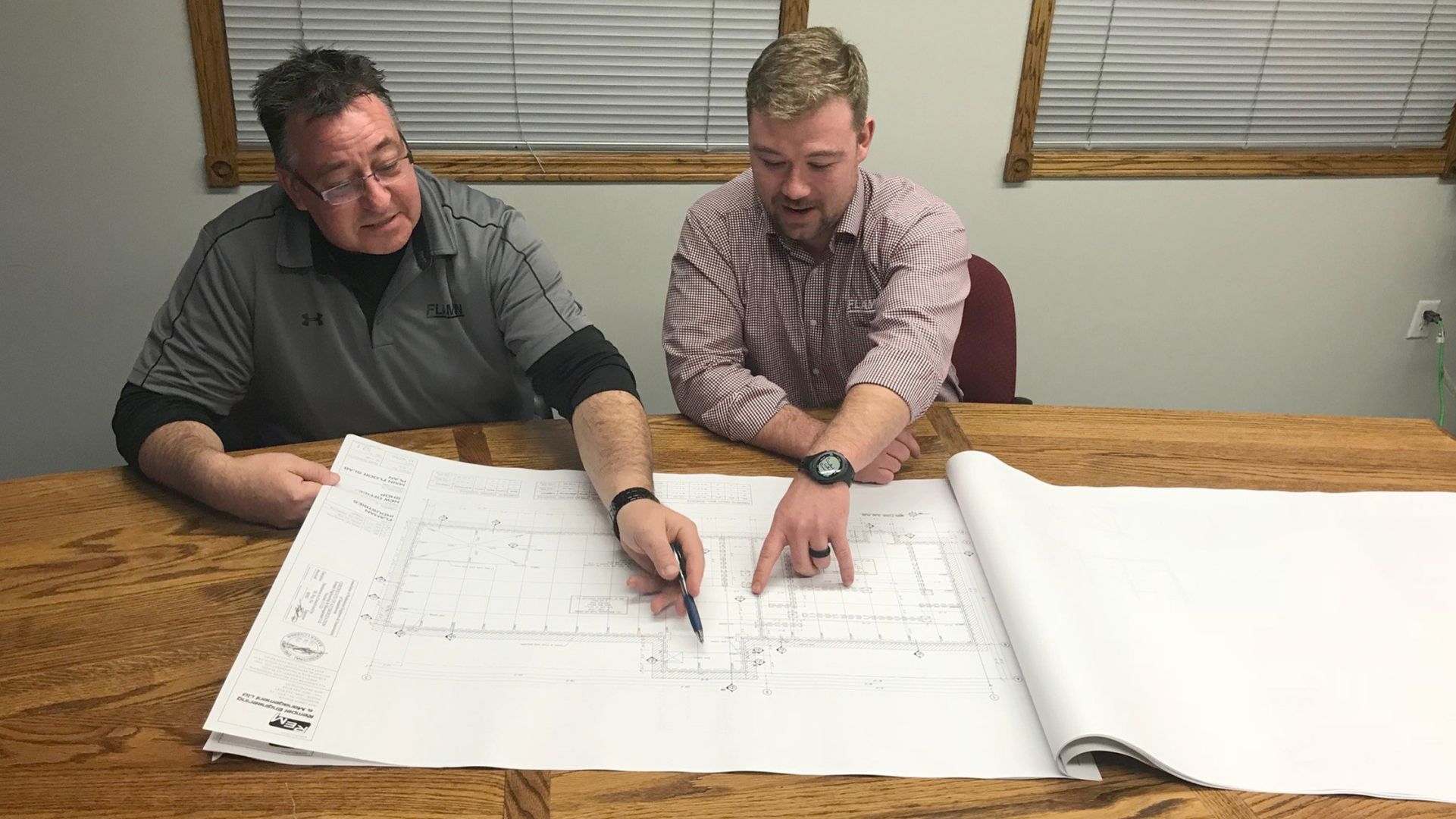

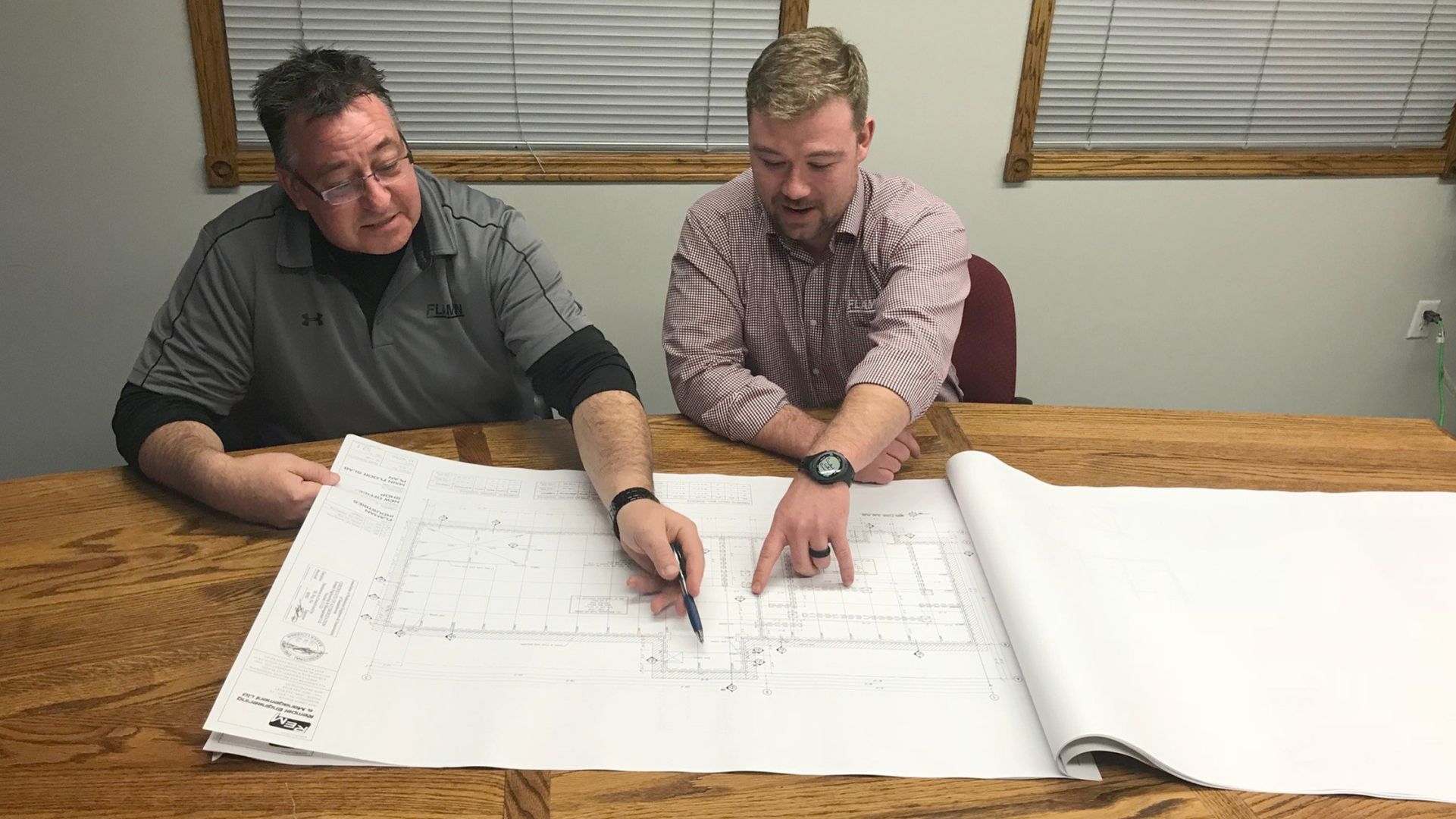

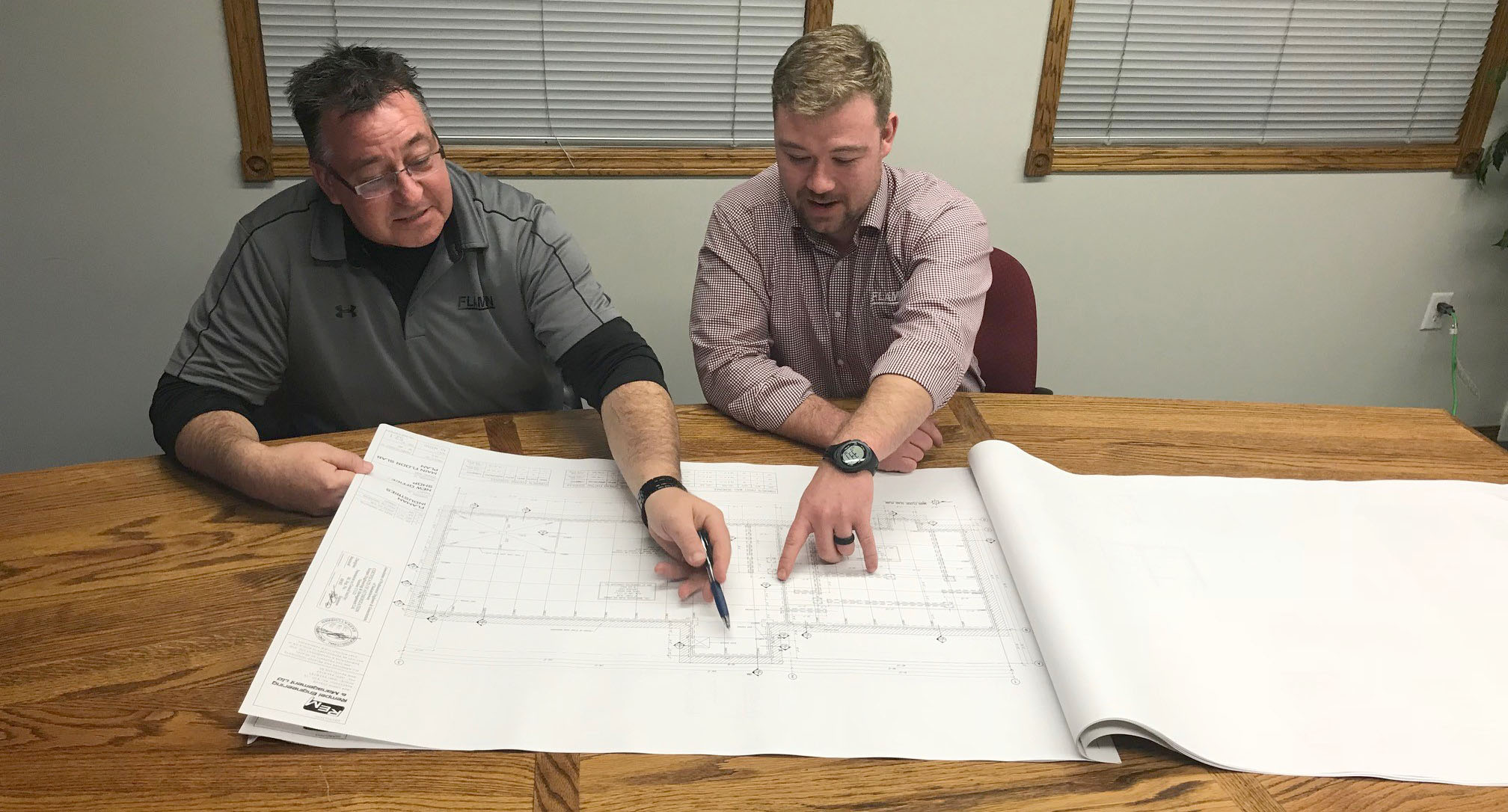

One of our industry experts will sit down with you to discuss and understand what your needs are for the coming year, as well as any future plans you may have. From there we will design a phased approach, with future expansion in mind.

We provide complete engineered drawings constructed in-house, with multiple alternatives to come up with a solution that works for your operation.

Once the equipment is decided on, we will continue to work with you through the site preparation and construction. Our job is not done until your equipment is handling grain the way you expect it to. And even then, we don’t consider our job to be done. Rather, we shift our focus to make sure you remain satisfied with the performance of your equipment.

That’s where our Service Team comes in. This dedicated team of certified technicians specializes in after sales support including warranty, pre-season and post-season maintenance, optimization, and commissioning of your machines to ensure your equipment is always running at peak performance.

Our Service Team Lead explains what you can expect from our team even after the sale (above)

We also offer access to a customer service hotline with live tech support after hours (in season only).

When you buy from us you are not just buying the equipment, you are buying the total solution. We have been here for over 60 years and we look forward to continuing to grow with you as your farming operation grows.

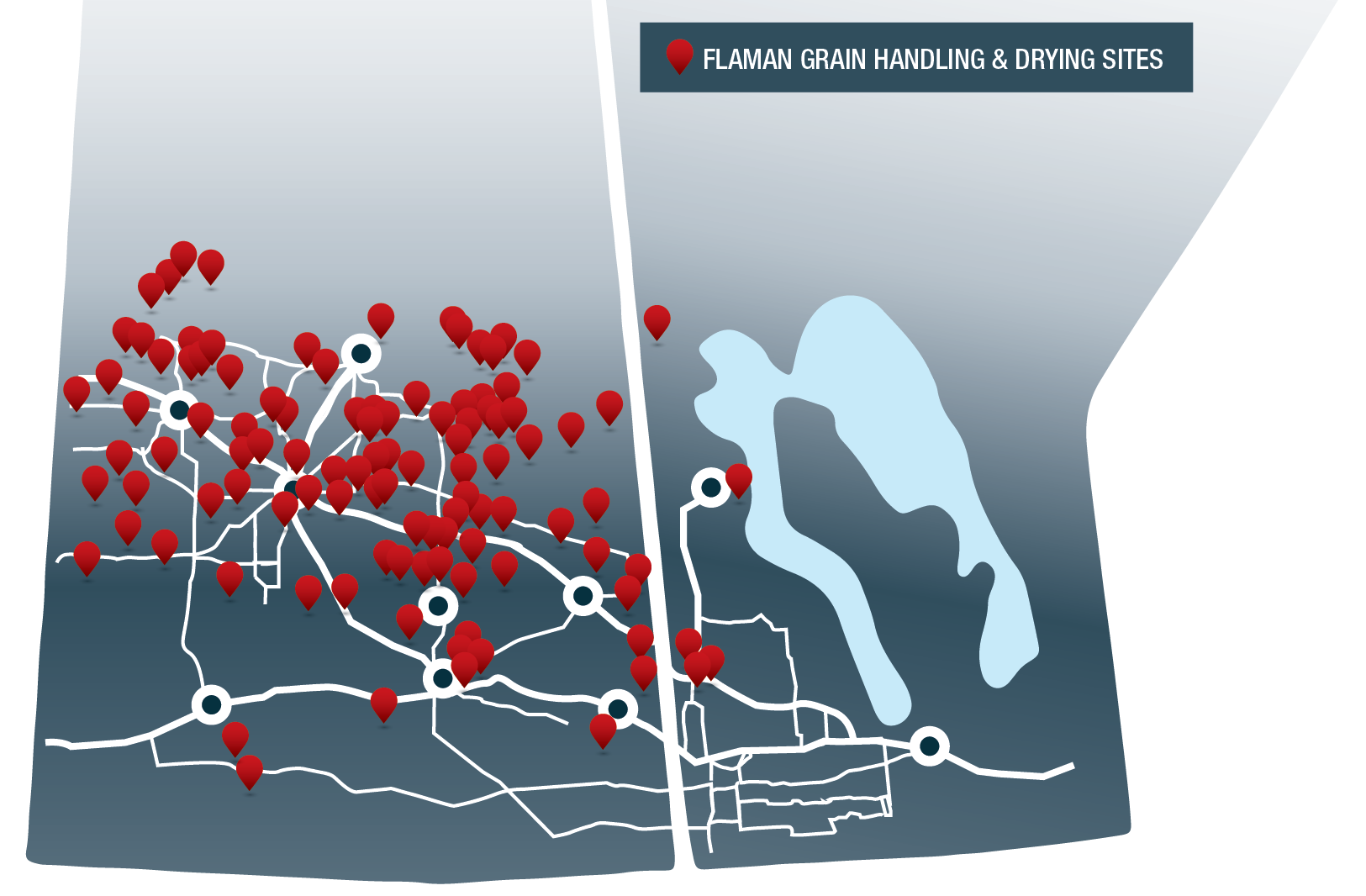

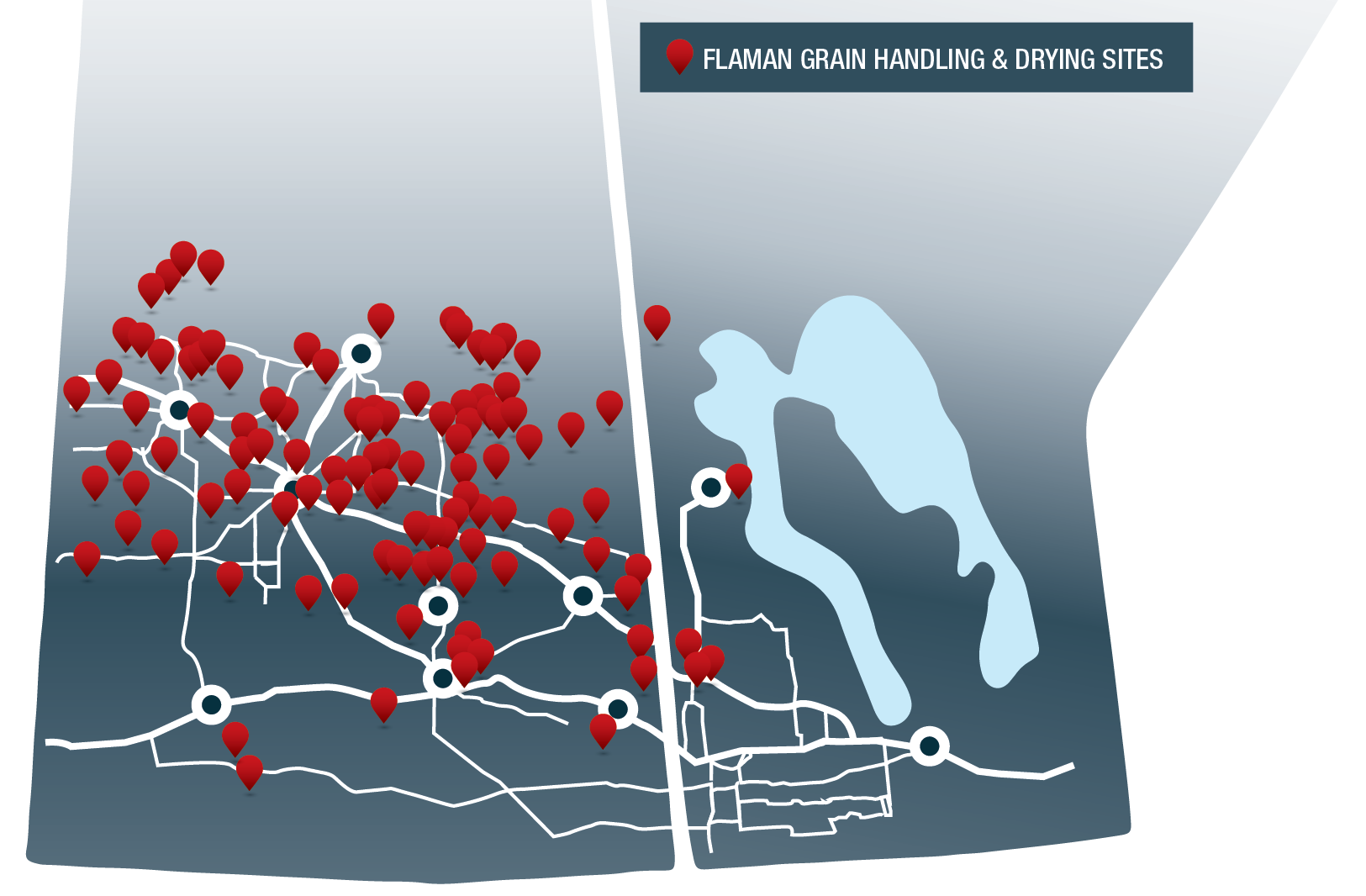

Map of Flaman Grain Handling and Drying sites throughout Saskatchewan & Manitoba (2021)

-----

If you are considering adding grain handling, drying, or cleaning equipment to your farm, give us a call or talk to one our Grain Systems specialists at your nearest Flaman location.

Posted in Division News | Tagged with grain systems grain handling grain drying grain cleaning optimization site drawings yard planning | More articles by Mitch Flaman

From start to finish, the Flaman Grain Systems team is right beside you

Posted by Mitch Flaman Apr 07, 2021

At Flaman, we understand that investing in your farming operation and expanding your yard site is important for continued growth and efficiency. That’s why we believe in supporting you from start to finish.

Customers share their experiences working with the Flaman team for their drying & handling setups

Our Grain Systems team are experts in grain handling, grain drying, and grain cleaning. When you buy from us you are not just buying a product, you are gaining the ongoing support of a team with over 50 years of experience.

From Start to Finish

One of our industry experts will sit down with you to discuss and understand what your needs are for the coming year, as well as any future plans you may have. From there we will design a phased approach, with future expansion in mind.

We provide complete engineered drawings constructed in-house, with multiple alternatives to come up with a solution that works for your operation.

Once the equipment is decided on, we will continue to work with you through the site preparation and construction. Our job is not done until your equipment is handling grain the way you expect it to. And even then, we don’t consider our job to be done. Rather, we shift our focus to make sure you remain satisfied with the performance of your equipment.

That’s where our Service Team comes in. This dedicated team of certified technicians specializes in after-sales support including warranty, pre-season and post-season maintenance, optimization, and commissioning of your machines to ensure your equipment is always running at peak performance.

Our Service Team Lead explains what you can expect from our team even after the sale

We also offer access to a customer service hotline with live tech support after hours (in season only).

When you buy from us you are not just buying the equipment, you are buying the total solution. We have been here for over 60 years and we look forward to continuing to grow with you as your farming operation grows.

Map of Flaman Grain Handling and Drying sites throughout Saskatchewan & Manitoba (2021)

-----

If you are considering adding grain handling, drying, or cleaning equipment to your farm, give us a call or talk to one our Grain Systems specialists at your nearest Flaman location.

Posted in Division News | Tagged with grain systems grain handling grain drying grain cleaning optimization site drawings yard planning | More articles by Mitch Flaman

Three reasons the Batco BCX3 needs to be your next conveyor

Posted by Mitch Flaman Jan 21, 2021

It’s here. The legendary orange “gentle giant” from AGI/Batco has received more than a facelift for 2021. After a complete redesign from hopper to downspout, the BCX3 conveyor has a few new features worth bragging about. Aside from the redesigned S-Drive, new Turbo-Clean Wash System, and remodeled fuel tank, there are still 3 big upgrades that make this the most versatile conveyor yet.

- Move All Commodities - Most notably, the biggest feature of 2021 is the BCX3 conveyor’s ability to move all farm commodities - that’s right, INCLUDING CANOLA. Gentle on pulses, quick on cereals, and capable of oilseeds, you now have one tool for all your jobs. This has been made possible with a redesigned hopper & downspout, plus the new Turbo-Clean wash system with multiple scrapers & brushes. As with the use of any oilseed, additional maintenance and cleaning is required to ensure the longevity of your conveyor.

- Multiple Controls, One Location - Redesigned, with functionality and safety in mind, you will find all the controls in one location. This means you can adjust the throttle, engage the clutch, change the height for both hopper & discharge, and drive all from one spot. No more reaching. The conveyor’s control center has been relocated to provide better ergonomics and visibility as you drive, as well as additional clearance when setting up underneath your hopper.

Ergonomic Command Centre

- Move with Ease - A completely redesigned mover adds substantial traction and maneuverability for your conveyor. The new all-terrain tire design has been coupled with an internal braking system to prevent rollback. The drop-and-go design is simple and safe - no more engaging or locking hubs. The drive wheel has been relocated to better utilize the weight distribution of the conveyor. This adds strength and exceptional traction. Did we mention the increased turning radius? The new mover design offers unparalleled maneuverability and versatility.

Redesigned Mover Kit

You need to see it to believe it.

For more information on our AGI Batco BCX3 conveyors, talk to one of our ag specialists at your nearest Flaman location or give us a visit and we would be happy to show you what all the buzz is about! We may even let you take it for a spin. Even with winter conditions, we can assure you that you won’t need to worry about getting it stuck!

Posted in New Products | Tagged with conveyor Batco BCX3 grain handling | More articles by Mitch Flaman

A long-distance grain rescue made possible by Bin-Sense

Posted by Jennifer Thompson Oct 14, 2020

You can anticipate grain spoilage as a farmer, but you can never be sure when it’s going to pop up. Or where you’ll be when it does.And what happens if your grain starts to spoil or heat up and you’re nowhere near home, but thousands of kilometers away on a family vacation? That’s what happened to Blake Bergen of 3B Acres in Drake, SK in the fall of 2019 when his Florida vacation was interrupted by news that a canola bin was heating up.

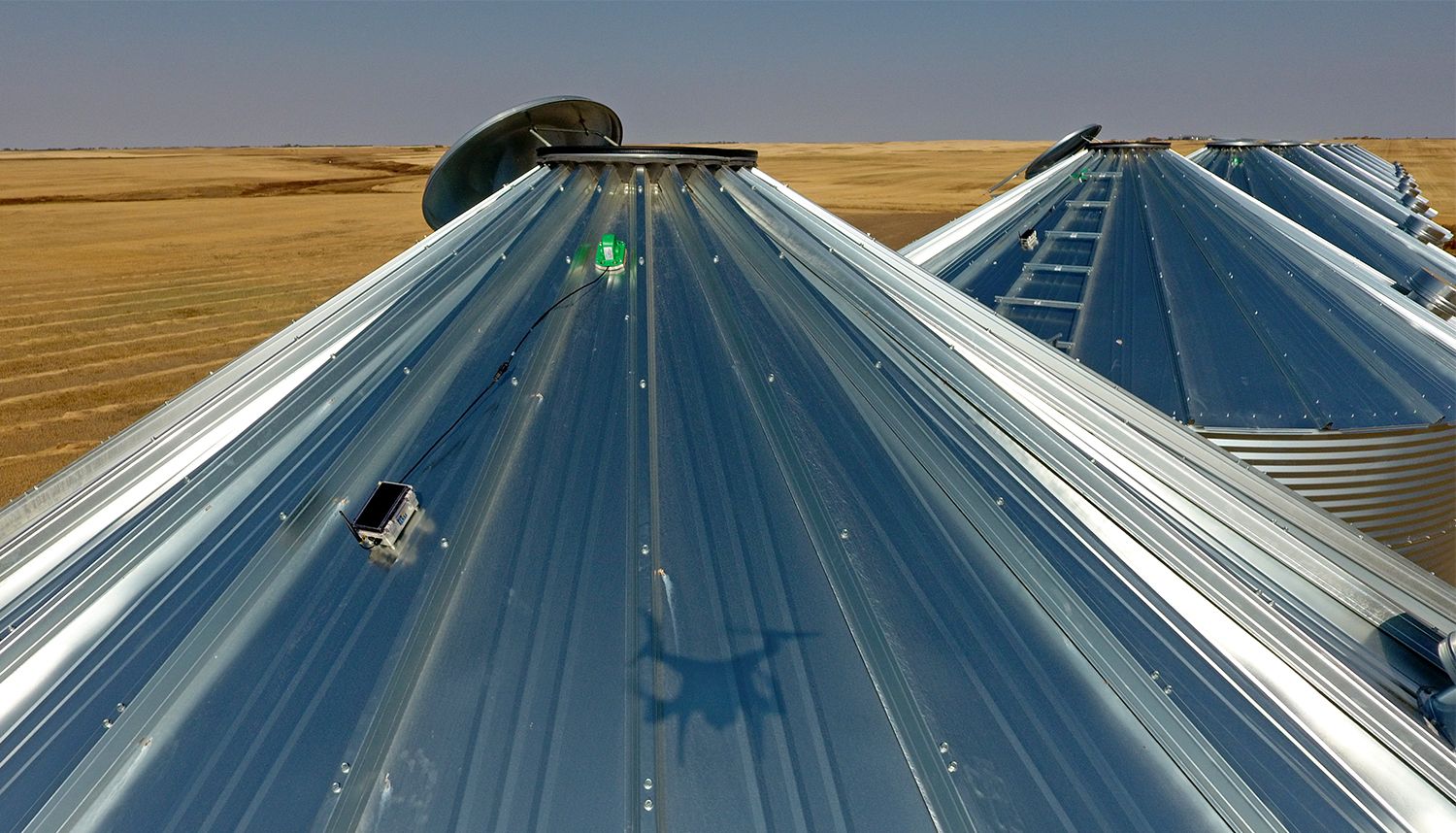

He was getting alerts from his Bin-Sense Live wireless grain monitoring system, an award-winning monitoring system that gives you instant access to your stored grain at any time and from anywhere.

With this system, farmers no longer have to be in the same physical location as their hopper or flat bottom bins to monitor them. They can get valuable information about the grain's quality and stay connected with up-to-date text alerts sent to phone or email.

Those alerts warned Bergen about the situation in his bin, when he otherwise may never have known.

“That bin was not top-of-mind among riskier bins, said Bergen. “We thought we had that one well looked-after so it surprised us when we got the alert.”

Surprised, but not surprised. There were many factors that had led Bergen and his father to install Bin-Sense Live. They had witnessed a dry spring, which led to late crops in July. They also had questions about the storability of straight-cut canola. “We knew we were going to get some stagey canola coming in,” said Bergen. “It wasn’t going to necessarily be swathed at exactly the right time. There was potential for green seeds.”

The Bergens took the proactive approach through grain drying and monitoring. “We thought the odds of having something happen, just the way the crops were looking, were pretty good. We knew if we had a train-wreck, we’d buy a system so it wouldn’t happen again, so why not buy the system before the train-wreck and then it pays for itself?”

In summer 2019, Flaman installed a Live system. Moreover, among their 200,000 bu of monitored grain storage, they also have 42,000 bu worth of hopper bins connected to supplemental heat air drying with temperature and moisture cables monitored by Bin-Sense Live. But it was later that fall when Bin-Sense Live’s communicating technology became critical.

An example of Bin-Sense installed on a bin

“We were going on a two-week vacation to Florida with our extended family,” said Bergen. “On day 1 after landing, we got a chirp on our phone that a bin of canola that had increased in temperature. We decided to watch it for two or three days and could see a constant climb of 1 to 1.5 degrees every day. We phoned home and asked some friends to take a semi-load out of the bin. They took it to the elevator and we saved that bin of canola.”

Even though heat rose in the smallest of bins, the save justified the cost of monitoring the entire yard. “There are lots of misconceptions out there about spoilage and the size of bin,” said Bergen. “I look at grain monitoring as a solid return on investment,” noting that he paid upwards of $17,000 for the system. Saving 5,000 bu of canola, Bergen estimates Bin-Sense Live paid for itself twofold.

He doesn’t spend much time reconsidering the choice between Bin-Sense Live and systems where you check grain on foot. “You can hem and haw about the investment when you have the capability to check your bins manually, but you still have to make a point of doing it. We have 30 bins on the system so it’s more than a three-minute job. It’s a lot of plugging in and downloading. It’s nice to just bring everything up on your phone or your computer and read the colour-coded heatmaps. It’s quick to interpret and see what’s going on.”

So how to thank colleagues who have rescued valuable crops? Blake Bergen squared up, returning from Florida bearing gifts of fine imported bottles. Add the cost to the grain monitoring bill, and he still came out ahead.

Call your local Flaman dealership today to find out more about how Bin-Sense can make sense for your farm.

Posted in Product Information | Tagged with grain monitoring grain bins Bin Sense grain temperature | More articles by Jennifer Thompson

Grain Bag Storage Maintenance Tips

Posted by Calla Simpson Oct 07, 2020

When dealing with a high volume crop, you may decide that short term storage is best to maintain the quality of your harvest. Grain bag storage is a flexible, cost-effective solution for short term storage of bumper yields, provided certain quality control steps are taken. Site preparation, site maintenance, and machine servicing all need to be done properly and timely to ensure your grain holds its quality and value.Below you’ll find tips on the preparation and maintenance steps required to ensure that grain bagging is a successful storage option for your operation.

Site preparation makes for easier maintenance

Selecting the right site for your grain and production is key. It’s best to select a site that is accessible even when the weather is wet, and located in the open to help deter animals. Once an appropriate site has been found, preparing the site is the first step required to set yourself up for easier maintenance.

First, remove any debris such as sticks or sharp objects, then grade the site and ensure the ground is firmly rolled to prevent the grain bags from sinking or water pooling around them. If possible, spray the site with a rodent deterrent to prevent mice and vermin from burrowing under the bags once laid. If proper preparation is not completed, then the bag may not be impervious to air or liquid and can lead to grain spoiling.

Site maintenance once bags are laid and full

The biggest threat to the filled grain bags is animals, especially during the winter months. Snow can create drifts for deer to climb onto the bags, however, using pallets at the ends can deter them. An electric fence, or any sturdy fence, can be used to keep bears and deer away. Year-round, mice pose the biggest risk to the bags as they are known to burrow under, weakening the soil and allowing water to pool, and also chewing through the bag material causing wastage and grain spoilage.

Regular inspections of the bags are needed to ensure no damage from animals, weather, or insects. During wet weather, if the number of mice and vermin are up, then daily bag checks may be required to ensure they stay unharmed. In normal weather conditions, check weekly at a minimum. If there are any punctures, rips, or other damage visible, patching these will prevent moisture from spoiling the grain.

Machine servicing and maintenance

Regular maintenance of Grain Baggers and Grain Extractors helps ensure minimal downtime. Reading and following the manufacturer’s manual is key to keeping these machines in top condition. The manuals describe in detail the following mechanisms and their respective maintenance – the driveline, shear bolts, drive chain tension, and alignment along with the following items needing servicing – fluids and lubricants, auger wear plates, greasing, and servicing intervals. There is also a section on troubleshooting typical issues that can arise such as augers not running, the machine doesn’t move or low unloading capacity.

-----

Discounts available on bulk grain bag orders. For more information, talk to one of our agriculture specialists at your nearest Flaman location.

Posted in Product Information | Tagged with Pro Grain grain bags grain bagging grain baggers grain storage harvest | More articles by Calla Simpson

Move your grain with the all-new AGI Hutchinson Double Run Chain Conveyor

Posted by Paul Boechler Sep 14, 2020

The AGI Hutchinson Double Run Chain Conveyor is a brand new product to the Flaman lineup. It is built in Western Canada with the prairie farmer in mind. Manufactured at AGI’s plant in Swift Current, SK, it is designed to handle delicate crops grown on the prairies, like pulses, far more gently than an auger would.

The UHMW plastic paddles gently convey grain

Maneuverable in Tight Spaces:

Modeled after the clean grain elevator on your combine, its UHMW plastic paddles convey crops to your bin in a gentle manner. A huge benefit of this is the ability to operate at full capacity from nearly any angle, fitting into tighter spaces.

Another feature of the Double Run is the easy to use swivel arc kit, which makes the unit highly portable around the yard. You can move it from bin to bin or dryer, by simply swapping a few pins.

The swivel arc kit allows for easy maneuverability

Low Power Requirements:

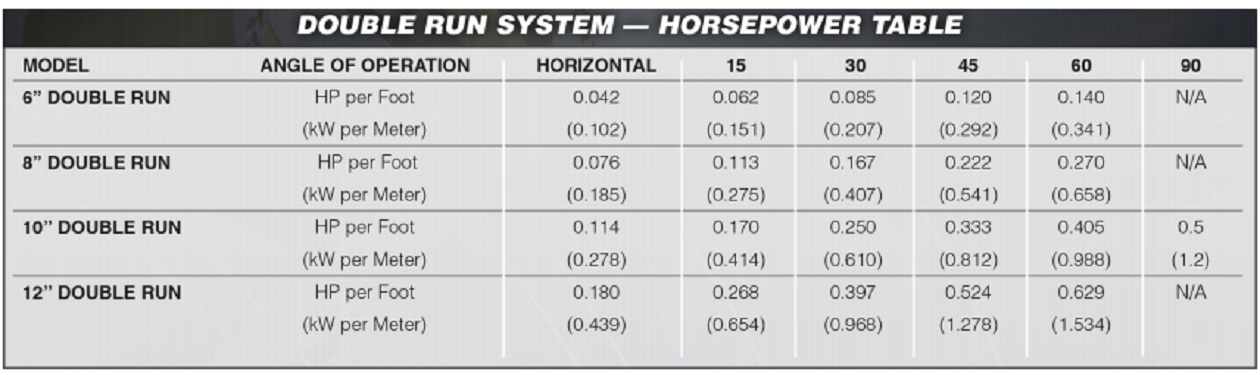

While the Double Run is powerful in getting your grain into the bin, it has a low horsepower requirement compared to alternative grain handling equipment. As an example, 8” model with a length of 82’ requires just 18 HP at a 45° angle (see chart below). These units are available with an electric motor or PTO drive, giving you plenty of power options.

Proven Reliability & Longevity:

We all know an unreliable auger can be a huge problem for your operation at harvest time. The Double Run was designed as a solution to this problem. The chain conveyor requires less maintenance and has more longevity than your typical auger. Keep the chain running straight and tensioned properly, and these units will just run. And run. And run.

Travis Frey of AGI walks us through exactly what makes this unit different:

The Double run comes in lengths of up to 82’ on the 8” and 10” models, with up to 4,000 BPH capacity on the 8” and 6,000 BPH on the 10”. It is also available in a 12” model, which has a 10,000 BPH capacity and lengths up to 130’.

Stop by your local Flaman Ag store or give us a call for more information on this unit.

Posted in New Products | Tagged with AGI Hutchinson Double Run chain conveyor grain handling grain systems Flaman | More articles by Paul Boechler

Beat the Weather with Grain Bagging

Posted by Calla Simpson Sep 11, 2020

The benefits of grain bagging are far and wide, chief among them being the ability to use the weather to your advantage. Since the weather can always turn and change on a dime, it’s important to work around it whenever possible, which is where grain bagging comes in. The airtight, controlled environment inside of a grain bag allows you to store grain and plentiful harvest in a dry space, even when the weather outside is less than ideal. By extending the storage life of your grain, allowing you to store more at once and giving you more flexibility in the way you do so, grain bagging gives people the option to have more options.

Pro Grain Equipment is most passionate about keeping operations running in all weather and situations, saving customers time and money. By grain bagging, you can get your crops off of the field by planning around severe weather to improve efficiency on all sides. The Pro Grain lineup of baggers and extractors work so you can work less, with impressive specs, heavy-duty designs, and improved ease and efficiency for your harvest.

Tip 1: Don’t push the limits of your grain.

Grain bagging allows for safer storage of grain, even during periods of severe weather and freezing temperatures. However, patience is key here. When loading the bags, the weather outside needs to be cool, and the bags should be sealed immediately to ensure that your grain isn’t sitting at a higher temperature than the outside environment. For grain with higher moisture levels, it needs to be dried as soon as possible after the winter season is over. Grain with a lower moisture content can stay in the bags a little bit longer. However, regular temperature monitoring is paramount to making sure that your grain stays in good condition.

Tip 2: Be smart about storage.

Severe weather comes with the territory when farming, and simply when doing anything related to the outside weather. Choosing a storage space that makes sense for your grain is of the utmost importance. When storing grain, look for a place that is highly elevated and away from any sort of drainage that could seep into your bags. You won’t want to store your grain in any manner that could allow natural drainage to affect it, especially during severe storms or periods of melting ice. Before choosing the storage spot for your grain, it should be examined closely to ensure a lack of flooding before severe storms and bad weather. Even though grain bags provide a dry environment for your grain, they can be more susceptible to bad weather — especially if you’re not strategic about placement. You may also want to look into the possibility of grain armor for your grain storage, which gives an extra layer of protection against both weather and wildlife.

Tip 3: Keep a watchful eye on the grain in severe weather.

Grain should be checked periodically, at least once a week, for punctures from severe weather or issues that can arise because of the outside environment. From cosmetic damage that could severely affect the quality of the grain inside to keeping a watchful eye on the temperature of the grain, it’s important to use the weather outside as a gauge for what’s inside your grain bags. By placing the bags in a north to south manner when storing them, the sun will heat the bags evenly for a more consistent environment inside the bags, regardless of the weather.

Tip 4: Be strategic about your timing for a better crop.

One of the biggest benefits of grain bagging is the added ability to increase efficiency by bagging grain right in the field. When you’re expecting severe weather around harvest, grain bagging allows you to control when the crop is loaded into the bags and the condition of the grain. Since grain bagging is a quicker alternative to more traditional means, it allows you to get to your crop before the weather does. Once the grain is in the bag, it’s essentially going to stay the same moisture as when you put it in. By being careful and strategic about your timing, you’ll be able to better store your crop and do so around bad weather.

A Pro Grain bagger in action during Harvest 2019

To learn more about grain bagging and to see which grain bagging products could improve your harvest capabilities, get in touch with us. We would be happy to walk you through everything you require for your grain bagging needs and answer any questions you might have.

-----

Now offering discounted pallet pricing when you buy four or more pallets of grain bags. For more information, talk to one of our agriculture specialists at your nearest Flaman location.

Posted in Product Information | Tagged with Pro Grain grain bags grain bagging grain baggers grain storage harvest | More articles by Calla Simpson

Reduce labour when filling bins: Automate your grain handling site with a Walinga Blower System

Posted by Calla Simpson Aug 31, 2020

A Walinga Pneumatic Blower System may be one of the most versatile pieces of equipment you can add to your Grain Handling lineup. The Ultra-Veyor is designed to fill bins of various heights and distances from the ground up, allowing you to easily add the system to any pre-existing site.

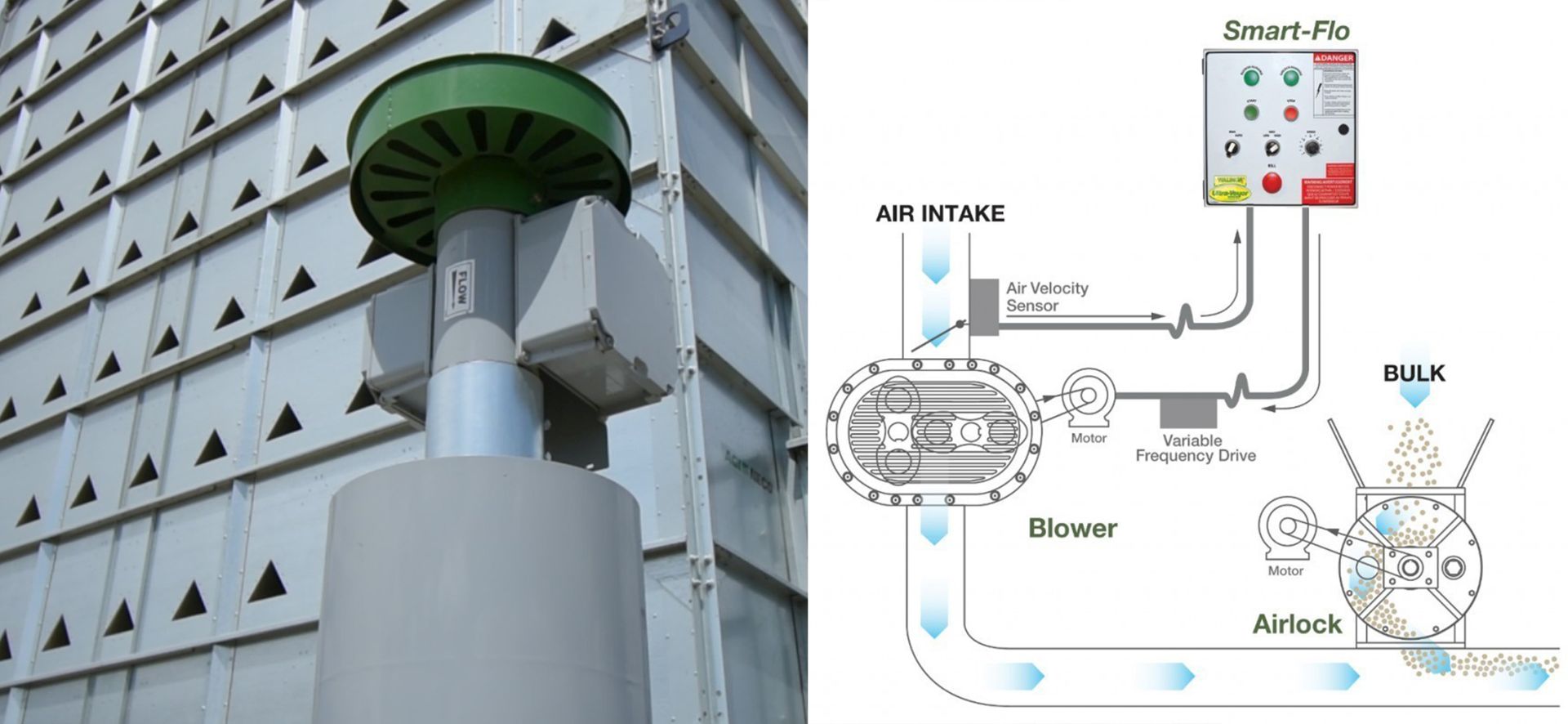

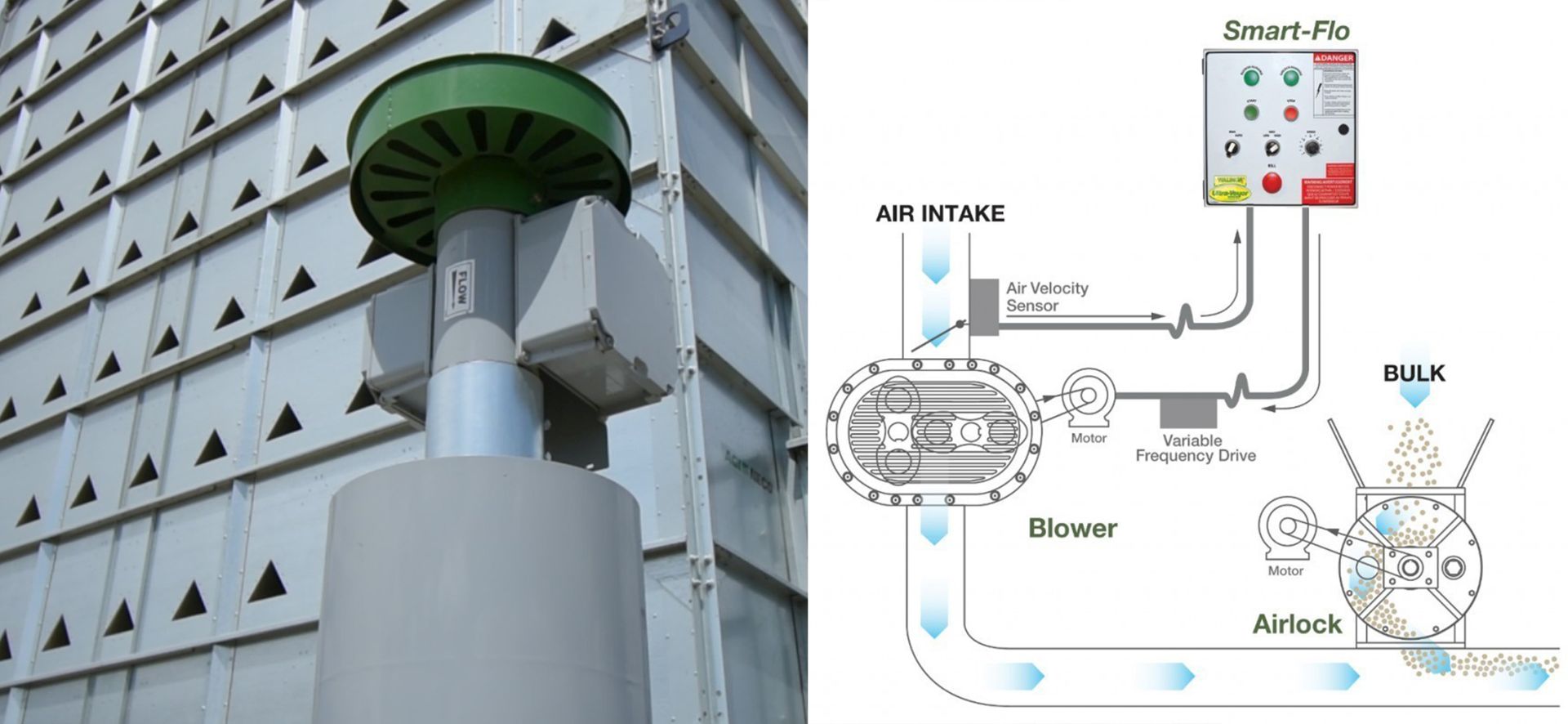

Walinga Sales Rep Doug Termeer explains how a blower system works

Many yard sites weren’t originally designed with the thought of adding a grain handling system or grain dryer down the line. As farms continue to grow, larger bins are being installed and grain storage is being built further and further away. The only way to hit all these bins of different sizes and distances economically is with a blower system. By allowing you to keep the current bins and other infrastructure you have already invested in, a Walinga Ultra-Veyor prevents you from having to redesign your entire yard site – saving you a lot of money in the long run.

A grain handling setup in Saskatchewan utilizing a Walinga blower system to reach bins of various heights

A grain handling setup in Saskatchewan utilizing a Walinga blower system to reach bins of various heights

Walinga blower systems are also very flexible and expandable, so you don’t need to have your whole yard designed and planned out ahead of time. You can easily expand down the road as your business grows and you start to add more acres or dry more grain. These systems can be installed under driveways to reduce the risk of damaging any pipes as you load/unload trucks in your yard.

The Walinga Ultra-Veyor is also a great add-on to any grain dryer, especially continuous flow dryers like NECO. Automating your grain dryer and grain handling reduces the number of augers, legs, and additional trucking necessary to move grain around your yard. This maximizes accessibility to any drying or storage facility. Your grain can go straight from the dryer into the final storage bin, so you don’t have to move it around multiple times before you get it where you want it in the end. It’s faster, more efficient, and most importantly, safer.

A NECO Grain Dryer unloading into a Walinga system

With the Smart-Flo feature on your Walinga blower, you have the ability to control the airspeed which reduces unnecessary damage to product and piping. This Variable Frequency Drive (VFD) system monitors and adjusts motor speeds depending on crop type, volume of product, and distance – optimizing performance and reducing energy costs. The Smart-Flo system can also be wired into your continuous flow grain dryer to speed up and slow down as necessary.

A blower system is not only an economic and affordable solution for long-distance conveying, it is also simple to install and is gentle on product – moving grain virtually dust and damage-free. Walinga Ultra-Veyors can move anywhere from 400 bushels/hour to 2,100 bushels/ hour, depending on the size of your operation.

Hear first-hand how a Walinga Ultra-Veyor made a positive impact on this customer's operation

Want to invest in a Walinga Pneumatic Blower system and automate your grain handling site this year? Contact us to schedule a free, no-commitment site assessment today.

-----

For more information on our grain handling and grain drying solutions, talk to one of our agriculture specialists at your nearest Flaman location.

Posted in Product Information | Tagged with grain systems grain handling Walinga Ultra-Veyor blower system NECO grain dryer | More articles by Calla Simpson

Reduce labour when filling bins: Automate your grain handling site with a Walinga Blower System

Posted by Calla Simpson Aug 31, 2020

A Walinga Pneumatic Blower System may be one of the most versatile pieces of equipment you can add to your Grain Handling lineup. The Ultra-Veyor is designed to fill bins of various heights and distances from the ground up, allowing you to easily add the system to any pre-existing site.

Walinga Sales Rep Doug Termeer explains how a blower system works

Many yard sites weren’t originally designed with the thought of adding a grain handling system or grain dryer down the line. As farms continue to grow, larger bins are being installed and grain storage is being built further and further away. The only way to hit all these bins of different sizes and distances economically is with a blower system. By allowing you to keep the current bins and other infrastructure you have already invested in, a Walinga Ultra-Veyor prevents you from having to redesign your entire yard site – saving you a lot of money in the long run.

A grain handling setup in Saskatchewan utilizing a Walinga blower system to reach bins of various heights

A grain handling setup in Saskatchewan utilizing a Walinga blower system to reach bins of various heights

Walinga blower systems are also very flexible and expandable, so you don’t need to have your whole yard designed and planned out ahead of time. You can easily expand down the road as your business grows and you start to add more acres or dry more grain. These systems can be installed under driveways to reduce the risk of damaging any pipes as you load/unload trucks in your yard.

The Walinga Ultra-Veyor is also a great add-on to any grain dryer, especially continuous flow dryers like NECO. Automating your grain dryer and grain handling reduces the number of augers, legs, and additional trucking necessary to move grain around your yard. This maximizes accessibility to any drying or storage facility. Your grain can go straight from the dryer into the final storage bin, so you don’t have to move it around multiple times before you get it where you want it in the end. It’s faster, more efficient, and most importantly, safer.

A NECO Grain Dryer unloading into a Walinga system

With the Smart-Flo feature on your Walinga blower, you have the ability to control the airspeed which reduces unnecessary damage to product and piping. This Variable Frequency Drive (VFD) system monitors and adjusts motor speeds depending on crop type, volume of product, and distance – optimizing performance and reducing energy costs. The Smart-Flo system can also be wired into your continuous flow grain dryer to speed up and slow down as necessary.

A blower system is not only an economic and affordable solution for long-distance conveying, it is also simple to install and is gentle on product – moving grain virtually dust and damage-free. Walinga Ultra-Veyors can move anywhere from 400 bushels/hour to 2,100 bushels/ hour, depending on the size of your operation.

Hear first-hand how a Walinga Ultra-Veyor made a positive impact on this customer's operation

Want to invest in a Walinga Pneumatic Blower system and automate your grain handling site this year? Contact us to schedule a free, no-commitment site assessment today.

-----

For more information on our grain handling and grain drying solutions, talk to one of our agriculture specialists at your nearest Flaman location.

Posted in Product Information | Tagged with grain systems grain handling Walinga Ultra-Veyor blower system NECO grain dryer | More articles by Calla Simpson

Early season utilization: Increase the grade of your grain with a NECO Grain Dryer

Posted by Calla Simpson Aug 26, 2020

As harvest is well underway in most areas of the province, many producers are utilizing their grain dryers early on this season and increasing the available window to combine. Some farmers have even noticed increases in their durum quality as their grade improves after drying.

20% moisture durum before going into the NECO grain dryer (left) and 14.5% moisture durum after being dried (right)

20% moisture durum before going into the NECO grain dryer (left) and 14.5% moisture durum after being dried (right)

Nolan Gettis, a farmer in central Saskatchewan, discusses how his NECO Grain Dryer has improved his operation:

“Two years ago, I would have been waiting to combine saying, ‘It’s getting close’. Right now, I’m full on harvesting because I have this dryer as a tool. I’m not waiting to use it. I’m literally taking off 20% durum and it’s coming out dry and just shining. It’s amazing how much better this durum looks once it comes out of that dryer. When you have a crop of unicorn #1 amber durum, you’ve gotta go get it.

I’d have to say the biggest benefit of this NECO dryer is that we’ve taken on more acres this year and I’ve already conquered that land without buying another combine. I have three bins on the go; a dry bin, an aeration bin, and the dryer. It’s a total harvest management tool.”

Nolan's grain drying setup in Semans, SK

Mixed flow dryers reduce the risk of crop damage, resulting in higher test weights. This drying process helps mature the kernels and brings out the rich colour evenly, producing higher quality grain with more consistent results. This dramatic difference in quality increases profitability and improves yield.

It's not too late – contact us to book your dryer install with Flaman today.

-----

For more information on our grain handling and grain drying solutions, talk to one of our agriculture specialists at your nearest Flaman location.

Posted in Product Information | Tagged with grain systems grain handling grain drying NECO grain dryer mixed flow continuous flow | More articles by Calla Simpson

Early season utilization: Increase the grade of your grain with a NECO Grain Dryer

Posted by Calla Simpson Aug 26, 2020

As harvest is well underway in most areas of the province, many producers are utilizing their grain dryers early on this season and increasing the available window to combine. Some farmers have even noticed increases in their durum quality as their grade improves after drying.

20% moisture durum before going into the NECO grain dryer (left) and 14.5% moisture durum after being dried (right)

20% moisture durum before going into the NECO grain dryer (left) and 14.5% moisture durum after being dried (right)

Nolan Gettis, a farmer in central Saskatchewan, discusses how his NECO Grain Dryer has improved his operation:

“Two years ago, I would have been waiting to combine saying, ‘It’s getting close’. Right now, I’m full on harvesting because I have this dryer as a tool. I’m not waiting to use it. I’m literally taking off 20% durum and it’s coming out dry and just shining. It’s amazing how much better this durum looks once it comes out of that dryer. When you have a crop of unicorn #1 amber durum, you’ve gotta go get it.

I’d have to say the biggest benefit of this NECO dryer is that we’ve taken on more acres this year and I’ve already conquered that land without buying another combine. I have three bins on the go; a dry bin, an aeration bin, and the dryer. It’s a total harvest management tool.”

Nolan's grain drying setup in Semans, SK

Mixed flow dryers reduce the risk of crop damage, resulting in higher test weights. This drying process helps mature the kernels and brings out the rich colour evenly, producing higher quality grain with more consistent results. This dramatic difference in quality increases profitability and improves yield.

It's not too late – contact us to book your dryer install with Flaman today.

-----

For more information on our grain handling and grain drying solutions, talk to one of our agriculture specialists at your nearest Flaman location.

Posted in Product Information | Tagged with grain systems grain handling grain drying NECO grain dryer mixed flow continuous flow | More articles by Calla Simpson

How to Address Farming Challenges with the Right Equipment

Posted by Calla Simpson Aug 20, 2020

With grain bagging at your side, farming challenges won’t loom over your head.

As we begin to enter the new days of the upcoming farming season, there’s one constant: the harvest challenges that will lie ahead. A huge part of being in the farming business is being able to anticipate challenges and to pivot to them, and every good farmer understands that. However, every good farmer also desires to rise above the challenges presented to them, which is where the right equipment and the right mindset come into play.

In the 2019 harvest season, we saw challenges ranging from supply chain management issues and an excess of labour costs to late harvest starts, inclement fall weather, the prediction of lowered storage availability, and an abundance of leftover crops. As the 2020 season begins to come to shape overhead, it’s our job as farmers to think ahead and problem solve the best way we know how.

A great way to pivot and stay on top of things is through the use of grain bags, which have been a huge help to farmers looking for ways to minimize cost along with improving harvest efficiency.

Challenges farmers are facing in 2020

The 2020 harvest season is a unique one as the COVID-19 pandemic hit the globe and affected each and every farm operation. As farmers, the job is always to continue harvesting and providing for others — which can sometimes prove to be a hard thing. As we enter a new season, the issues facing farmers are:

Storage: there is a struggle to find adequate storage space for grain and harvest amid the pandemic.

Supply Chain Issues: stemming from a lowered labour force and leftover grain.

Inventory: confusion in inventory forecasting.

Physical Distancing: the need for physical distancing and increased health measures among labour forces on farms.

How can grain bags help farming challenges?

Flexibility is everything when it comes to farming, whether it be through finding new storage methods or by looking for new ways to cut costs. By using grain bags in your farming operation, you’ll be able to deal with many of the common farm operation challenges that harvesters are facing in 2020.

You’re also able to maximize space and minimizing risk (both financially and personally). The addition of grain bagging equipment and grain bags leads to optimized space on your farm, as well as a lowered need for labour, grain transportation, and grain storage. Here’s how:

Flexible Storage: grain bags allow you to store your harvest directly on your land, completely eliminating the need for extra labour to transport and store grain externally.

Reduced Costs: grain bags simply cost less than other grain storage methods — up to 2/3 less — making them a no-brainer when it comes to downsizing costs in your farming operation.

Increased Productivity: grain bags allow for better time management in your harvesting operation, from less downtime on the combines to more productivity from the workforce at hand.

Harvest Faster: grain bags are helpful when it comes to supply chain issues and excess crops, as they’ll keep your harvest safe from wildlife, spoilage, and weather while you wait.

Increased Efficiency: grain bags help to deal with varied demand, as they offer both efficiency and storage to assist with your needs.

When it comes to challenges, farmers are no stranger to making it work. Farmers are more able to pivot than any other profession in the world, whether it be from weather, cost, or even global pandemics. With grain bags, you’ll be able to take some pressure off of your shoulders when it comes to incoming farming challenges.

-----

Now offering discounted pallet pricing when you buy four or more pallets of grain bags. For more information, talk to one of our agriculture specialists at your nearest Flaman location.

Posted in Ag news | Tagged with Pro Grain grain bags grain bagging grain baggers grain storage harvest | More articles by Calla Simpson

Tips and Resources for a Safe Harvest

Posted by Jennifer Thompson Aug 17, 2020

As harvest begins to start in many parts of Western Canada, Flaman is here to provide the tools and equipment you need to get your crop off quickly and safely. Along with our wide variety of Harvest Helpers to aid you in your work, we’ve collected some important and useful safety tips for harvest time. We want to make sure all our customers return safely from the field and have the resources to support their employees and family members on the farm.

This post will look at 4 main types of safety:

- Grain bin entrapment

- Fire safety and prevention

- Machinery and power lines

- COVID-19 safety

Grain Bin Entrapment

Tough grain is one of the leading causes for producers to enter a bin. Many studies have shown that entering a bin to break up spoiled grain while operating unloading equipment is the leading cause of grain entrapment. A person could become completely covered within 20 seconds. Across Canada, there’s an average of six fatalities every year from grain entrapment or engulfment.

If you need to enter a bin to asses grain, there is a Grain Bin Assessment chart from the Canadian Agricultural Safety Association you can use to assess if it’s safe to enter the bin.

This fact sheet from the Canadian Centre for Health and Safety in Agriculture also has some helpful information about how grain entrapment occurs, as well as preventative and safety measures.

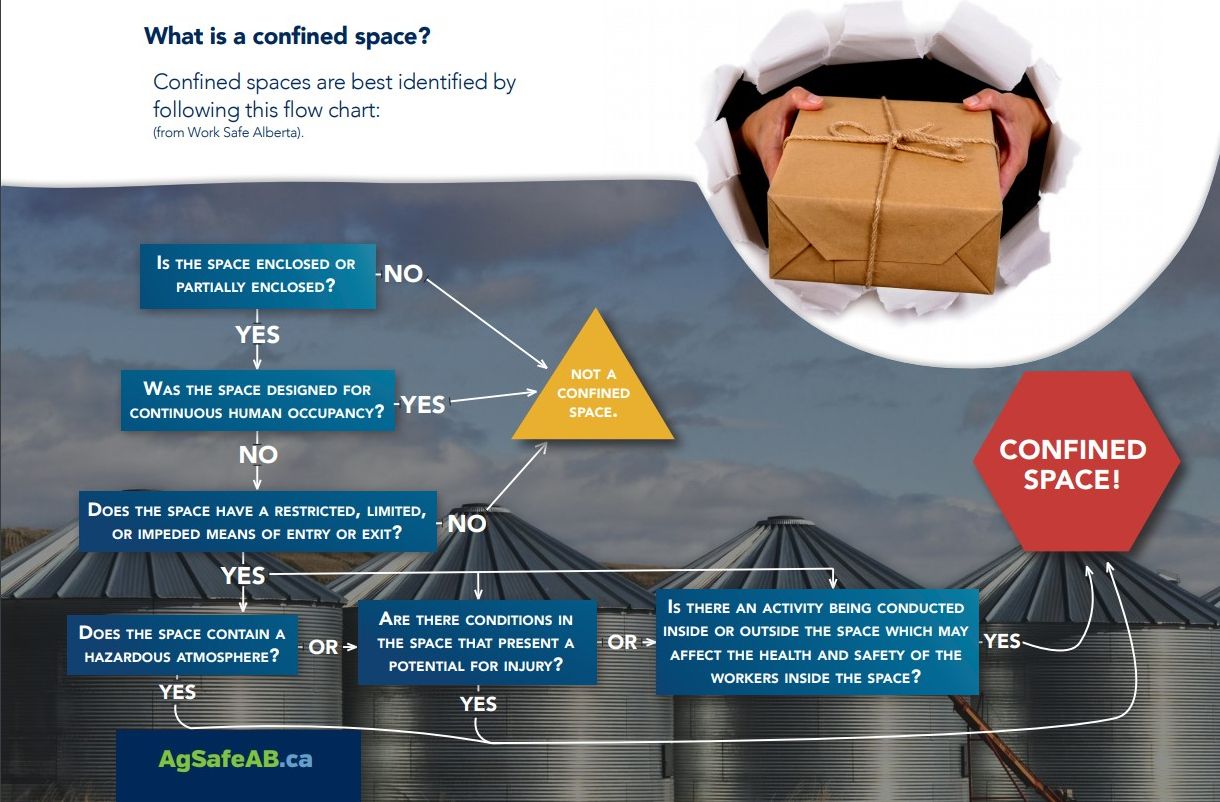

And finally, if you wish to create a Confined Space Management Program for your farm, this quick start guide from Ag Safe Alberta is a useful tool. Along with grain bins, confined spaces also include sumps, wells, feed bins, attics and even some equipment.

Fire Safety and Prevention

Fires in the field can happen all too suddenly when working with dry, flammable material and hot mufflers and electrical wiring. There are some simple pre-cautionary measures you can take to help avoid the risk of injury or loss of equipment due to fire.

- Have working fire extinguishers mounted on equipment, ideally one in the cab and one accessible from the ground. Alberta Agriculture recommends a 10 pound dry chemical, multi-purpose ABC extinguisher and a 2.5 gallon pressurized water extinguisher on combines.

- Remove crop residue, dust, debris, dirt and excess lubricant around all heat sources regularly. Check for a buildup of combustible crop residue around engines and exhaust systems, concealed drive belts and pulleys that can overheat due to friction.

- Be careful when using low clearance vehicles in fields, as exhaust pipes and catalytic converters can ignite dry grass or stubble.

- Check exposed wiring and fuel/hydraulic lines for damage, wear and deterioration.

- Allow engines to cool before refueling.

And for added safety, Flaman carries a variety of firefighting pump and tank units, such as the BE Fire kit or the Fire Skids, to allow you to quickly put out any fires in the field while harvesting.

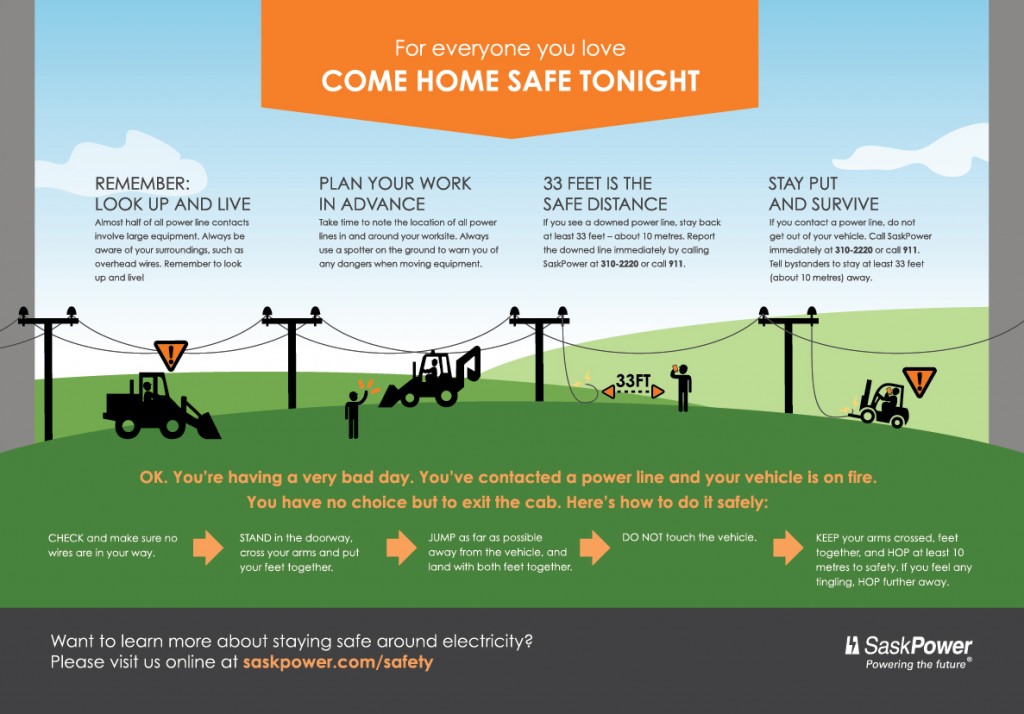

Machinery and Power Lines

Electrical safety is another important area to be aware of when working with large machinery on a farm. More than 40% of agricultural workers in Canada have reported direct hits or near misses with power lines. In 2019, there were 326 farm safety incidents reported to Sask Power. The most common causes of electrocutions on the farm are portable grain augers, large combines, high clearance sprayers and other tall equipment that can come into contact with overhead power lines.

There are two types of electrical injury that can occur:

- Electric shock, when electric current passes through the body causing injury or death.

- Arc flashes: a blast of energy caused by an electric arc, which can produce sounds waves, extreme heat, shrapnel and more, This can lead to lung injuries, ruptured ear drums, burns, blindness or death.

This guide “Electrical Safety on Saskatchewan Farms" from Sask Power talks about potential risks and hazards and offers safety tips, guides and checklists to make sure you and your workers come home safe. Or you can print out this Farm Safety Checklist to make sure everyone knows how to avoid overhead lines and what to do if an accident occurs.

COVID-19 Safety

This year, farming operations will have the added tasks of protecting workers and their family from COVID-19. As an essential service, we recognize that farmers must continue to work to grow our food and feed our country.

Along with the general pre-cautions such as hand washing, physical distancing, cleaning of work attire and wearing gloves, this fact sheet from the Canadian Centre for Occupation Health and Safety offers many safety tips specifically for the agricultural industry in areas such as:

- Transportation

- Sanitation

- Group Living and Residence Recommendations

- Team and Site Management

- And much more.

For those interested in creating an overall safety plan for their operation, this workbook from Ag Safe Alberta lays out the steps to create your own Farm Safe Plan.

Posted in Ag news | Tagged with harvest safety farming grain bins electrical safety | More articles by Jennifer Thompson

The Top 10 Reasons to Use Grain Bags

Posted by Calla Simpson Aug 04, 2020

Grain bagging has been gaining acclaim and popularity among farmers for being a resourceful, flexible, and time and money-saving grain storage option. The benefits are many, and farmers appreciate the efficiency of this innovative storage technique.

If you bag grain, you can expect to experience the following 10 benefits during your harvest season:

1. Saves the farmer's time.

When you bag grain, you reduce time loading grain into trucks and transporting it to grain bins or elevators. You can harvest the grain and store it right there in the field, which drastically cuts down on work time by eliminating so much back and forth to older, more traditional storage containers.

2. Increases harvest efficiency.

Grain bagging is easily the most flexible and efficient method for storing grain. You can store the bags anywhere that’s convenient (field, farm, or other lots), you have unlimited capacity, you have fewer labour constraints, you can move grain faster, and you can segregate grain variety easily into different storage bags. Overall, the processes during harvest are completely streamlined and made as productive as possible with grain bagging.

3. Improves commodity marketing.

Grain bagging preserves grain due to the ideal environment for grain within the bags themselves. When the bags are sealed, they are airtight, which eliminates the need for preservative chemicals and retains the grain quality. If commodity prices are low, and where storage constraints exist, bagging provides flexible unlimited storage. This allows farmers to control and plan the right time to market the crop for top dollar.

4. Reduces labour problems.

Because fewer trucks are required with grain bagging, your labour inefficiencies and costs will naturally reduce. Grain can be stored in the field where it’s bagged, which lowers the need for additional labourers.

5. Provides a storage solution for rented land.