Flaman Rentals Blog

RSS feed

Categories

Recent activity

- What's it like being a Flaman Rental Dealer?

- A Brief History of the Newest Flaman Store in Swift Current

- Disney's NEW Leadership Excellence Training Course

- Disney's Approach To Quality Service

- Disney's Approach To Quality Service

- Trailering 'Rules of the Road' Updated

- 10th Annual Frank J. Flaman Foundation Gala 2016

- Why Frank Cares

Authors

Archive

You Asked for Diesel.

Posted by Jeff Brown Mar 14, 2024

.jpg)

The Flaman Custom-Build team has finished work on our first Hatz Diesel powered Meridian 12 x 39 Auger. We’re excited to say that the test results have been impressive. Everything ran smooth as silk – operating quietly, while delivering loads of power. So, this Spring, we’ll build more diesel ready Meridian augers and conveyors for our customers.

You’ll soon be able to see them at select stores. For now, we wanted to share our excitement with a sneak peek, along with some of our team's favourite features.

In the words of Curtis Trumier from the production team,

” Every time the conversation comes up with customers about cold starts, the answer is always, ‘We should have bought a diesel engine.’ Well, now they can!”

.jpg)

Cold Weather Start

Engine intake pre-heater and circulating block heater.

"A diesel engine has twice the torque as a gas engine. That’s a huge plus, and the inline-block heater will be excellent for cold-weather starts. Customers tell me their diesel engine will, on average, outlast three-grain augers.

Sheldon Sleeva (Yorkton)

.jpg)

Real Power

24.7 HP Hatz diesel with 90ft/lbs of torque delivers over twice as much torque as a 40 HP gas option.

"My customers have been asking for a diesel option for forever. Gas engines don't like to start in the winter, they blow seals, and bigger augers are underpowered with gas. A diesel option just has more power. This is a unique option at a great price point."

Phil Flaman (Southey)

Robust Auger Frame

A reinforced auger frame designed to handle the weight of a powerful diesel engine.

"For years, my customers have asked for an affordable load-out auger option with a diesel engine. It’s great knowing we can offer this option to customers frustrated with their gas engines. I know a diesel engine will outlast the auger, and I appreciate our build team reinforcing the auger frame for added stability.

Darrell Knash (Yorkton)

.jpg)

No Fail Hand Clutch

Soft start hand clutch for years of bulletproof operation. No expensive electric clutch to fail.

I always get phone calls about the electric clutches quitting. Whether it’s due to the clutch or the soft start module failing, replacing these parts is very expensive. Having the manual hand clutch eliminates all electrical problems and will save money down the road.

Curtis Trumier (Prince Albert)

Our production team in Prince Albert has done an incredible job with our first diesel-powered auger and will begin building more for sale at select stores. Interested in seeing one in action? Contact your local Flaman representative.

Posted in Product Information | Tagged with Meridian Diesel Auger | More articles by Jeff Brown

Grain Cart Unloading Done Just Right

Posted by Jeff Brown Jun 16, 2022

It really does matter how you look at it. Watching those harvest bushels pour out of your auger may do your heart good, but your back and neck don’t fare so well.

That’s because traditional grain carts unload on the left-hand side, causing you to turn away from your tractor controls. Meanwhile, anyone in your buddy seat has to do his own contortions to stay out of your way while you try to accurately offload grain. All that straining and stretching to see what’s happening makes for a long, unpleasant day - and a sore, sleepless night.

Thankfully, one simple common-sense improvement gives you a clear view of your auger without the aches and pains.

Right-side augers change everything!

J&M Manufacturing’s right-side auger grain cart makes the most of your tractor’s cab layout. Easy access to controls and unobstructed visibility allow you to effortlessly aim your auger right into the semi-trailers. The increased comfort makes grain handling more operator-friendly— with fewer visits to the chiropractor.

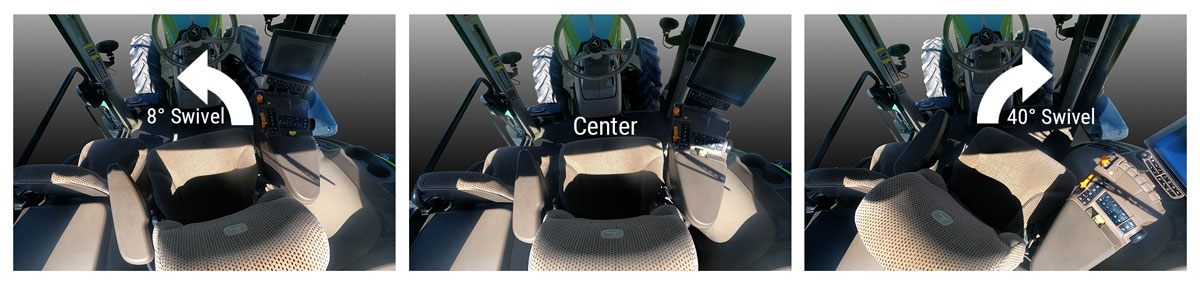

It works with the extended right-hand swivel of most tractor seats and provides a consistently clear view of your controls and monitors. No more groping around, hitting the wrong button, and spilling your valuable grain.

Farmer Approved

Operators have noted the left-to-right change left them less fatigued at the end of the day.

“It's hard to look to your left when your controls are on the right. It’s just a piece of cake.”

Bill Carter, Carter Farms

Different Side. Same Great Quality.

J&M builds their right-side auger model to the same high-quality standards as the rest of their grain cart line. All components and wearable parts remain as durable, dependable, and available as ever. Only the auger position has changed, and it's just one of this cart’s outstanding features.

Speed, Accuracy, and Convenience

The X-tended reach straight auger enables you to transfer 1400 bushels of grain in 2.5 minutes. Meanwhile, J&M’s patented telescoping hydraulic flow control spout sharpens your offloading aim – reducing the amount of grain that spills on the ground.

A 3-position auger system offers a 'storage' position to reduce machine width during transport and parking. The 'field' position limits stress on the auger and keeps the auger clean of any mud. The auger quickly extends to the 'unload' position to drop grain off.

J&M Grain Carts at Flaman

Flaman carries the J&M 1412 grain cart with single 32” wide wheels or a 36” V4 Track to reduce soil compaction. Other heavy-duty standard components include:

- V-Truss axles designed for strength, preventing twisting or bending

- Oversized 6” spindles

- 10-bolt and 20-bolt hubs available

- Computer-balanced bullet auger flighting for quick unload speed and durability

All of our 1412 X-tended reach right-side auger grain carts will be wrapped with special edition Canadian decals, and will feature an iFarm scale, rolling tarp, and 1 ¾" PTO drive.

------

Numbers are limited for 2022. Contact your nearest Flaman Ag expert and reserve your new J&M right-side auger grain cart today!

Posted in New Products | Tagged with J&M grain carts right side auger x-tended reach grain handling harvest | More articles by Jeff Brown

When the elevator calls on a cold day, will your auger be ready? Take these tips for a dependable cold weather start

Posted by Mitch Flaman Feb 11, 2021

With the cold weather snap we've been having, I'm reminded that my dad always said, "Things just start breaking down and don't work well after -25". That being said, you don't always have the luxury of taking a day off when the elevator calls for grain in the middle of winter. In case you're in a rush and it's too cold to fire up the auger to load the trucks, take a few minutes and remind yourself of a couple of key tips to ensure that your auger or conveyor starts when you need it to..jpg)

Fuel

Fuel problems always seem to show up when the cold hits. The two most common fuel problems are:

1. Old/dirty fuel

2. Water in the fuel

Make sure you are always using good clean fuel. Check your fuel filters often, and replace them when necessary. It's the easiest way to ensure the auger engine will start easy and run clean at a cold, crucial time. The last thing you want when you're in a rush is pausing to clean the carb or rip the engine apart. If you're not sure how old the fuel is in the jerry can you're about to use, you're better off using it for a bonfire. Go get some new stuff and prevent the headache.

Water in fuel is as bad as dirty or old fuel, and sometimes worse. Because water is heavier than fuel, it will usually find its way to the bottom of the tank, often where the fuel line feeds the carburetor. And you can be sure that it will either freeze up when it's cold or prevent the motor from igniting when you need it to most. If there is a drain valve on your auger, it is recommended you periodically drain the fuel in the spring or when the unit is warmed up in the shop. Fuel additives such as Sea Foam or isopropyl-based gas line antifreeze can also help mitigate the problems old or water-based fuel can pose on engines.

EFI vs Carbureted EnginesMost farms have augers or conveyors with both carbureted and EFI (electronic fuel injection) motors. Although they operate very much the same, the starting procedure may differ.

On a carbureted engine, add a small amount of throttle to ensure the engine will idle, pull the choke fully out and start to crank the motor over. Be sure not to over-throttle and flood the engine. Once the motor fires and runs for a few seconds, you can usually push the choke in half-way and let the engine warm-up for 5-15 minutes. After the engine is good and warm, you can push the choke in all the way and you should be good to go.

When cold starting an EFI engine, there are a couple other things to consider. Set the throttle to approximately one-third open (between idle and one-half throttle), turn the key on, and watch for any lights on the control panels. This will ensure everything is powering up. Listen for a humming sound to confirm the electric fuel pump is working. After the pump kicks in, fully turn the key to the start position and start cranking the engine over. If it stalls or does not start after a few seconds, cycle the key to the off position, and repeat this step. Wait for the electric pump to kick in again and start cranking the engine over. This may need to be repeated multiple times. Once the engine is idling and running, allow 5-15 minutes for it to warm up before putting any load on it.

Following the tips above will ensure you the best chance of making sure your auger/conveyor starts in the cold weather. Sometimes it is just too cold for an engine to start regardless of what prep work you do. In that case, it might be time to go inside where it's warm, and browse for a new auger with modern technology and new, clean fuel in the tank!

-----

For more information on our grain handling equipment, auger accessories, or to learn more about cold starting an engine, talk to one of our agriculture specialists at your nearest Flaman location.

Posted in Product Information | Tagged with auger conveyor engine EFI carburetor cold start | More articles by Mitch Flaman

Move your auger or conveyor safely with the Lift-EZ Hydraulic Jack

Posted by Jennifer Thompson Jun 30, 2020

If you’ve ever moved grain with a conveyor or auger, you know that standard screw jacks can be inconvenient and a hassle to hook up and connect with your tractor. And if you’ve ever said to yourself “there has to be a better way,” then you’re not alone. The Lift-EZ Hydraulic Jack is a safe and convenient way to connect your auger or conveyor to your tractor

We spoke with the product’s inventor, Bret Watson, the operations manager at Flaman’s Swift Current location, about where the idea for this product came from, and why every farmer could use one.

Tell me where the idea for this hydraulic jack came from?

Bret: I invented it two years ago with Bob Schafer. Bob has a service company that deals with farmers, and his customers were having trouble with their jacks getting damaged. They needed another option.

Bob and I were having coffee one day and we said to ourselves, “this is something we could do.” Bob is a mechanic by trade, and I have an engineering degree and manufacturing background. Hydraulics are readily available on back of a tractor so that’s why we chose that route.

What was the creation process like?

Bret: We started with some drawings on a piece of paper, then I used CAD to develop it and make a prototype. Then we fine-tuned it to make sure it was user-friendly. From concept to completion it took about 3-4 months.

Tell me about the jack and what makes it different.

Bret: With this jack, the farmer can back up to auger/conveyor, connect the jack hoses and then safely lower/raise the unit from the cab of his/her tractor. They can easily get everything aligned, then slide in the implement pin, raise the Lift-EZ jack and then they’re good to go. It uses the hydraulics that tractors already have, so it’s easy to add on. I haven’t seen anything like this for farm use before.

Tell me about the added safety features of this hydraulic jack.

Bret: The jack comes with a hydraulic safety valve, so if there is any damage to any hydraulic hose the jack won’t come down. You can adjust the jack from your seat safely. When you get out of the tractor, you don’t have to worry about the jack creeping down, the valve locks it and won’t allow it to come down unexpectedly, which of course could be very dangerous.

Can this jack go on any auger or conveyor?

Bret: Yes, it can be retrofitted to any auger or conveyor. The jack stub can be mounted at any height in order to replace any standard screw jack. It’s very user-friendly.

What inspires you to invent products like this?

Bret: I’m driven by solving problems and safety. This product came right from a farmer’s need. It’s a safer product and something that will help them.

The Lift-EZ Hydraulic Jack will be available at most Flaman locations in Saskatchewan. Please call your local Saskatchewan store to ask about availability or to speak to a product specialist.

Posted in Product Information | Tagged with jack hydraulic jack auger conveyor safety | More articles by Jennifer Thompson

Locations

Locations